Are you a seasoned Aircraft Sheet Metal Mechanic seeking a new career path? Discover our professionally built Aircraft Sheet Metal Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

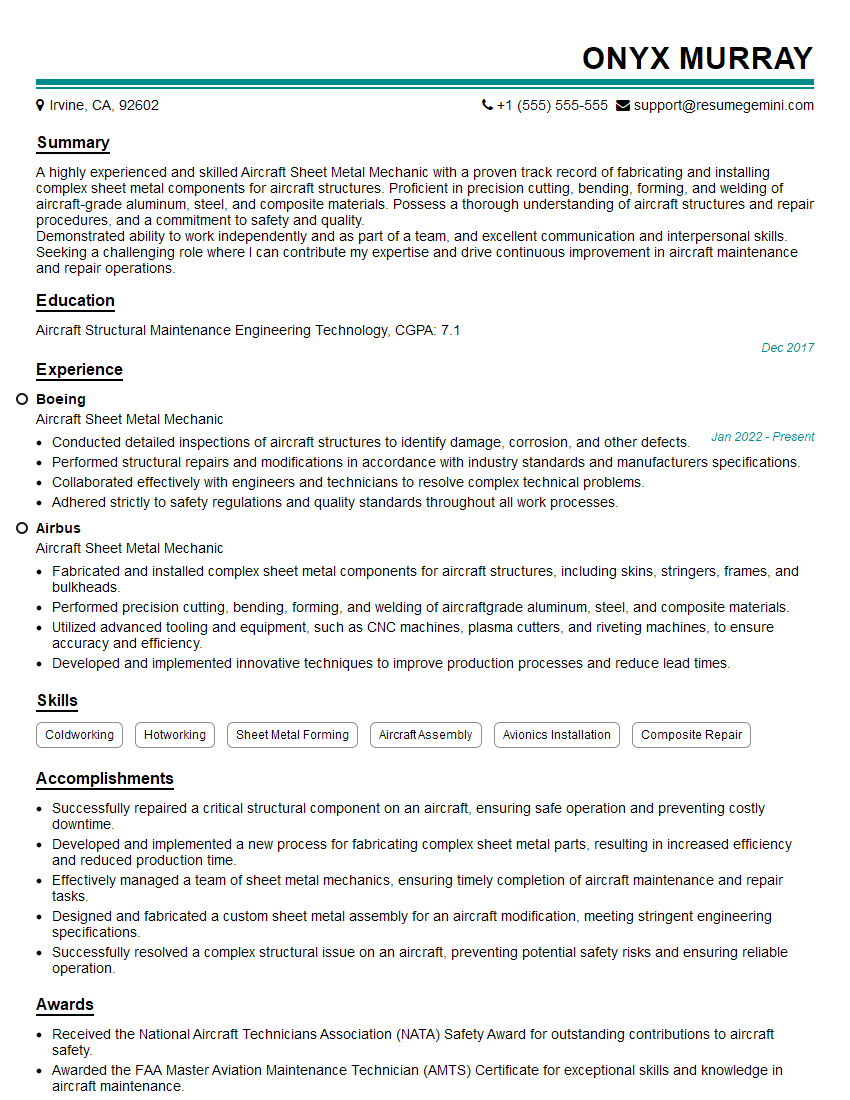

Onyx Murray

Aircraft Sheet Metal Mechanic

Summary

A highly experienced and skilled Aircraft Sheet Metal Mechanic with a proven track record of fabricating and installing complex sheet metal components for aircraft structures. Proficient in precision cutting, bending, forming, and welding of aircraft-grade aluminum, steel, and composite materials. Possess a thorough understanding of aircraft structures and repair procedures, and a commitment to safety and quality.

Demonstrated ability to work independently and as part of a team, and excellent communication and interpersonal skills. Seeking a challenging role where I can contribute my expertise and drive continuous improvement in aircraft maintenance and repair operations.

Education

Aircraft Structural Maintenance Engineering Technology

December 2017

Skills

- Coldworking

- Hotworking

- Sheet Metal Forming

- Aircraft Assembly

- Avionics Installation

- Composite Repair

Work Experience

Aircraft Sheet Metal Mechanic

- Conducted detailed inspections of aircraft structures to identify damage, corrosion, and other defects.

- Performed structural repairs and modifications in accordance with industry standards and manufacturers specifications.

- Collaborated effectively with engineers and technicians to resolve complex technical problems.

- Adhered strictly to safety regulations and quality standards throughout all work processes.

Aircraft Sheet Metal Mechanic

- Fabricated and installed complex sheet metal components for aircraft structures, including skins, stringers, frames, and bulkheads.

- Performed precision cutting, bending, forming, and welding of aircraftgrade aluminum, steel, and composite materials.

- Utilized advanced tooling and equipment, such as CNC machines, plasma cutters, and riveting machines, to ensure accuracy and efficiency.

- Developed and implemented innovative techniques to improve production processes and reduce lead times.

Accomplishments

- Successfully repaired a critical structural component on an aircraft, ensuring safe operation and preventing costly downtime.

- Developed and implemented a new process for fabricating complex sheet metal parts, resulting in increased efficiency and reduced production time.

- Effectively managed a team of sheet metal mechanics, ensuring timely completion of aircraft maintenance and repair tasks.

- Designed and fabricated a custom sheet metal assembly for an aircraft modification, meeting stringent engineering specifications.

- Successfully resolved a complex structural issue on an aircraft, preventing potential safety risks and ensuring reliable operation.

Awards

- Received the National Aircraft Technicians Association (NATA) Safety Award for outstanding contributions to aircraft safety.

- Awarded the FAA Master Aviation Maintenance Technician (AMTS) Certificate for exceptional skills and knowledge in aircraft maintenance.

- Honored with the Aviation Week Networks 40 Under 40 Award for outstanding leadership and innovation in the aviation industry.

- Recognized with the Boeing Aircraft Safety Award for contributions to improving safety standards and practices.

Certificates

- FAA Part 145 Repairman Certificate

- IATA Dangerous Goods Certification

- AS9100 and ISO 9001 Certification

- EASA Part 145 Repairman License

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Sheet Metal Mechanic

- Highlight your relevant skills and experience in your resume, such as your proficiency in coldworking, hotworking, sheet metal forming, aircraft assembly, avionics installation, and composite repair.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work. For example, you could mention that you reduced lead times by a certain percentage or improved production efficiency by a specific amount.

- Proofread your resume carefully for any errors in grammar or spelling. A well-written resume will make a good impression on potential employers.

- Tailor your resume to each job you apply for. Highlight the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Aircraft Sheet Metal Mechanic Resume

- Fabricate and install sheet metal components for aircraft structures, including skins, stringers, frames, and bulkheads.

- Perform precision cutting, bending, forming, and welding of aircraft-grade aluminum, steel, and composite materials.

- Utilize advanced tooling and equipment, such as CNC machines, plasma cutters, and riveting machines, to ensure accuracy and efficiency.

- Conduct detailed inspections of aircraft structures to identify damage, corrosion, and other defects.

- Perform structural repairs and modifications in accordance with industry standards and manufacturers specifications.

- Develop and implement innovative techniques to improve production processes and reduce lead times.

Frequently Asked Questions (FAQ’s) For Aircraft Sheet Metal Mechanic

What is the role of an Aircraft Sheet Metal Mechanic?

Aircraft Sheet Metal Mechanics fabricate and install sheet metal components for aircraft structures, including skins, stringers, frames, and bulkheads. They perform precision cutting, bending, forming, and welding of aircraft-grade aluminum, steel, and composite materials. Aircraft Sheet Metal Mechanics also conduct detailed inspections of aircraft structures to identify damage, corrosion, and other defects, and perform structural repairs and modifications in accordance with industry standards and manufacturers specifications.

What are the educational requirements for becoming an Aircraft Sheet Metal Mechanic?

Most Aircraft Sheet Metal Mechanics have a high school diploma or equivalent. Some employers may require applicants to have an associate’s degree in aircraft structural maintenance engineering technology or a related field.

What are the job prospects for Aircraft Sheet Metal Mechanics?

The job outlook for Aircraft Sheet Metal Mechanics is expected to be good over the next few years. The increasing demand for air travel is expected to lead to a growing need for qualified mechanics to maintain and repair aircraft.

What are the key skills for Aircraft Sheet Metal Mechanics?

Aircraft Sheet Metal Mechanics should have strong skills in coldworking, hotworking, sheet metal forming, aircraft assembly, avionics installation, and composite repair. They should also be proficient in the use of advanced tooling and equipment, such as CNC machines, plasma cutters, and riveting machines.

What are the salary expectations for Aircraft Sheet Metal Mechanics?

The salary for Aircraft Sheet Metal Mechanics can vary depending on their experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Aircraft Sheet Metal Mechanics was $64,820 in May 2021.

What are the career advancement opportunities for Aircraft Sheet Metal Mechanics?

Aircraft Sheet Metal Mechanics can advance their careers by becoming supervisors, quality control inspectors, or engineers. They may also choose to specialize in a particular area of aircraft maintenance, such as avionics or composite repair.