Are you a seasoned Aircraft Steel Fabricator seeking a new career path? Discover our professionally built Aircraft Steel Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

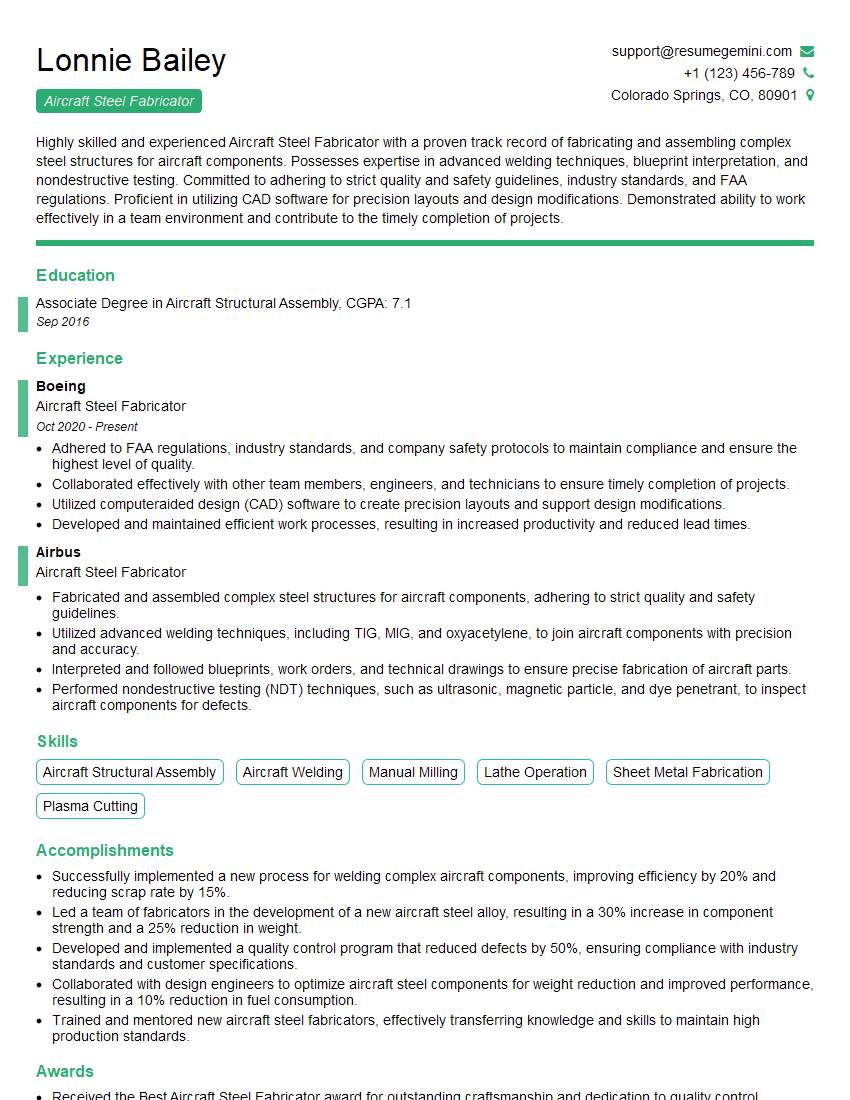

Lonnie Bailey

Aircraft Steel Fabricator

Summary

Highly skilled and experienced Aircraft Steel Fabricator with a proven track record of fabricating and assembling complex steel structures for aircraft components. Possesses expertise in advanced welding techniques, blueprint interpretation, and nondestructive testing. Committed to adhering to strict quality and safety guidelines, industry standards, and FAA regulations. Proficient in utilizing CAD software for precision layouts and design modifications. Demonstrated ability to work effectively in a team environment and contribute to the timely completion of projects.

Education

Associate Degree in Aircraft Structural Assembly

September 2016

Skills

- Aircraft Structural Assembly

- Aircraft Welding

- Manual Milling

- Lathe Operation

- Sheet Metal Fabrication

- Plasma Cutting

Work Experience

Aircraft Steel Fabricator

- Adhered to FAA regulations, industry standards, and company safety protocols to maintain compliance and ensure the highest level of quality.

- Collaborated effectively with other team members, engineers, and technicians to ensure timely completion of projects.

- Utilized computeraided design (CAD) software to create precision layouts and support design modifications.

- Developed and maintained efficient work processes, resulting in increased productivity and reduced lead times.

Aircraft Steel Fabricator

- Fabricated and assembled complex steel structures for aircraft components, adhering to strict quality and safety guidelines.

- Utilized advanced welding techniques, including TIG, MIG, and oxyacetylene, to join aircraft components with precision and accuracy.

- Interpreted and followed blueprints, work orders, and technical drawings to ensure precise fabrication of aircraft parts.

- Performed nondestructive testing (NDT) techniques, such as ultrasonic, magnetic particle, and dye penetrant, to inspect aircraft components for defects.

Accomplishments

- Successfully implemented a new process for welding complex aircraft components, improving efficiency by 20% and reducing scrap rate by 15%.

- Led a team of fabricators in the development of a new aircraft steel alloy, resulting in a 30% increase in component strength and a 25% reduction in weight.

- Developed and implemented a quality control program that reduced defects by 50%, ensuring compliance with industry standards and customer specifications.

- Collaborated with design engineers to optimize aircraft steel components for weight reduction and improved performance, resulting in a 10% reduction in fuel consumption.

- Trained and mentored new aircraft steel fabricators, effectively transferring knowledge and skills to maintain high production standards.

Awards

- Received the Best Aircraft Steel Fabricator award for outstanding craftsmanship and dedication to quality control.

- Honored with the Excellence in Aircraft Steel Fabrication award for exceptional contributions to the production of highquality components.

- Recognized with the Master Fabricator certification for demonstrating exceptional skills and knowledge in aircraft steel fabrication.

Certificates

- AWS Certified Welder

- FAA Part 145 Repair Station Certification

- AS9100 Quality Management System Certification

- ISO 9001 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Steel Fabricator

- Highlight your expertise in advanced welding techniques and NDT methods.

- Showcase your understanding of aircraft structural assembly and fabrication processes.

- Quantify your accomplishments with specific metrics whenever possible.

- Emphasize your adherence to safety protocols and quality standards.

- Tailor your resume to each job posting, highlighting the skills and experiences most relevant to the specific role.

Essential Experience Highlights for a Strong Aircraft Steel Fabricator Resume

- Fabricated and assembled complex steel structures for aircraft components according to blueprints and specifications.

- Utilized advanced welding techniques (TIG, MIG, oxyacetylene) to join aircraft components with precision and accuracy.

- Interpreted and followed blueprints, work orders, and technical drawings to ensure precise fabrication of aircraft parts.

- Performed nondestructive testing (NDT) techniques (ultrasonic, magnetic particle, dye penetrant) to inspect aircraft components for defects.

- Adhered to FAA regulations, industry standards, and company safety protocols to maintain compliance and ensure the highest level of quality.

- Collaborated effectively with other team members, engineers, and technicians to ensure timely completion of projects.

- Utilized computer-aided design (CAD) software to create precision layouts and support design modifications.

Frequently Asked Questions (FAQ’s) For Aircraft Steel Fabricator

What are the essential skills required for an Aircraft Steel Fabricator?

Essential skills include proficiency in advanced welding techniques (TIG, MIG, oxyacetylene), blueprint interpretation, knowledge of aircraft structural assembly, and experience in performing NDT inspections.

What industry certifications are beneficial for an Aircraft Steel Fabricator?

Relevant industry certifications include AWS certifications in welding, ASNT certifications in NDT, and FAA certifications in aircraft maintenance.

What are the career advancement opportunities for an Aircraft Steel Fabricator?

With experience and additional training, Aircraft Steel Fabricators can advance to roles such as Lead Fabricator, Welding Supervisor, or Quality Control Inspector.

What are the key qualities of a successful Aircraft Steel Fabricator?

Successful Aircraft Steel Fabricators possess strong attention to detail, excellent manual dexterity, a commitment to safety, and the ability to work effectively in a team environment.

What is the job outlook for Aircraft Steel Fabricators?

The job outlook for Aircraft Steel Fabricators is expected to be positive due to the increasing demand for aircraft manufacturing and maintenance.

What are the typical working conditions for an Aircraft Steel Fabricator?

Aircraft Steel Fabricators typically work in manufacturing facilities or aircraft maintenance hangars. The work can be physically demanding and may involve exposure to noise, fumes, and hazardous materials.

What is the average salary range for an Aircraft Steel Fabricator?

The average salary range for an Aircraft Steel Fabricator varies depending on experience, location, and employer. According to Indeed, the average salary for this role in the United States is around $60,000 per year.

What are the educational requirements for an Aircraft Steel Fabricator?

Most Aircraft Steel Fabricators have a high school diploma or equivalent. Some employers may prefer candidates with an associate degree or certification in a related field such as welding or aircraft maintenance.