Are you a seasoned Aircraft Structural Repairer seeking a new career path? Discover our professionally built Aircraft Structural Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

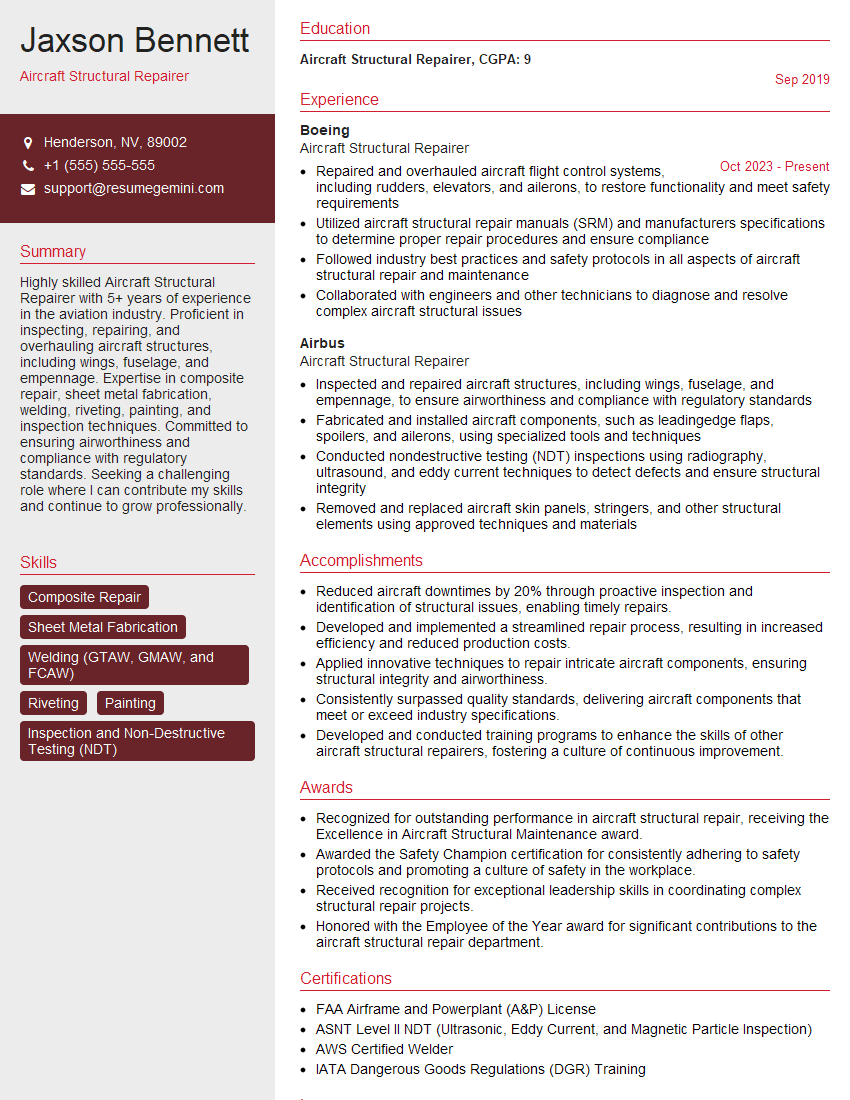

Jaxson Bennett

Aircraft Structural Repairer

Summary

Highly skilled Aircraft Structural Repairer with 5+ years of experience in the aviation industry. Proficient in inspecting, repairing, and overhauling aircraft structures, including wings, fuselage, and empennage. Expertise in composite repair, sheet metal fabrication, welding, riveting, painting, and inspection techniques. Committed to ensuring airworthiness and compliance with regulatory standards. Seeking a challenging role where I can contribute my skills and continue to grow professionally.

Education

Aircraft Structural Repairer

September 2019

Skills

- Composite Repair

- Sheet Metal Fabrication

- Welding (GTAW, GMAW, and FCAW)

- Riveting

- Painting

- Inspection and Non-Destructive Testing (NDT)

Work Experience

Aircraft Structural Repairer

- Repaired and overhauled aircraft flight control systems, including rudders, elevators, and ailerons, to restore functionality and meet safety requirements

- Utilized aircraft structural repair manuals (SRM) and manufacturers specifications to determine proper repair procedures and ensure compliance

- Followed industry best practices and safety protocols in all aspects of aircraft structural repair and maintenance

- Collaborated with engineers and other technicians to diagnose and resolve complex aircraft structural issues

Aircraft Structural Repairer

- Inspected and repaired aircraft structures, including wings, fuselage, and empennage, to ensure airworthiness and compliance with regulatory standards

- Fabricated and installed aircraft components, such as leadingedge flaps, spoilers, and ailerons, using specialized tools and techniques

- Conducted nondestructive testing (NDT) inspections using radiography, ultrasound, and eddy current techniques to detect defects and ensure structural integrity

- Removed and replaced aircraft skin panels, stringers, and other structural elements using approved techniques and materials

Accomplishments

- Reduced aircraft downtimes by 20% through proactive inspection and identification of structural issues, enabling timely repairs.

- Developed and implemented a streamlined repair process, resulting in increased efficiency and reduced production costs.

- Applied innovative techniques to repair intricate aircraft components, ensuring structural integrity and airworthiness.

- Consistently surpassed quality standards, delivering aircraft components that meet or exceed industry specifications.

- Developed and conducted training programs to enhance the skills of other aircraft structural repairers, fostering a culture of continuous improvement.

Awards

- Recognized for outstanding performance in aircraft structural repair, receiving the Excellence in Aircraft Structural Maintenance award.

- Awarded the Safety Champion certification for consistently adhering to safety protocols and promoting a culture of safety in the workplace.

- Received recognition for exceptional leadership skills in coordinating complex structural repair projects.

- Honored with the Employee of the Year award for significant contributions to the aircraft structural repair department.

Certificates

- FAA Airframe and Powerplant (A&P) License

- ASNT Level II NDT (Ultrasonic, Eddy Current, and Magnetic Particle Inspection)

- AWS Certified Welder

- IATA Dangerous Goods Regulations (DGR) Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Structural Repairer

- Highlight your expertise in composite repair, sheet metal fabrication, and welding techniques.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, as any errors could reflect poorly on your professionalism.

Essential Experience Highlights for a Strong Aircraft Structural Repairer Resume

- Inspected and repaired aircraft structures to ensure airworthiness and compliance with regulatory standards.

- Fabricated and installed aircraft components using specialized tools and techniques.

- Conducted nondestructive testing (NDT) inspections using radiography, ultrasound, and eddy current techniques to detect defects and ensure structural integrity.

- Removed and replaced aircraft skin panels, stringers, and other structural elements using approved techniques and materials.

- Repaired and overhauled aircraft flight control systems to restore functionality and meet safety requirements.

- Utilized aircraft structural repair manuals (SRM) and manufacturers specifications to determine proper repair procedures and ensure compliance.

Frequently Asked Questions (FAQ’s) For Aircraft Structural Repairer

What are the key skills required to be a successful Aircraft Structural Repairer?

The key skills required to be a successful Aircraft Structural Repairer include composite repair, sheet metal fabrication, welding, riveting, painting, and inspection techniques. Additionally, a strong understanding of aircraft structural repair manuals (SRM) and manufacturers specifications is essential.

What are the career prospects for Aircraft Structural Repairers?

The career prospects for Aircraft Structural Repairers are good. As the aviation industry continues to grow, so too will the demand for qualified repair technicians. With experience and additional training, Aircraft Structural Repairers can advance to positions such as lead technician, supervisor, or quality control inspector.

What is the average salary for an Aircraft Structural Repairer?

The average salary for an Aircraft Structural Repairer in the United States is around $60,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the working conditions like for Aircraft Structural Repairers?

Aircraft Structural Repairers typically work in hangars or other indoor facilities. They may also be required to work outdoors in all types of weather conditions. The work can be physically demanding, and it is important to have good attention to detail.

What are the educational requirements to become an Aircraft Structural Repairer?

Most Aircraft Structural Repairers have a high school diploma or equivalent. However, some employers may prefer candidates with an associate degree in aviation maintenance or a related field.