Are you a seasoned Aircraft Structures and Surfaces Assembler seeking a new career path? Discover our professionally built Aircraft Structures and Surfaces Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

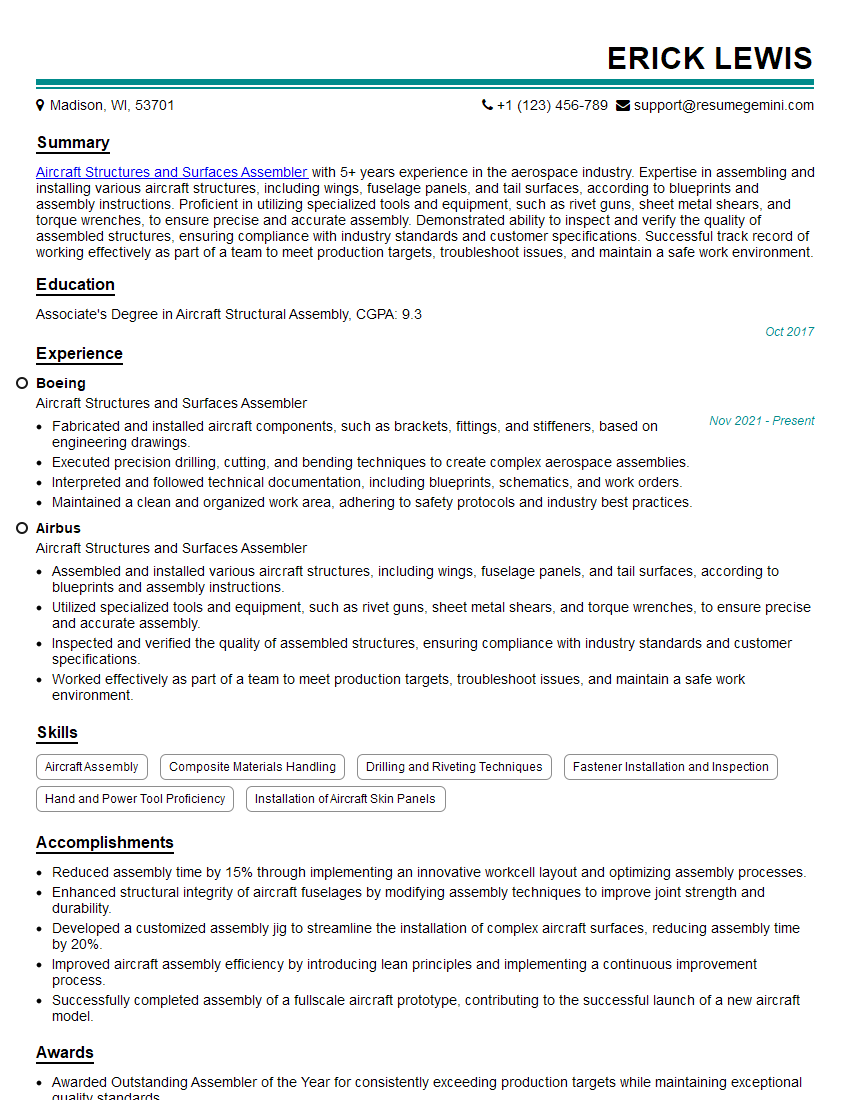

Erick Lewis

Aircraft Structures and Surfaces Assembler

Summary

Aircraft Structures and Surfaces Assembler with 5+ years experience in the aerospace industry. Expertise in assembling and installing various aircraft structures, including wings, fuselage panels, and tail surfaces, according to blueprints and assembly instructions. Proficient in utilizing specialized tools and equipment, such as rivet guns, sheet metal shears, and torque wrenches, to ensure precise and accurate assembly. Demonstrated ability to inspect and verify the quality of assembled structures, ensuring compliance with industry standards and customer specifications. Successful track record of working effectively as part of a team to meet production targets, troubleshoot issues, and maintain a safe work environment.

Education

Associate’s Degree in Aircraft Structural Assembly

October 2017

Skills

- Aircraft Assembly

- Composite Materials Handling

- Drilling and Riveting Techniques

- Fastener Installation and Inspection

- Hand and Power Tool Proficiency

- Installation of Aircraft Skin Panels

Work Experience

Aircraft Structures and Surfaces Assembler

- Fabricated and installed aircraft components, such as brackets, fittings, and stiffeners, based on engineering drawings.

- Executed precision drilling, cutting, and bending techniques to create complex aerospace assemblies.

- Interpreted and followed technical documentation, including blueprints, schematics, and work orders.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

Aircraft Structures and Surfaces Assembler

- Assembled and installed various aircraft structures, including wings, fuselage panels, and tail surfaces, according to blueprints and assembly instructions.

- Utilized specialized tools and equipment, such as rivet guns, sheet metal shears, and torque wrenches, to ensure precise and accurate assembly.

- Inspected and verified the quality of assembled structures, ensuring compliance with industry standards and customer specifications.

- Worked effectively as part of a team to meet production targets, troubleshoot issues, and maintain a safe work environment.

Accomplishments

- Reduced assembly time by 15% through implementing an innovative workcell layout and optimizing assembly processes.

- Enhanced structural integrity of aircraft fuselages by modifying assembly techniques to improve joint strength and durability.

- Developed a customized assembly jig to streamline the installation of complex aircraft surfaces, reducing assembly time by 20%.

- Improved aircraft assembly efficiency by introducing lean principles and implementing a continuous improvement process.

- Successfully completed assembly of a fullscale aircraft prototype, contributing to the successful launch of a new aircraft model.

Awards

- Awarded Outstanding Assembler of the Year for consistently exceeding production targets while maintaining exceptional quality standards.

- Recognized for Excellence in Aircraft Structure Assembly for consistently delivering highquality aircraft components that meet stringent industry specifications.

- Honored with the Safety Champion Award for spearheading safety initiatives that significantly reduced workplace hazards and improved overall safety compliance.

- Consistently exceeded performance benchmarks by assembling aircraft structures with zero defects and in record time.

Certificates

- Airframe and Powerplant (A&P) License

- Aircraft Structures Repair Technician (ASRT)

- Certified Aircraft Draftsman (CAD)

- Certified Composites Manufacturing Technologist (CCMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Structures and Surfaces Assembler

- Highlight your skills and experience in assembling and installing aircraft structures, using specialized tools and equipment.

- Emphasize your ability to work effectively as part of a team and meet production targets.

- Include any certifications or training you have received in aircraft assembly.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Aircraft Structures and Surfaces Assembler Resume

- Assembled and installed various aircraft structures, including wings, fuselage panels, and tail surfaces, according to blueprints and assembly instructions.

- Utilized specialized tools and equipment, such as rivet guns, sheet metal shears, and torque wrenches, to ensure precise and accurate assembly.

- Inspected and verified the quality of assembled structures, ensuring compliance with industry standards and customer specifications.

- Worked effectively as part of a team to meet production targets, troubleshoot issues, and maintain a safe work environment.

- Fabricated and installed aircraft components, such as brackets, fittings, and stiffeners, based on engineering drawings.

Frequently Asked Questions (FAQ’s) For Aircraft Structures and Surfaces Assembler

What is the role of an Aircraft Structures and Surfaces Assembler?

Aircraft Structures and Surfaces Assemblers assemble and install various aircraft structures, including wings, fuselage panels, and tail surfaces. They use specialized tools and equipment to ensure precise and accurate assembly, and they inspect and verify the quality of assembled structures to ensure compliance with industry standards and customer specifications.

What skills are required to be an Aircraft Structures and Surfaces Assembler?

Aircraft Structures and Surfaces Assemblers typically need to have the following skills: experience in assembling and installing aircraft structures, proficiency in using specialized tools and equipment, ability to work effectively as part of a team, ability to meet production targets, and ability to inspect and verify the quality of assembled structures.

What is the work environment like for an Aircraft Structures and Surfaces Assembler?

Aircraft Structures and Surfaces Assemblers typically work in a manufacturing environment. They may work in a team or individually, and they may work on a variety of aircraft structures. The work can be physically demanding, and it requires attention to detail and precision.

What is the career outlook for an Aircraft Structures and Surfaces Assembler?

The career outlook for Aircraft Structures and Surfaces Assemblers is expected to be good. The aerospace industry is growing, and there is a demand for qualified workers. Aircraft Structures and Surfaces Assemblers with the right skills and experience can find employment in a variety of settings, including aircraft manufacturing companies, airlines, and government agencies.

What are the earning expectations for an Aircraft Structures and Surfaces Assembler?

The earning expectations for Aircraft Structures and Surfaces Assemblers vary depending on their experience, skills, and location. However, the median annual salary for Aircraft Structures and Surfaces Assemblers is around $60,000.