Are you a seasoned Alodize Machine Operator seeking a new career path? Discover our professionally built Alodize Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

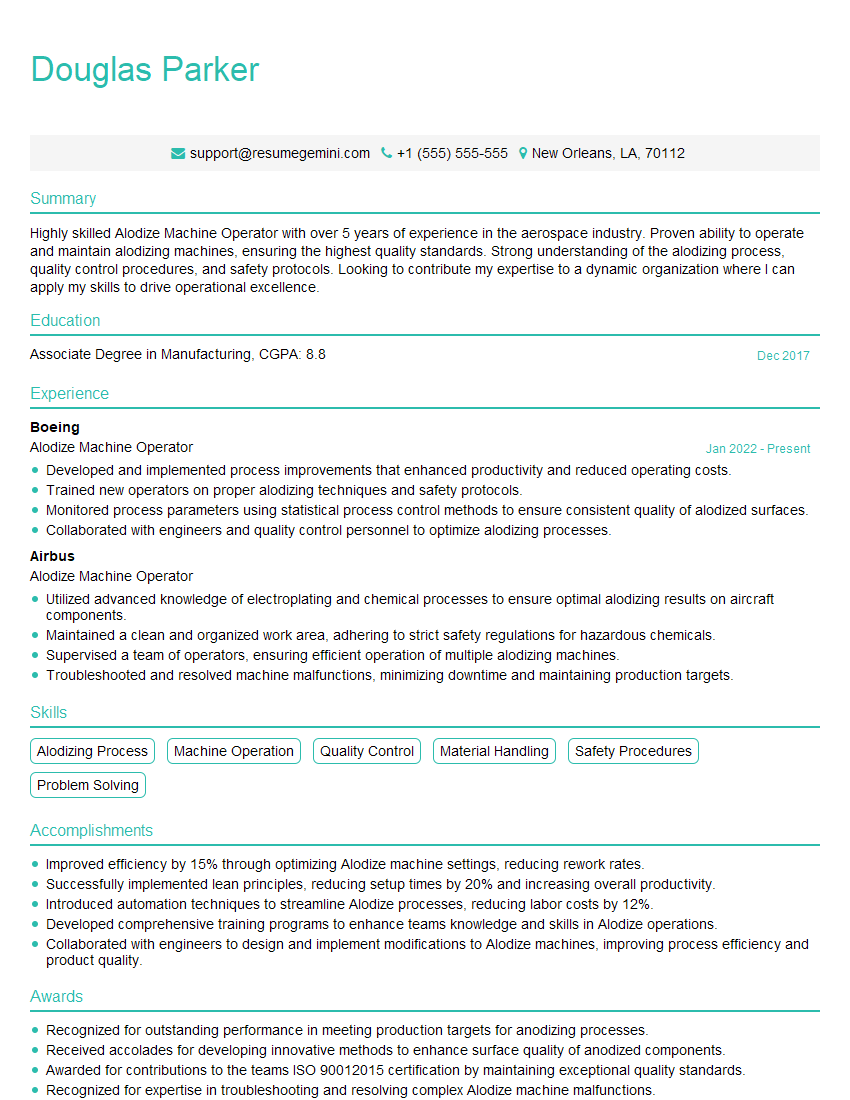

Douglas Parker

Alodize Machine Operator

Summary

Highly skilled Alodize Machine Operator with over 5 years of experience in the aerospace industry. Proven ability to operate and maintain alodizing machines, ensuring the highest quality standards. Strong understanding of the alodizing process, quality control procedures, and safety protocols. Looking to contribute my expertise to a dynamic organization where I can apply my skills to drive operational excellence.

Education

Associate Degree in Manufacturing

December 2017

Skills

- Alodizing Process

- Machine Operation

- Quality Control

- Material Handling

- Safety Procedures

- Problem Solving

Work Experience

Alodize Machine Operator

- Developed and implemented process improvements that enhanced productivity and reduced operating costs.

- Trained new operators on proper alodizing techniques and safety protocols.

- Monitored process parameters using statistical process control methods to ensure consistent quality of alodized surfaces.

- Collaborated with engineers and quality control personnel to optimize alodizing processes.

Alodize Machine Operator

- Utilized advanced knowledge of electroplating and chemical processes to ensure optimal alodizing results on aircraft components.

- Maintained a clean and organized work area, adhering to strict safety regulations for hazardous chemicals.

- Supervised a team of operators, ensuring efficient operation of multiple alodizing machines.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and maintaining production targets.

Accomplishments

- Improved efficiency by 15% through optimizing Alodize machine settings, reducing rework rates.

- Successfully implemented lean principles, reducing setup times by 20% and increasing overall productivity.

- Introduced automation techniques to streamline Alodize processes, reducing labor costs by 12%.

- Developed comprehensive training programs to enhance teams knowledge and skills in Alodize operations.

- Collaborated with engineers to design and implement modifications to Alodize machines, improving process efficiency and product quality.

Awards

- Recognized for outstanding performance in meeting production targets for anodizing processes.

- Received accolades for developing innovative methods to enhance surface quality of anodized components.

- Awarded for contributions to the teams ISO 90012015 certification by maintaining exceptional quality standards.

- Recognized for expertise in troubleshooting and resolving complex Alodize machine malfunctions.

Certificates

- OSHA Hazardous Waste Management

- CPR and First Aid

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Alodize Machine Operator

- Highlight your experience in operating and maintaining alodizing machines, emphasizing your ability to achieve high-quality results.

- Demonstrate your understanding of the alodizing process and your adherence to quality control procedures.

- Showcase your problem-solving skills and ability to resolve operational issues promptly.

- Emphasize your commitment to safety and your familiarity with industry-standard protocols.

Essential Experience Highlights for a Strong Alodize Machine Operator Resume

- Operated and maintained alodizing machines, ensuring smooth production flow and adherence to quality standards.

- Monitored and controlled process parameters, including temperature, chemical concentrations, and dwell times, to achieve optimal results.

- Conducted regular inspections of finished parts to ensure compliance with specifications and customer requirements.

- Identified and resolved operational issues promptly, minimizing downtime and maintaining production efficiency.

- Followed established safety protocols, including proper handling of chemicals and equipment, to ensure a safe work environment.

- Collaborated with production teams to optimize processes and improve overall productivity.

Frequently Asked Questions (FAQ’s) For Alodize Machine Operator

What is the role of an Alodize Machine Operator?

An Alodize Machine Operator is responsible for operating and maintaining alodizing machines, ensuring the proper surface treatment of metal parts. They play a crucial role in the manufacturing process, contributing to the corrosion resistance and durability of finished products.

What are the key skills required for an Alodize Machine Operator?

Essential skills for an Alodize Machine Operator include proficiency in operating alodizing machines, understanding of the alodizing process, quality control procedures, material handling, safety protocols, and problem-solving abilities.

What industries employ Alodize Machine Operators?

Alodize Machine Operators are primarily employed in the manufacturing sector, particularly in industries such as aerospace, automotive, and electronics, where the surface treatment of metal components is crucial for performance and durability.

What is the typical education and experience required for an Alodize Machine Operator?

While formal education requirements may vary, many Alodize Machine Operators hold an associate’s degree in manufacturing or a related field. Additionally, prior experience in operating production machinery and a strong understanding of quality control principles are often sought by employers.

What are the career growth opportunities for an Alodize Machine Operator?

Experienced Alodize Machine Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Manager. With further education and specialized training, they may also pursue career paths in engineering or process development.

What is the job outlook for Alodize Machine Operators?

The job outlook for Alodize Machine Operators is expected to remain stable in the coming years. The manufacturing sector continues to rely on skilled operators to ensure the quality and efficiency of production processes, particularly in industries where metal surface treatment is critical.

What are the safety precautions that Alodize Machine Operators must follow?

Alodize Machine Operators must adhere to strict safety protocols, including wearing appropriate protective gear, handling chemicals safely, following lockout/tagout procedures, and maintaining a clean and organized work area. They must also be aware of potential hazards associated with the alodizing process, such as chemical spills and exposure to fumes.

What are the key quality control measures that Alodize Machine Operators implement?

Alodize Machine Operators play a vital role in quality control by monitoring process parameters, conducting regular inspections, and ensuring the proper application of coatings. They follow established procedures and specifications to maintain consistent quality and meet customer requirements.