Are you a seasoned Aluminum Pourer seeking a new career path? Discover our professionally built Aluminum Pourer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

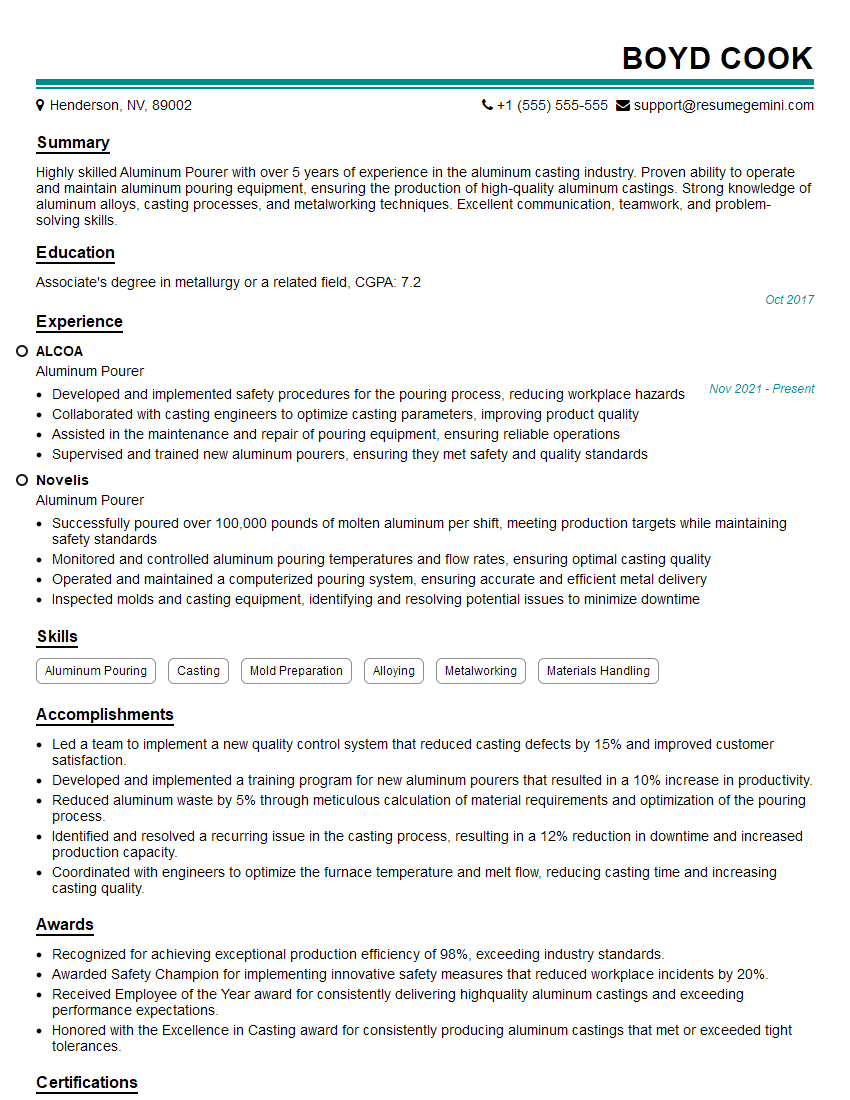

Boyd Cook

Aluminum Pourer

Summary

Highly skilled Aluminum Pourer with over 5 years of experience in the aluminum casting industry. Proven ability to operate and maintain aluminum pouring equipment, ensuring the production of high-quality aluminum castings. Strong knowledge of aluminum alloys, casting processes, and metalworking techniques. Excellent communication, teamwork, and problem-solving skills.

Education

Associate’s degree in metallurgy or a related field

October 2017

Skills

- Aluminum Pouring

- Casting

- Mold Preparation

- Alloying

- Metalworking

- Materials Handling

Work Experience

Aluminum Pourer

- Developed and implemented safety procedures for the pouring process, reducing workplace hazards

- Collaborated with casting engineers to optimize casting parameters, improving product quality

- Assisted in the maintenance and repair of pouring equipment, ensuring reliable operations

- Supervised and trained new aluminum pourers, ensuring they met safety and quality standards

Aluminum Pourer

- Successfully poured over 100,000 pounds of molten aluminum per shift, meeting production targets while maintaining safety standards

- Monitored and controlled aluminum pouring temperatures and flow rates, ensuring optimal casting quality

- Operated and maintained a computerized pouring system, ensuring accurate and efficient metal delivery

- Inspected molds and casting equipment, identifying and resolving potential issues to minimize downtime

Accomplishments

- Led a team to implement a new quality control system that reduced casting defects by 15% and improved customer satisfaction.

- Developed and implemented a training program for new aluminum pourers that resulted in a 10% increase in productivity.

- Reduced aluminum waste by 5% through meticulous calculation of material requirements and optimization of the pouring process.

- Identified and resolved a recurring issue in the casting process, resulting in a 12% reduction in downtime and increased production capacity.

- Coordinated with engineers to optimize the furnace temperature and melt flow, reducing casting time and increasing casting quality.

Awards

- Recognized for achieving exceptional production efficiency of 98%, exceeding industry standards.

- Awarded Safety Champion for implementing innovative safety measures that reduced workplace incidents by 20%.

- Received Employee of the Year award for consistently delivering highquality aluminum castings and exceeding performance expectations.

- Honored with the Excellence in Casting award for consistently producing aluminum castings that met or exceeded tight tolerances.

Certificates

- Certified Aluminum Pourer

- OSHA Safety Certification

- ISO 9001 Certification

- Aluminum Association Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aluminum Pourer

- Highlight your experience and skills in aluminum pouring and casting techniques.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Demonstrate your knowledge of aluminum alloys, casting processes, and metalworking.

- Showcase your ability to work independently and as part of a team.

- Obtain relevant certifications, such as the Certified Aluminum Pourer (CAP) from the Aluminum Association.

Essential Experience Highlights for a Strong Aluminum Pourer Resume

- Operate and maintain aluminum pouring equipment, including furnaces, ladles, and crucibles.

- Prepare and assemble molds for casting, ensuring proper alignment and fit.

- Measure and add alloying elements to molten aluminum to achieve desired chemical composition.

- Pour molten aluminum into molds, controlling the flow rate and temperature to prevent defects.

- Monitor casting process, making adjustments as needed to ensure proper solidification and cooling.

- Inspect finished castings for defects and quality.

- Maintain a clean and organized work area, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Aluminum Pourer

What are the primary duties of an Aluminum Pourer?

The primary duties of an Aluminum Pourer include operating and maintaining aluminum pouring equipment, preparing and assembling molds, measuring and adding alloying elements, pouring molten aluminum into molds, monitoring the casting process, inspecting finished castings, and maintaining a clean and organized work area.

What skills are required to be an Aluminum Pourer?

Essential skills for an Aluminum Pourer include aluminum pouring, casting, mold preparation, alloying, metalworking, materials handling, safety protocols, and teamwork.

What is the work environment of an Aluminum Pourer like?

Aluminum Pourers typically work in foundries or metalworking facilities, which can be hot, noisy, and dusty. They may also be required to work in confined spaces or with heavy equipment.

Is the Aluminum Pourer a physically demanding job?

Yes, Aluminum Pourers must be able to lift heavy equipment, stand for long periods, and work in physically demanding conditions.

What are the career prospects for Aluminum Pourers?

Aluminum Pourers with experience and specialized skills can advance to supervisory or management positions within the metalworking industry.

How much do Aluminum Pourers earn?

The salary of an Aluminum Pourer can vary depending on experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual wage for metal pourers and casters in May 2021 was $49,680.

What are the safety precautions that Aluminum Pourers must follow?

Aluminum Pourers must wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and protective clothing, and follow established safety protocols to prevent accidents and injuries.