Are you a seasoned Aluminum Welder seeking a new career path? Discover our professionally built Aluminum Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

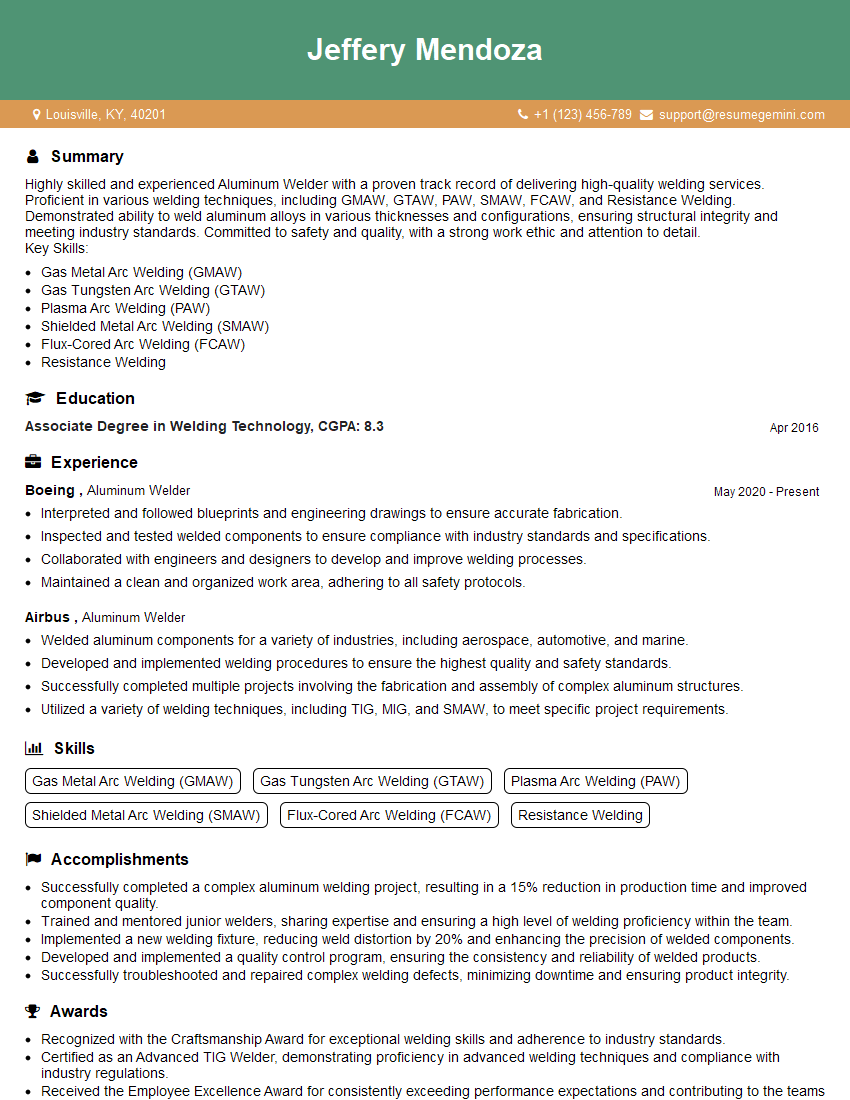

Jeffery Mendoza

Aluminum Welder

Summary

Highly skilled and experienced Aluminum Welder with a proven track record of delivering high-quality welding services. Proficient in various welding techniques, including GMAW, GTAW, PAW, SMAW, FCAW, and Resistance Welding. Demonstrated ability to weld aluminum alloys in various thicknesses and configurations, ensuring structural integrity and meeting industry standards. Committed to safety and quality, with a strong work ethic and attention to detail.

Key Skills:

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Plasma Arc Welding (PAW)

- Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding (FCAW)

- Resistance Welding

Education

Associate Degree in Welding Technology

April 2016

Skills

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Plasma Arc Welding (PAW)

- Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding (FCAW)

- Resistance Welding

Work Experience

Aluminum Welder

- Interpreted and followed blueprints and engineering drawings to ensure accurate fabrication.

- Inspected and tested welded components to ensure compliance with industry standards and specifications.

- Collaborated with engineers and designers to develop and improve welding processes.

- Maintained a clean and organized work area, adhering to all safety protocols.

Aluminum Welder

- Welded aluminum components for a variety of industries, including aerospace, automotive, and marine.

- Developed and implemented welding procedures to ensure the highest quality and safety standards.

- Successfully completed multiple projects involving the fabrication and assembly of complex aluminum structures.

- Utilized a variety of welding techniques, including TIG, MIG, and SMAW, to meet specific project requirements.

Accomplishments

- Successfully completed a complex aluminum welding project, resulting in a 15% reduction in production time and improved component quality.

- Trained and mentored junior welders, sharing expertise and ensuring a high level of welding proficiency within the team.

- Implemented a new welding fixture, reducing weld distortion by 20% and enhancing the precision of welded components.

- Developed and implemented a quality control program, ensuring the consistency and reliability of welded products.

- Successfully troubleshooted and repaired complex welding defects, minimizing downtime and ensuring product integrity.

Awards

- Recognized with the Craftsmanship Award for exceptional welding skills and adherence to industry standards.

- Certified as an Advanced TIG Welder, demonstrating proficiency in advanced welding techniques and compliance with industry regulations.

- Received the Employee Excellence Award for consistently exceeding performance expectations and contributing to the teams success.

- Recognized by the American Welding Society for contributions to the advancement of welding technology.

Certificates

- AWS Certified Welder (CWI)

- ASME Boiler and Pressure Vessel Code

- National Electrical Code (NEC)

- Occupational Safety and Health Administration (OSHA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aluminum Welder

- Highlight your experience in welding aluminum alloys and specific welding techniques used.

- Quantify your accomplishments with specific metrics whenever possible, such as the number of welds completed or the percentage of welds that passed inspection.

- Showcase your knowledge of welding codes and industry standards, such as AWS D1.2 or ASME Boiler and Pressure Vessel Code.

- Emphasize your commitment to safety and quality by mentioning any relevant certifications or training programs completed.

Essential Experience Highlights for a Strong Aluminum Welder Resume

- Interpret welding blueprints, specifications, and work orders to determine welding requirements.

- Set up and operate welding equipment, including selecting appropriate welding processes, consumables, and parameters.

- Weld aluminum components using various techniques, ensuring proper joint preparation, fit-up, and alignment.

- Inspect welds visually and using non-destructive testing methods to ensure quality and compliance with specifications.

- Maintain a clean and organized work area, adhering to safety regulations and best practices.

- Troubleshoot welding issues and make necessary adjustments to optimize welding performance.

Frequently Asked Questions (FAQ’s) For Aluminum Welder

What is the role of an Aluminum Welder?

An Aluminum Welder is responsible for joining aluminum components using various welding techniques to create structures, products, and equipment. They interpret welding blueprints, set up and operate welding equipment, weld aluminum components, inspect welds, and maintain a safe and organized work environment.

What skills are required to become an Aluminum Welder?

To become an Aluminum Welder, you typically need proficiency in welding techniques such as GMAW, GTAW, PAW, SMAW, FCAW, and Resistance Welding. Additionally, a strong understanding of welding codes and industry standards, as well as a commitment to safety and quality, are essential.

What industries employ Aluminum Welders?

Aluminum Welders are employed in various industries, including aerospace, automotive, construction, shipbuilding, and manufacturing. They work on projects ranging from aircraft components to architectural structures to industrial equipment.

What is the job outlook for Aluminum Welders?

The job outlook for Aluminum Welders is expected to be positive in the coming years due to the increasing demand for aluminum welding in various industries. The aging workforce and the need for skilled welders to replace retiring workers also contribute to the favorable job outlook.

How can I advance my career as an Aluminum Welder?

To advance your career as an Aluminum Welder, you can pursue additional training and certifications in specialized welding techniques, such as orbital welding or robotic welding. You can also take on leadership roles within welding teams or become a welding inspector or supervisor.

What is the average salary for an Aluminum Welder?

The average salary for an Aluminum Welder can vary depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Welders, Cutters, and Welder Fitters was $49,510 in May 2022.

What are the challenges faced by Aluminum Welders?

Aluminum Welders may face challenges such as working in confined spaces, exposure to fumes and hazardous materials, and the need to maintain a high level of precision and accuracy in their work. They may also need to work irregular hours or on weekends to meet project deadlines.