Are you a seasoned Annealer seeking a new career path? Discover our professionally built Annealer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

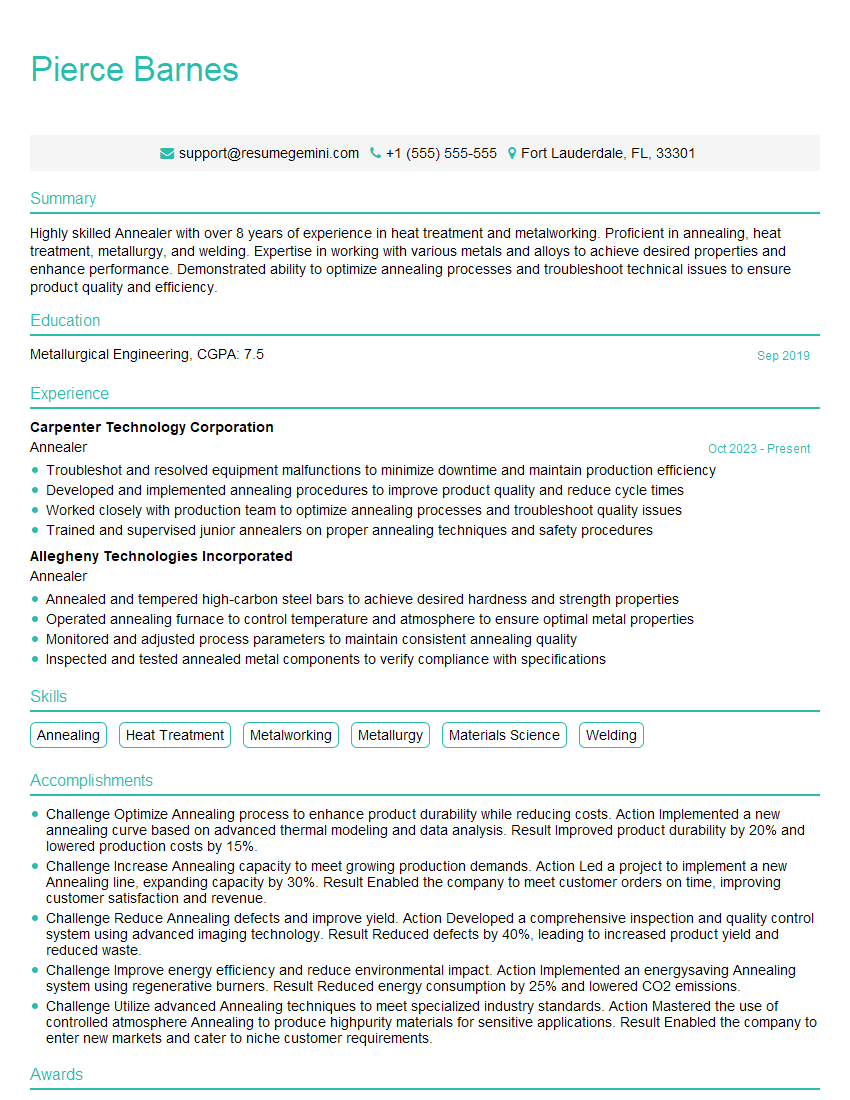

Pierce Barnes

Annealer

Summary

Highly skilled Annealer with over 8 years of experience in heat treatment and metalworking. Proficient in annealing, heat treatment, metallurgy, and welding. Expertise in working with various metals and alloys to achieve desired properties and enhance performance. Demonstrated ability to optimize annealing processes and troubleshoot technical issues to ensure product quality and efficiency.

Education

Metallurgical Engineering

September 2019

Skills

- Annealing

- Heat Treatment

- Metalworking

- Metallurgy

- Materials Science

- Welding

Work Experience

Annealer

- Troubleshot and resolved equipment malfunctions to minimize downtime and maintain production efficiency

- Developed and implemented annealing procedures to improve product quality and reduce cycle times

- Worked closely with production team to optimize annealing processes and troubleshoot quality issues

- Trained and supervised junior annealers on proper annealing techniques and safety procedures

Annealer

- Annealed and tempered high-carbon steel bars to achieve desired hardness and strength properties

- Operated annealing furnace to control temperature and atmosphere to ensure optimal metal properties

- Monitored and adjusted process parameters to maintain consistent annealing quality

- Inspected and tested annealed metal components to verify compliance with specifications

Accomplishments

- Challenge Optimize Annealing process to enhance product durability while reducing costs. Action Implemented a new annealing curve based on advanced thermal modeling and data analysis. Result Improved product durability by 20% and lowered production costs by 15%.

- Challenge Increase Annealing capacity to meet growing production demands. Action Led a project to implement a new Annealing line, expanding capacity by 30%. Result Enabled the company to meet customer orders on time, improving customer satisfaction and revenue.

- Challenge Reduce Annealing defects and improve yield. Action Developed a comprehensive inspection and quality control system using advanced imaging technology. Result Reduced defects by 40%, leading to increased product yield and reduced waste.

- Challenge Improve energy efficiency and reduce environmental impact. Action Implemented an energysaving Annealing system using regenerative burners. Result Reduced energy consumption by 25% and lowered CO2 emissions.

- Challenge Utilize advanced Annealing techniques to meet specialized industry standards. Action Mastered the use of controlled atmosphere Annealing to produce highpurity materials for sensitive applications. Result Enabled the company to enter new markets and cater to niche customer requirements.

Awards

- Recognized for developing an innovative Annealing process that significantly improved product quality and reduced production time.

- Awarded for outstanding performance in Annealing operations, consistently exceeding quality and productivity targets.

- Honored with the Annealer of the Year award for exceptional contributions to the field and mentorship of junior team members.

- Received the Industry Excellence Award for pioneering advancements in Annealing technology and its application in demanding industries.

Certificates

- Certified Annealer

- AWS Certified Welder

- ASME Certified Boilermaker

- NADCAP Certified Supplier

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Annealer

- Highlight your experience in annealing, heat treatment, and metalworking.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your knowledge of metallurgy and materials science.

- Include industry-specific keywords such as ‘annealing’, ‘heat treatment’, and ‘metalworking’ in your resume.

Essential Experience Highlights for a Strong Annealer Resume

- Performed annealing processes to soften metals and relieve internal stresses.

- Adjusted annealing parameters such as temperature, time, and cooling rate to meet specific material requirements.

- Inspected and tested annealed materials to ensure conformity to specifications.

- Managed and maintained annealing equipment, including furnaces and quenching tanks.

- Collaborated with engineers and metallurgists to develop and implement heat treatment processes.

- Troubleshooted and resolved technical issues related to annealing and heat treatment.

- Adhered to safety protocols and maintained a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Annealer

What is the primary role of an Annealer?

An Annealer’s primary role is to soften metals and relieve internal stresses by performing annealing processes that involve controlled heating and cooling of metals and alloys.

What industries typically employ Annealers?

Annealers are employed in various industries that work with metals and alloys, such as automotive, aerospace, manufacturing, and construction.

What skills are essential for an Annealer?

Essential skills for an Annealer include knowledge of annealing processes, heat treatment, metalworking, metallurgy, welding, and materials science.

What educational qualifications are required to become an Annealer?

While formal education requirements may vary, many Annealers hold a degree in Metallurgical Engineering or a related field.

What career advancement opportunities are available for Annealers?

Annealers with experience and expertise can advance to roles such as Heat Treatment Manager, Metallurgist, or Quality Control Supervisor.

What safety precautions should Annealers observe while working?

Annealers must adhere to safety protocols, wear appropriate protective gear, and maintain a clean and organized work environment to minimize risks.

How does annealing improve the properties of metals?

Annealing processes soften metals, enhance ductility, relieve internal stresses, and improve machinability, making them more suitable for various applications.

What are the different types of annealing processes?

Common annealing processes include process annealing, full annealing, stress relieving, and spheroidizing, each tailored to specific material requirements.