Are you a seasoned Annealing Furnace Tender seeking a new career path? Discover our professionally built Annealing Furnace Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

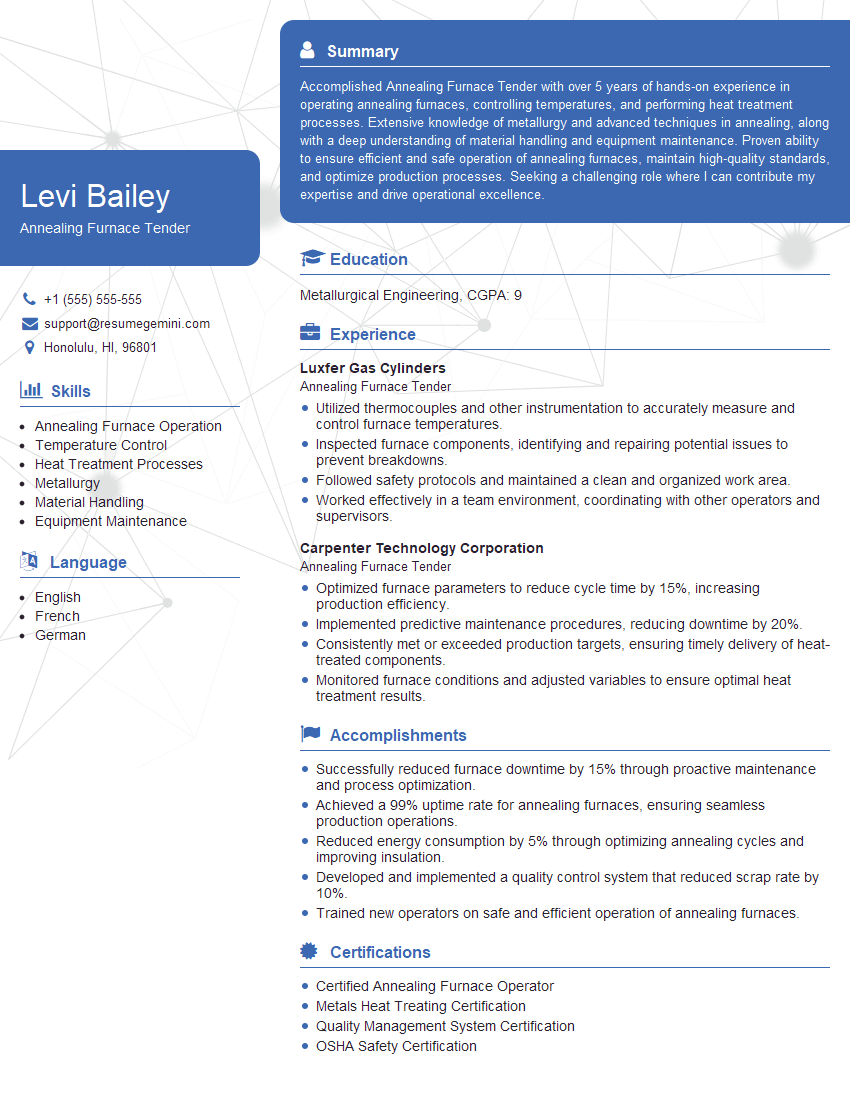

Levi Bailey

Annealing Furnace Tender

Summary

Accomplished Annealing Furnace Tender with over 5 years of hands-on experience in operating annealing furnaces, controlling temperatures, and performing heat treatment processes. Extensive knowledge of metallurgy and advanced techniques in annealing, along with a deep understanding of material handling and equipment maintenance. Proven ability to ensure efficient and safe operation of annealing furnaces, maintain high-quality standards, and optimize production processes. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Metallurgical Engineering

December 2018

Skills

- Annealing Furnace Operation

- Temperature Control

- Heat Treatment Processes

- Metallurgy

- Material Handling

- Equipment Maintenance

Work Experience

Annealing Furnace Tender

- Utilized thermocouples and other instrumentation to accurately measure and control furnace temperatures.

- Inspected furnace components, identifying and repairing potential issues to prevent breakdowns.

- Followed safety protocols and maintained a clean and organized work area.

- Worked effectively in a team environment, coordinating with other operators and supervisors.

Annealing Furnace Tender

- Optimized furnace parameters to reduce cycle time by 15%, increasing production efficiency.

- Implemented predictive maintenance procedures, reducing downtime by 20%.

- Consistently met or exceeded production targets, ensuring timely delivery of heat-treated components.

- Monitored furnace conditions and adjusted variables to ensure optimal heat treatment results.

Accomplishments

- Successfully reduced furnace downtime by 15% through proactive maintenance and process optimization.

- Achieved a 99% uptime rate for annealing furnaces, ensuring seamless production operations.

- Reduced energy consumption by 5% through optimizing annealing cycles and improving insulation.

- Developed and implemented a quality control system that reduced scrap rate by 10%.

- Trained new operators on safe and efficient operation of annealing furnaces.

Certificates

- Certified Annealing Furnace Operator

- Metals Heat Treating Certification

- Quality Management System Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Annealing Furnace Tender

Highlight your technical skills

in annealing furnace operation, temperature control, and metallurgy. Quantify your accomplishments with specific metrics whenever possible.Demonstrate your knowledge

of heat treatment processes and the effects of different annealing parameters on material properties.Showcase your ability

to manage multiple tasks and responsibilities in a fast-paced manufacturing environment.Emphasize your attention to detail

and commitment to quality control and safety.Tailor your resume

to the specific requirements of each job you apply for, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Annealing Furnace Tender Resume

- Operate and monitor annealing furnaces to heat treat metals and alloys according to specified temperatures and time cycles.

- Control and calibrate furnace temperatures using thermocouples, controllers, and other instrumentation to ensure accurate and consistent heat treatment.

- Monitor and adjust gas flow, pressure, and atmosphere to maintain optimal annealing conditions and prevent oxidation or decarburization.

- Perform material handling tasks, including loading, unloading, and transferring materials to and from furnaces using hoists, forklifts, or other equipment.

- Inspect and maintain annealing furnaces, including burners, heating elements, and safety devices, to ensure proper operation and prevent breakdowns.

- Record and maintain detailed logs of annealing parameters, temperatures, and process times for quality control and traceability.

- Follow established safety protocols and procedures to ensure a safe and compliant work environment.

Frequently Asked Questions (FAQ’s) For Annealing Furnace Tender

What is the primary role of an Annealing Furnace Tender?

An Annealing Furnace Tender operates and maintains annealing furnaces to heat treat metals and alloys, ensuring the desired material properties and performance.

What are the key skills required for an Annealing Furnace Tender?

Essential skills include annealing furnace operation, temperature control, heat treatment processes, metallurgy, material handling, and equipment maintenance.

What is the work environment like for an Annealing Furnace Tender?

Annealing Furnace Tenders typically work in industrial manufacturing facilities, operating furnaces in production lines or heat treatment departments.

What are the career prospects for an Annealing Furnace Tender?

With experience and additional training, Annealing Furnace Tenders can advance to roles such as Heat Treating Supervisor, Process Engineer, or Quality Control Manager.

What is the salary range for an Annealing Furnace Tender?

Salaries vary based on experience, location, and industry, but typically range from $30,000 to $60,000 per year.

What safety precautions are important for Annealing Furnace Tenders?

Annealing Furnace Tenders must adhere to safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.