Are you a seasoned Anodizing Line Operator seeking a new career path? Discover our professionally built Anodizing Line Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

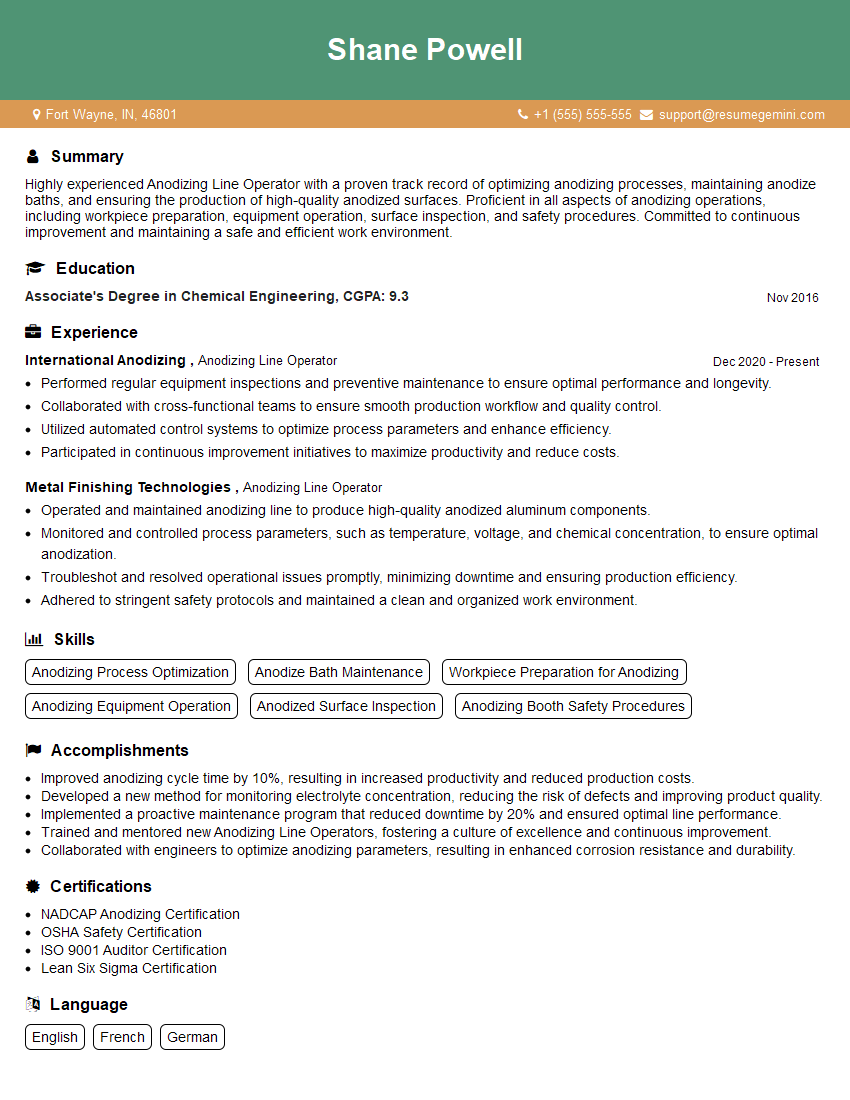

Shane Powell

Anodizing Line Operator

Summary

Highly experienced Anodizing Line Operator with a proven track record of optimizing anodizing processes, maintaining anodize baths, and ensuring the production of high-quality anodized surfaces. Proficient in all aspects of anodizing operations, including workpiece preparation, equipment operation, surface inspection, and safety procedures. Committed to continuous improvement and maintaining a safe and efficient work environment.

Education

Associate’s Degree in Chemical Engineering

November 2016

Skills

- Anodizing Process Optimization

- Anodize Bath Maintenance

- Workpiece Preparation for Anodizing

- Anodizing Equipment Operation

- Anodized Surface Inspection

- Anodizing Booth Safety Procedures

Work Experience

Anodizing Line Operator

- Performed regular equipment inspections and preventive maintenance to ensure optimal performance and longevity.

- Collaborated with cross-functional teams to ensure smooth production workflow and quality control.

- Utilized automated control systems to optimize process parameters and enhance efficiency.

- Participated in continuous improvement initiatives to maximize productivity and reduce costs.

Anodizing Line Operator

- Operated and maintained anodizing line to produce high-quality anodized aluminum components.

- Monitored and controlled process parameters, such as temperature, voltage, and chemical concentration, to ensure optimal anodization.

- Troubleshot and resolved operational issues promptly, minimizing downtime and ensuring production efficiency.

- Adhered to stringent safety protocols and maintained a clean and organized work environment.

Accomplishments

- Improved anodizing cycle time by 10%, resulting in increased productivity and reduced production costs.

- Developed a new method for monitoring electrolyte concentration, reducing the risk of defects and improving product quality.

- Implemented a proactive maintenance program that reduced downtime by 20% and ensured optimal line performance.

- Trained and mentored new Anodizing Line Operators, fostering a culture of excellence and continuous improvement.

- Collaborated with engineers to optimize anodizing parameters, resulting in enhanced corrosion resistance and durability.

Certificates

- NADCAP Anodizing Certification

- OSHA Safety Certification

- ISO 9001 Auditor Certification

- Lean Six Sigma Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Anodizing Line Operator

- Highlight your experience and expertise in anodizing process optimization.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Emphasize your commitment to maintaining a safe and compliant work environment.

- Obtain industry certifications to demonstrate your proficiency.

Essential Experience Highlights for a Strong Anodizing Line Operator Resume

- Optimized anodizing processes to improve product quality and reduce production costs.

- Maintained and calibrated anodize baths to ensure consistent and high-quality anodizing results.

- Prepared workpieces for anodizing, including cleaning, masking, and racking.

- Operated anodizing equipment safely and efficiently to achieve desired surface finishes.

- Inspected anodized surfaces to ensure compliance with specifications and customer requirements.

- Followed all anodizing booth safety procedures to maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Anodizing Line Operator

What is anodizing?

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

What are the different types of anodizing?

There are various types of anodizing, including chromic acid anodizing, sulfuric acid anodizing, and hard anodizing.

What are the benefits of anodizing?

Anodizing provides numerous benefits, including corrosion resistance, improved wear resistance, enhanced electrical insulation, and decorative finishes.

What industries use anodizing?

Anodizing has wide applications in industries such as automotive, aerospace, electronics, construction, and consumer products.

How do I become an Anodizing Line Operator?

To become an Anodizing Line Operator, you typically need an associate’s degree in chemical engineering or a related field, along with experience in anodizing processes and safety procedures.

What is the career path for an Anodizing Line Operator?

With experience and additional training, Anodizing Line Operators can advance to roles such as Anodizing Supervisor, Quality Control Inspector, or Anodizing Process Engineer.