Are you a seasoned Apprentice Instrument Technician seeking a new career path? Discover our professionally built Apprentice Instrument Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

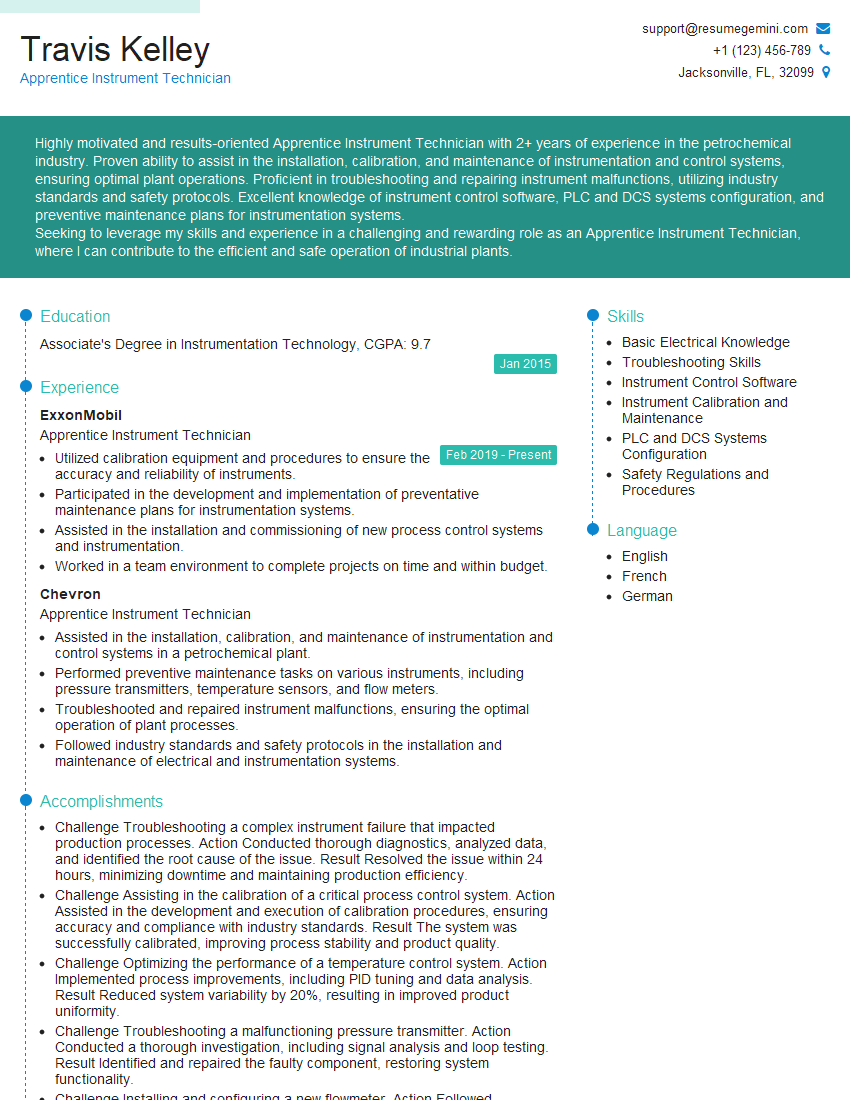

Travis Kelley

Apprentice Instrument Technician

Summary

Highly motivated and results-oriented Apprentice Instrument Technician with 2+ years of experience in the petrochemical industry. Proven ability to assist in the installation, calibration, and maintenance of instrumentation and control systems, ensuring optimal plant operations. Proficient in troubleshooting and repairing instrument malfunctions, utilizing industry standards and safety protocols. Excellent knowledge of instrument control software, PLC and DCS systems configuration, and preventive maintenance plans for instrumentation systems.

Seeking to leverage my skills and experience in a challenging and rewarding role as an Apprentice Instrument Technician, where I can contribute to the efficient and safe operation of industrial plants.

Education

Associate’s Degree in Instrumentation Technology

January 2015

Skills

- Basic Electrical Knowledge

- Troubleshooting Skills

- Instrument Control Software

- Instrument Calibration and Maintenance

- PLC and DCS Systems Configuration

- Safety Regulations and Procedures

Work Experience

Apprentice Instrument Technician

- Utilized calibration equipment and procedures to ensure the accuracy and reliability of instruments.

- Participated in the development and implementation of preventative maintenance plans for instrumentation systems.

- Assisted in the installation and commissioning of new process control systems and instrumentation.

- Worked in a team environment to complete projects on time and within budget.

Apprentice Instrument Technician

- Assisted in the installation, calibration, and maintenance of instrumentation and control systems in a petrochemical plant.

- Performed preventive maintenance tasks on various instruments, including pressure transmitters, temperature sensors, and flow meters.

- Troubleshooted and repaired instrument malfunctions, ensuring the optimal operation of plant processes.

- Followed industry standards and safety protocols in the installation and maintenance of electrical and instrumentation systems.

Accomplishments

- Challenge Troubleshooting a complex instrument failure that impacted production processes. Action Conducted thorough diagnostics, analyzed data, and identified the root cause of the issue. Result Resolved the issue within 24 hours, minimizing downtime and maintaining production efficiency.

- Challenge Assisting in the calibration of a critical process control system. Action Assisted in the development and execution of calibration procedures, ensuring accuracy and compliance with industry standards. Result The system was successfully calibrated, improving process stability and product quality.

- Challenge Optimizing the performance of a temperature control system. Action Implemented process improvements, including PID tuning and data analysis. Result Reduced system variability by 20%, resulting in improved product uniformity.

- Challenge Troubleshooting a malfunctioning pressure transmitter. Action Conducted a thorough investigation, including signal analysis and loop testing. Result Identified and repaired the faulty component, restoring system functionality.

- Challenge Installing and configuring a new flowmeter. Action Followed manufacturer specifications, ensuring proper installation and operation. Result The flowmeter was successfully installed and commissioned, providing accurate data for process control.

Awards

- Received the Apprentice of the Year Award for demonstrating exceptional skills and knowledge in instrument maintenance and troubleshooting.

- Recognized for consistently exceeding safety protocols and maintaining a clean and safe work environment.

- Received a certificate for completing a specialized training program in advanced instrumentation techniques.

- Recognized for contributing to the development of a new instrument maintenance procedure that increased efficiency by 15%.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Instrument and Automation Technician

- OSHA 30-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Apprentice Instrument Technician

Highlight your hands-on experience:

Emphasize your practical skills in installing, calibrating, and maintaining instrumentation systems.Showcase your troubleshooting abilities:

Describe your experience in diagnosing and resolving instrument malfunctions, demonstrating your problem-solving capabilities.Demonstrate your knowledge of industry standards:

Mention your adherence to safety protocols and industry best practices, showcasing your commitment to safety and compliance.Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your work, such as reducing downtime or improving instrument accuracy.Tailor your resume to the job description:

Carefully review the job posting and highlight the skills and experience that are most relevant to the role you are applying for.

Essential Experience Highlights for a Strong Apprentice Instrument Technician Resume

- Assisted in the installation, calibration, and maintenance of instrumentation and control systems in a petrochemical plant.

- Performed preventive maintenance tasks on various instruments, including pressure transmitters, temperature sensors, and flow meters.

- Troubleshooted and repaired instrument malfunctions, ensuring the optimal operation of plant processes.

- Followed industry standards and safety protocols in the installation and maintenance of electrical and instrumentation systems.

- Utilized calibration equipment and procedures to ensure the accuracy and reliability of instruments.

- Participated in the development and implementation of preventative maintenance plans for instrumentation systems.

- Assisted in the installation and commissioning of new process control systems and instrumentation.

Frequently Asked Questions (FAQ’s) For Apprentice Instrument Technician

What are the key skills required for an Apprentice Instrument Technician?

Essential skills include basic electrical knowledge, troubleshooting abilities, proficiency in instrument control software, knowledge of instrument calibration and maintenance techniques, and familiarity with PLC and DCS systems configuration.

What is the role of an Apprentice Instrument Technician?

Apprentice Instrument Technicians assist in the installation, calibration, maintenance, and repair of instrumentation and control systems used in industrial settings, ensuring the efficient and safe operation of plant processes.

What are the career advancement opportunities for Apprentice Instrument Technicians?

With experience and further education, Apprentice Instrument Technicians can advance to roles such as Instrument Technician, Instrumentation Engineer, or Control Systems Engineer.

What is the typical work environment for an Apprentice Instrument Technician?

Apprentice Instrument Technicians typically work in industrial settings, such as petrochemical plants, power plants, or manufacturing facilities. They may work indoors or outdoors, in various weather conditions.

What are the safety considerations for Apprentice Instrument Technicians?

Apprentice Instrument Technicians must adhere to strict safety protocols and industry standards when working with electrical systems and potentially hazardous equipment. They must wear appropriate protective gear and follow established procedures to minimize risks.

What is the job outlook for Apprentice Instrument Technicians?

The job outlook for Apprentice Instrument Technicians is expected to be favorable due to the increasing demand for skilled technicians in the automation and instrumentation industry.

What are the educational requirements for an Apprentice Instrument Technician?

Apprentice Instrument Technicians typically have an associate’s degree in instrumentation technology or a related field. Some employers may also offer apprenticeship programs that combine on-the-job training with classroom instruction.

What are the salary expectations for Apprentice Instrument Technicians?

Salary expectations for Apprentice Instrument Technicians vary depending on experience, location, and industry. According to Indeed, the average salary for an Apprentice Instrument Technician in the United States is around $25,000 per year.