Are you a seasoned Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) seeking a new career path? Discover our professionally built Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

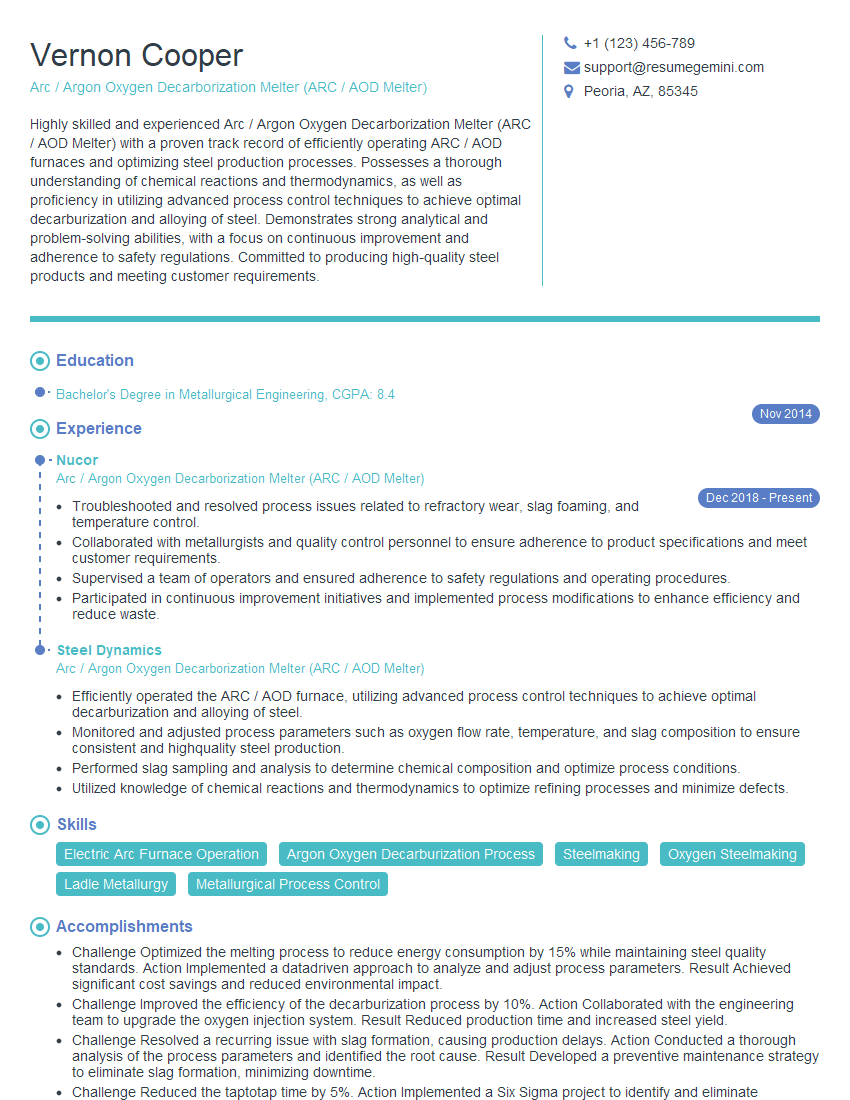

Vernon Cooper

Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)

Summary

Highly skilled and experienced Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) with a proven track record of efficiently operating ARC / AOD furnaces and optimizing steel production processes. Possesses a thorough understanding of chemical reactions and thermodynamics, as well as proficiency in utilizing advanced process control techniques to achieve optimal decarburization and alloying of steel. Demonstrates strong analytical and problem-solving abilities, with a focus on continuous improvement and adherence to safety regulations. Committed to producing high-quality steel products and meeting customer requirements.

Education

Bachelor’s Degree in Metallurgical Engineering

November 2014

Skills

- Electric Arc Furnace Operation

- Argon Oxygen Decarburization Process

- Steelmaking

- Oxygen Steelmaking

- Ladle Metallurgy

- Metallurgical Process Control

Work Experience

Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)

- Troubleshooted and resolved process issues related to refractory wear, slag foaming, and temperature control.

- Collaborated with metallurgists and quality control personnel to ensure adherence to product specifications and meet customer requirements.

- Supervised a team of operators and ensured adherence to safety regulations and operating procedures.

- Participated in continuous improvement initiatives and implemented process modifications to enhance efficiency and reduce waste.

Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)

- Efficiently operated the ARC / AOD furnace, utilizing advanced process control techniques to achieve optimal decarburization and alloying of steel.

- Monitored and adjusted process parameters such as oxygen flow rate, temperature, and slag composition to ensure consistent and highquality steel production.

- Performed slag sampling and analysis to determine chemical composition and optimize process conditions.

- Utilized knowledge of chemical reactions and thermodynamics to optimize refining processes and minimize defects.

Accomplishments

- Challenge Optimized the melting process to reduce energy consumption by 15% while maintaining steel quality standards. Action Implemented a datadriven approach to analyze and adjust process parameters. Result Achieved significant cost savings and reduced environmental impact.

- Challenge Improved the efficiency of the decarburization process by 10%. Action Collaborated with the engineering team to upgrade the oxygen injection system. Result Reduced production time and increased steel yield.

- Challenge Resolved a recurring issue with slag formation, causing production delays. Action Conducted a thorough analysis of the process parameters and identified the root cause. Result Developed a preventive maintenance strategy to eliminate slag formation, minimizing downtime.

- Challenge Reduced the taptotap time by 5%. Action Implemented a Six Sigma project to identify and eliminate bottlenecks in the process. Result Enhanced overall productivity and increased production capacity.

- Challenge Ensured the production of highquality steel by maintaining strict adherence to process specifications. Action Developed a comprehensive quality control program to monitor and adjust process parameters. Result Consistently met customer requirements and maintained a reputation for excellence.

Awards

- Received the Annual Production Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Recognized as the Safety Champion for implementing innovative safety protocols that significantly reduced accident rates.

- Awarded the Innovation Award for developing a costeffective method to enhance decarburization efficiency.

Certificates

- Certified ARC / AOD Melter

- American Welding Society Certified Welder

- National Institute for Certification in Engineering Technologies (NICET) Certification

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)

- Highlight your expertise in electric arc furnace operation and argon oxygen decarburization processes.

- Quantify your accomplishments and provide specific examples of how you have optimized steel production and reduced waste.

- Emphasize your ability to troubleshoot and resolve process issues effectively.

- Showcase your knowledge of chemical reactions and thermodynamics, and how you have applied this knowledge to improve refining processes.

- Demonstrate your commitment to safety and adherence to regulations.

Essential Experience Highlights for a Strong Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) Resume

- Efficiently operate and control the ARC / AOD furnace, utilizing advanced process control techniques to achieve optimal decarburization and alloying of steel.

- Monitor and adjust process parameters such as oxygen flow rate, temperature, and slag composition to ensure consistent and high-quality steel production.

- Analyze slag samples to determine chemical composition and optimize process conditions.

- Utilize knowledge of chemical reactions and thermodynamics to optimize refining processes and minimize defects.

- Troubleshoot and resolve process issues related to refractory wear, slag foaming, and temperature control.

- Collaborate with metallurgists and quality control personnel to ensure adherence to product specifications and meet customer requirements.

- Supervise a team of operators and ensure adherence to safety regulations and operating procedures.

Frequently Asked Questions (FAQ’s) For Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)

What are the primary responsibilities of an Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)?

The primary responsibilities include operating and controlling the ARC / AOD furnace, monitoring and adjusting process parameters, analyzing slag samples, troubleshooting process issues, and collaborating with metallurgists and quality control personnel to ensure adherence to product specifications.

What skills are required to be successful as an Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)?

Essential skills include proficiency in electric arc furnace operation, argon oxygen decarburization process, steelmaking, oxygen steelmaking, ladle metallurgy, and metallurgical process control.

What is the role of an Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) in the steel production process?

The ARC / AOD Melter plays a crucial role in refining molten steel, removing impurities, and achieving the desired steel composition through decarburization and alloying processes.

What are the safety considerations for Arc / Argon Oxygen Decarborization Melters (ARC / AOD Melters)?

Safety is paramount, and ARC / AOD Melters must adhere to strict safety regulations and operating procedures to minimize risks associated with high temperatures, molten metal, and hazardous materials.

What career advancement opportunities are available for Arc / Argon Oxygen Decarborization Melters (ARC / AOD Melters)?

With experience and expertise, ARC / AOD Melters can advance to positions such as Production Supervisor, Metallurgist, or Quality Control Manager.

What are the key challenges faced by Arc / Argon Oxygen Decarborization Melters (ARC / AOD Melters)?

Challenges include maintaining optimal furnace conditions, troubleshooting process issues efficiently, and ensuring consistent production of high-quality steel while adhering to safety regulations.