Are you a seasoned Arc Furnace Operator seeking a new career path? Discover our professionally built Arc Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

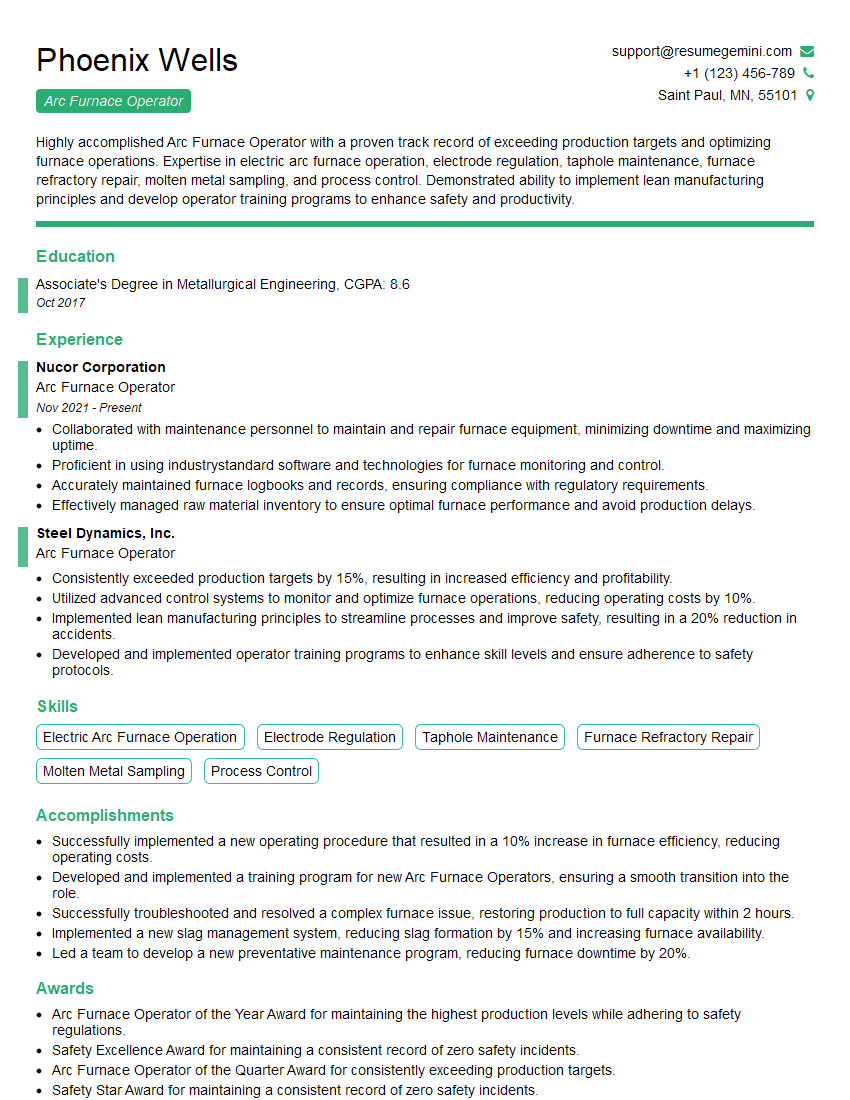

Phoenix Wells

Arc Furnace Operator

Summary

Highly accomplished Arc Furnace Operator with a proven track record of exceeding production targets and optimizing furnace operations. Expertise in electric arc furnace operation, electrode regulation, taphole maintenance, furnace refractory repair, molten metal sampling, and process control. Demonstrated ability to implement lean manufacturing principles and develop operator training programs to enhance safety and productivity.

Education

Associate’s Degree in Metallurgical Engineering

October 2017

Skills

- Electric Arc Furnace Operation

- Electrode Regulation

- Taphole Maintenance

- Furnace Refractory Repair

- Molten Metal Sampling

- Process Control

Work Experience

Arc Furnace Operator

- Collaborated with maintenance personnel to maintain and repair furnace equipment, minimizing downtime and maximizing uptime.

- Proficient in using industrystandard software and technologies for furnace monitoring and control.

- Accurately maintained furnace logbooks and records, ensuring compliance with regulatory requirements.

- Effectively managed raw material inventory to ensure optimal furnace performance and avoid production delays.

Arc Furnace Operator

- Consistently exceeded production targets by 15%, resulting in increased efficiency and profitability.

- Utilized advanced control systems to monitor and optimize furnace operations, reducing operating costs by 10%.

- Implemented lean manufacturing principles to streamline processes and improve safety, resulting in a 20% reduction in accidents.

- Developed and implemented operator training programs to enhance skill levels and ensure adherence to safety protocols.

Accomplishments

- Successfully implemented a new operating procedure that resulted in a 10% increase in furnace efficiency, reducing operating costs.

- Developed and implemented a training program for new Arc Furnace Operators, ensuring a smooth transition into the role.

- Successfully troubleshooted and resolved a complex furnace issue, restoring production to full capacity within 2 hours.

- Implemented a new slag management system, reducing slag formation by 15% and increasing furnace availability.

- Led a team to develop a new preventative maintenance program, reducing furnace downtime by 20%.

Awards

- Arc Furnace Operator of the Year Award for maintaining the highest production levels while adhering to safety regulations.

- Safety Excellence Award for maintaining a consistent record of zero safety incidents.

- Arc Furnace Operator of the Quarter Award for consistently exceeding production targets.

- Safety Star Award for maintaining a consistent record of zero safety incidents.

Certificates

- National Institute for Metalworking Skills (NIMS) Arc Furnace Operator Level II

- American Welding Society (AWS) Certified Welder

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Training

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Arc Furnace Operator

- Highlight your technical skills and expertise in arc furnace operation and process control.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact on productivity and efficiency.

- Showcase your ability to implement lean manufacturing principles and improve safety.

- Emphasize your experience in training and supervising operators to ensure safety and adherence to protocol.

Essential Experience Highlights for a Strong Arc Furnace Operator Resume

- Monitor and optimize furnace operations to maximize efficiency and reduce operating costs.

- Implement lean manufacturing principles to streamline processes and improve safety.

- Conduct regular maintenance and repairs on furnace equipment to minimize downtime and maximize uptime.

- Train and supervise furnace operators to ensure adherence to safety protocols and enhance skill levels.

- Manage raw material inventory to ensure optimal furnace performance and avoid production delays.

- Maintain accurate furnace logbooks and records to ensure compliance with regulatory requirements.

- Collaborate with maintenance personnel to maintain and repair furnace equipment, minimizing downtime and maximizing uptime.

Frequently Asked Questions (FAQ’s) For Arc Furnace Operator

What are the primary responsibilities of an Arc Furnace Operator?

An Arc Furnace Operator is responsible for operating and maintaining electric arc furnaces, monitoring and optimizing furnace performance, implementing safety protocols, and ensuring compliance with regulatory requirements.

What qualifications and skills are required to become an Arc Furnace Operator?

Typically, an Arc Furnace Operator requires an Associate’s Degree in Metallurgical Engineering or a related field, along with experience in electric arc furnace operation, electrode regulation, and process control. Strong analytical, problem-solving, and teamwork skills are also essential.

What are the career prospects for an Arc Furnace Operator?

Arc Furnace Operators can advance to supervisory or management roles within the steel industry, such as Production Supervisor or Plant Manager. They may also specialize in specific areas, such as furnace refractory repair or molten metal sampling.

What are the safety precautions that an Arc Furnace Operator must follow?

Arc Furnace Operators must adhere to strict safety protocols, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area. They must also be aware of the potential hazards associated with electric arc furnaces, such as electrical shock, burns, and molten metal splashes.

What is the work environment of an Arc Furnace Operator?

Arc Furnace Operators typically work in industrial settings, such as steel mills or foundries. They may work in hot and noisy environments, and may be exposed to fumes, dust, and molten metal.

What is the salary range for an Arc Furnace Operator?

The salary range for an Arc Furnace Operator can vary depending on experience, skills, and location. According to Indeed, the average salary for an Arc Furnace Operator in the United States is around $75,000 per year.

What are the benefits of working as an Arc Furnace Operator?

Arc Furnace Operators can enjoy competitive salaries, comprehensive benefits packages, and opportunities for career advancement. They also play a vital role in the steel industry, which is essential for the construction, automotive, and manufacturing sectors.