Are you a seasoned Assembly Department Supervisor seeking a new career path? Discover our professionally built Assembly Department Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

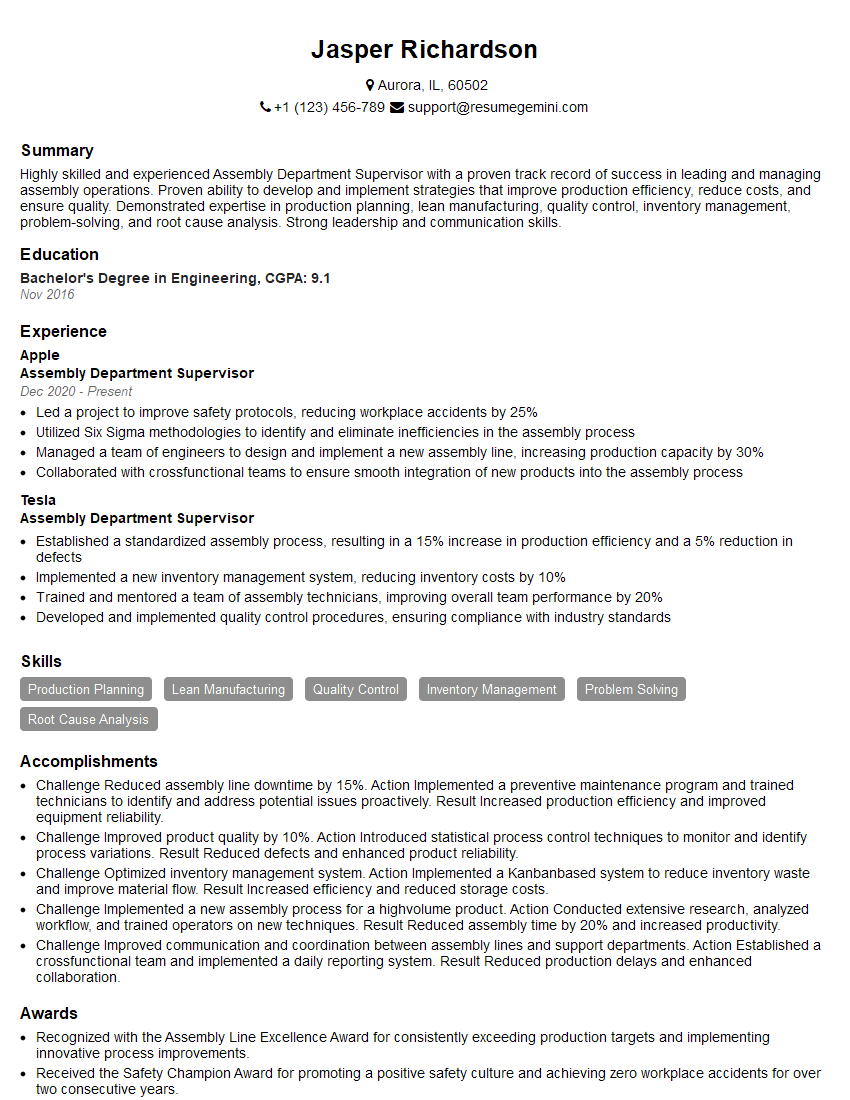

Jasper Richardson

Assembly Department Supervisor

Summary

Highly skilled and experienced Assembly Department Supervisor with a proven track record of success in leading and managing assembly operations. Proven ability to develop and implement strategies that improve production efficiency, reduce costs, and ensure quality. Demonstrated expertise in production planning, lean manufacturing, quality control, inventory management, problem-solving, and root cause analysis. Strong leadership and communication skills.

Education

Bachelor’s Degree in Engineering

November 2016

Skills

- Production Planning

- Lean Manufacturing

- Quality Control

- Inventory Management

- Problem Solving

- Root Cause Analysis

Work Experience

Assembly Department Supervisor

- Led a project to improve safety protocols, reducing workplace accidents by 25%

- Utilized Six Sigma methodologies to identify and eliminate inefficiencies in the assembly process

- Managed a team of engineers to design and implement a new assembly line, increasing production capacity by 30%

- Collaborated with crossfunctional teams to ensure smooth integration of new products into the assembly process

Assembly Department Supervisor

- Established a standardized assembly process, resulting in a 15% increase in production efficiency and a 5% reduction in defects

- Implemented a new inventory management system, reducing inventory costs by 10%

- Trained and mentored a team of assembly technicians, improving overall team performance by 20%

- Developed and implemented quality control procedures, ensuring compliance with industry standards

Accomplishments

- Challenge Reduced assembly line downtime by 15%. Action Implemented a preventive maintenance program and trained technicians to identify and address potential issues proactively. Result Increased production efficiency and improved equipment reliability.

- Challenge Improved product quality by 10%. Action Introduced statistical process control techniques to monitor and identify process variations. Result Reduced defects and enhanced product reliability.

- Challenge Optimized inventory management system. Action Implemented a Kanbanbased system to reduce inventory waste and improve material flow. Result Increased efficiency and reduced storage costs.

- Challenge Implemented a new assembly process for a highvolume product. Action Conducted extensive research, analyzed workflow, and trained operators on new techniques. Result Reduced assembly time by 20% and increased productivity.

- Challenge Improved communication and coordination between assembly lines and support departments. Action Established a crossfunctional team and implemented a daily reporting system. Result Reduced production delays and enhanced collaboration.

Awards

- Recognized with the Assembly Line Excellence Award for consistently exceeding production targets and implementing innovative process improvements.

- Received the Safety Champion Award for promoting a positive safety culture and achieving zero workplace accidents for over two consecutive years.

- Recognized with the Employee of the Month award for consistently exceeding performance expectations and demonstrating exceptional leadership skills.

- Received the Team Leader of the Year award for successfully managing a team of 20+ assembly line operators and consistently achieving production targets.

Certificates

- Certified Assembly Technician (CAT)

- Certified Lean Manufacturing Professional (CLMP)

- Certified Manager of Quality/Operational Excellence (CMQ/OE)

- Certified Production and Inventory Manager (CPIM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Assembly Department Supervisor

- Quantify your accomplishments with specific metrics whenever possible.

- Use action verbs to highlight your skills and responsibilities.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant.

- Proofread your resume carefully before submitting it.

- Get feedback on your resume from a career counselor or other professionals.

Essential Experience Highlights for a Strong Assembly Department Supervisor Resume

- Plan and schedule production activities to meet customer demand and production targets.

- Establish and implement quality control procedures to ensure compliance with industry standards.

- Train and mentor assembly technicians to improve team performance and skill development.

- Supervise and manage a team of assembly technicians to ensure efficient and effective operations.

- Identify and resolve production issues promptly to minimize downtime and maintain production schedules.

- Collaborate with cross-functional teams to ensure smooth integration of new products and processes.

- Utilize Six Sigma methodologies to improve processes and reduce waste.

Frequently Asked Questions (FAQ’s) For Assembly Department Supervisor

What are the key skills and qualifications for an Assembly Department Supervisor?

Key skills and qualifications for an Assembly Department Supervisor include production planning, lean manufacturing, quality control, inventory management, problem-solving, root cause analysis, and leadership.

What are the primary responsibilities of an Assembly Department Supervisor?

The primary responsibilities of an Assembly Department Supervisor include planning and scheduling production activities, establishing and implementing quality control procedures, training and mentoring assembly technicians, supervising and managing a team of assembly technicians, and collaborating with cross-functional teams.

What are the career advancement opportunities for an Assembly Department Supervisor?

Career advancement opportunities for an Assembly Department Supervisor include Production Manager, Operations Manager, and Plant Manager.

What is the average salary for an Assembly Department Supervisor?

The average salary for an Assembly Department Supervisor in the United States is around $75,000 per year.

What are the challenges faced by Assembly Department Supervisors?

Challenges faced by Assembly Department Supervisors include meeting production targets, maintaining quality standards, managing a team of employees, and dealing with production issues.

What are the key trends in the Assembly Department Supervisor industry?

Key trends in the Assembly Department Supervisor industry include the adoption of lean manufacturing principles, the use of automation and robotics, and the increasing focus on quality and customer satisfaction.