Are you a seasoned Assembly Inspector seeking a new career path? Discover our professionally built Assembly Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

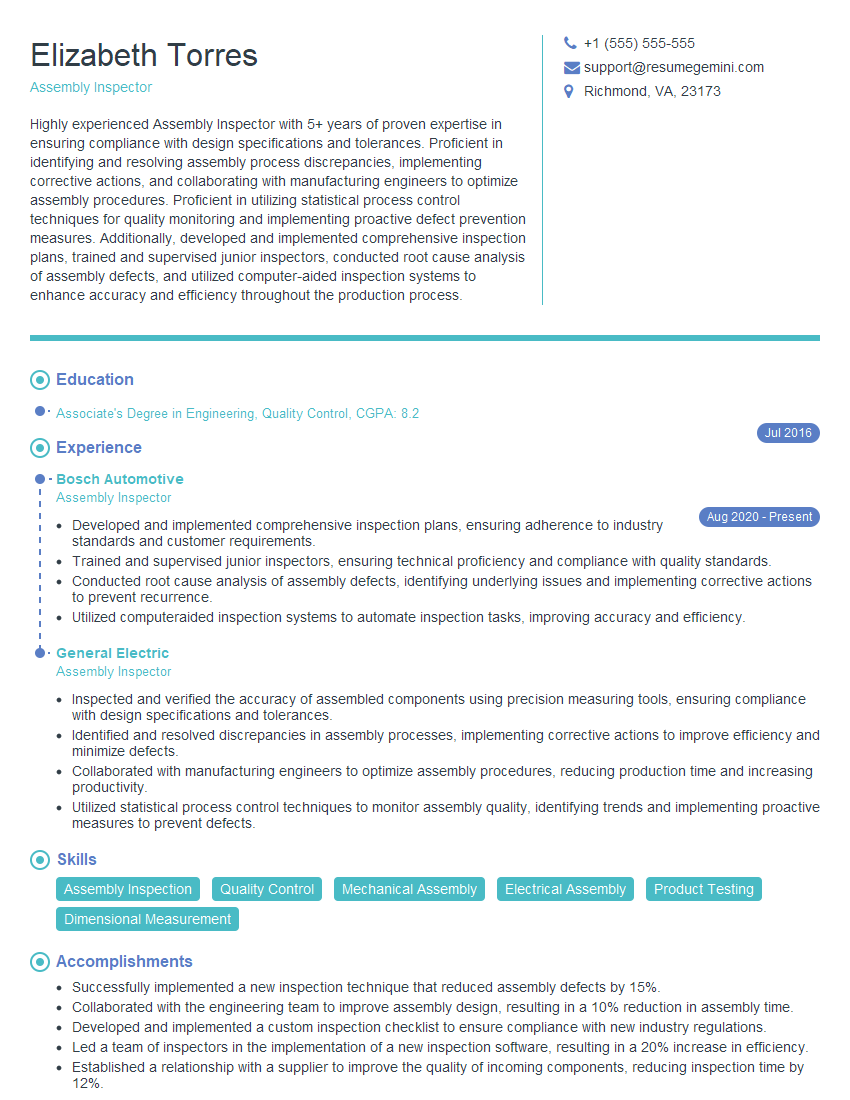

Elizabeth Torres

Assembly Inspector

Summary

Highly experienced Assembly Inspector with 5+ years of proven expertise in ensuring compliance with design specifications and tolerances. Proficient in identifying and resolving assembly process discrepancies, implementing corrective actions, and collaborating with manufacturing engineers to optimize assembly procedures. Proficient in utilizing statistical process control techniques for quality monitoring and implementing proactive defect prevention measures. Additionally, developed and implemented comprehensive inspection plans, trained and supervised junior inspectors, conducted root cause analysis of assembly defects, and utilized computer-aided inspection systems to enhance accuracy and efficiency throughout the production process.

Education

Associate’s Degree in Engineering, Quality Control

July 2016

Skills

- Assembly Inspection

- Quality Control

- Mechanical Assembly

- Electrical Assembly

- Product Testing

- Dimensional Measurement

Work Experience

Assembly Inspector

- Developed and implemented comprehensive inspection plans, ensuring adherence to industry standards and customer requirements.

- Trained and supervised junior inspectors, ensuring technical proficiency and compliance with quality standards.

- Conducted root cause analysis of assembly defects, identifying underlying issues and implementing corrective actions to prevent recurrence.

- Utilized computeraided inspection systems to automate inspection tasks, improving accuracy and efficiency.

Assembly Inspector

- Inspected and verified the accuracy of assembled components using precision measuring tools, ensuring compliance with design specifications and tolerances.

- Identified and resolved discrepancies in assembly processes, implementing corrective actions to improve efficiency and minimize defects.

- Collaborated with manufacturing engineers to optimize assembly procedures, reducing production time and increasing productivity.

- Utilized statistical process control techniques to monitor assembly quality, identifying trends and implementing proactive measures to prevent defects.

Accomplishments

- Successfully implemented a new inspection technique that reduced assembly defects by 15%.

- Collaborated with the engineering team to improve assembly design, resulting in a 10% reduction in assembly time.

- Developed and implemented a custom inspection checklist to ensure compliance with new industry regulations.

- Led a team of inspectors in the implementation of a new inspection software, resulting in a 20% increase in efficiency.

- Established a relationship with a supplier to improve the quality of incoming components, reducing inspection time by 12%.

Awards

- Received Inspector of the Quarter award for maintaining a 99.9% accuracy rate in assembly inspections.

- Honored with the Excellence in Quality Control award for consistently exceeding assembly inspection standards.

- Recognized for exceptional problemsolving skills during a critical assembly process issue.

- Awarded the Exceptional Performance honor for consistently exceeding inspection quotas while maintaining accuracy.

Certificates

- Certified Assembly Inspector (CAI) – International Association for Six Sigma Certification (IASSC)

- Certified Quality Inspector (CQI) – American Society for Quality (ASQ)

- Certified Product Inspector (CPI) – American Welding Society (AWS)

- ISO 9001:2015 Internal Auditor Certification – Exemplar Global

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Assembly Inspector

- When writing your resume, be sure to highlight your skills and experience in assembly inspection.

- Quantify your achievements whenever possible to demonstrate the impact of your work.

- Showcase your knowledge of quality control standards and procedures.

- Highlight your ability to troubleshoot and resolve assembly issues.

- Be sure to tailor your resume to the specific job you are applying for.

Essential Experience Highlights for a Strong Assembly Inspector Resume

- Inspected and verified the accuracy of assembled components using precision measuring tools.

- Identified and resolved discrepancies in assembly processes, implementing corrective actions to improve efficiency and minimize defects.

- Collaborated with manufacturing engineers to optimize assembly procedures, reducing production time and increasing productivity.

- Utilized statistical process control techniques to monitor assembly quality, identifying trends and implementing proactive measures to prevent defects.

- Developed and implemented comprehensive inspection plans, ensuring adherence to industry standards and customer requirements.

- Trained and supervised junior inspectors, ensuring technical proficiency and compliance with quality standards.

- Conducted root cause analysis of assembly defects, identifying underlying issues and implementing corrective actions to prevent recurrence.

- Utilized computer-aided inspection systems to automate inspection tasks, improving accuracy and efficiency.

Frequently Asked Questions (FAQ’s) For Assembly Inspector

What is the role of an Assembly Inspector?

Assembly Inspectors are responsible for ensuring that assembled components meet design specifications and tolerances. They inspect and verify the accuracy of assembled components using precision measuring tools, identify and resolve discrepancies in assembly processes, and collaborate with manufacturing engineers to optimize assembly procedures.

What are the key skills required for an Assembly Inspector?

Key skills for an Assembly Inspector include the ability to inspect and verify the accuracy of assembled components using precision measuring tools, identify and resolve discrepancies in assembly processes, collaborate with manufacturing engineers to optimize assembly procedures, and utilize statistical process control techniques to monitor assembly quality.

What are the career prospects for an Assembly Inspector?

Assembly Inspectors can advance their careers by becoming Quality Control Inspectors, Manufacturing Engineers, or Production Supervisors. With additional education and experience, they can also move into management positions.

What is the average salary for an Assembly Inspector?

The average salary for an Assembly Inspector in the United States is $40,000 per year.

What are the benefits of working as an Assembly Inspector?

Benefits of working as an Assembly Inspector include job security, the opportunity to work with a variety of products, and the chance to make a difference in the quality of manufactured goods.

What are the challenges of working as an Assembly Inspector?

Challenges of working as an Assembly Inspector include the need to work in a fast-paced environment, the potential for repetitive tasks, and the need to work with precision measuring tools.

What is the work environment of an Assembly Inspector like?

Assembly Inspectors typically work in a manufacturing environment. They may work in a variety of settings, including factories, warehouses, and laboratories.

What are the hours of work for an Assembly Inspector?

Assembly Inspectors typically work full-time hours. They may work overtime to meet production deadlines.