Are you a seasoned Automatic Metal Spraying Machine Operator seeking a new career path? Discover our professionally built Automatic Metal Spraying Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

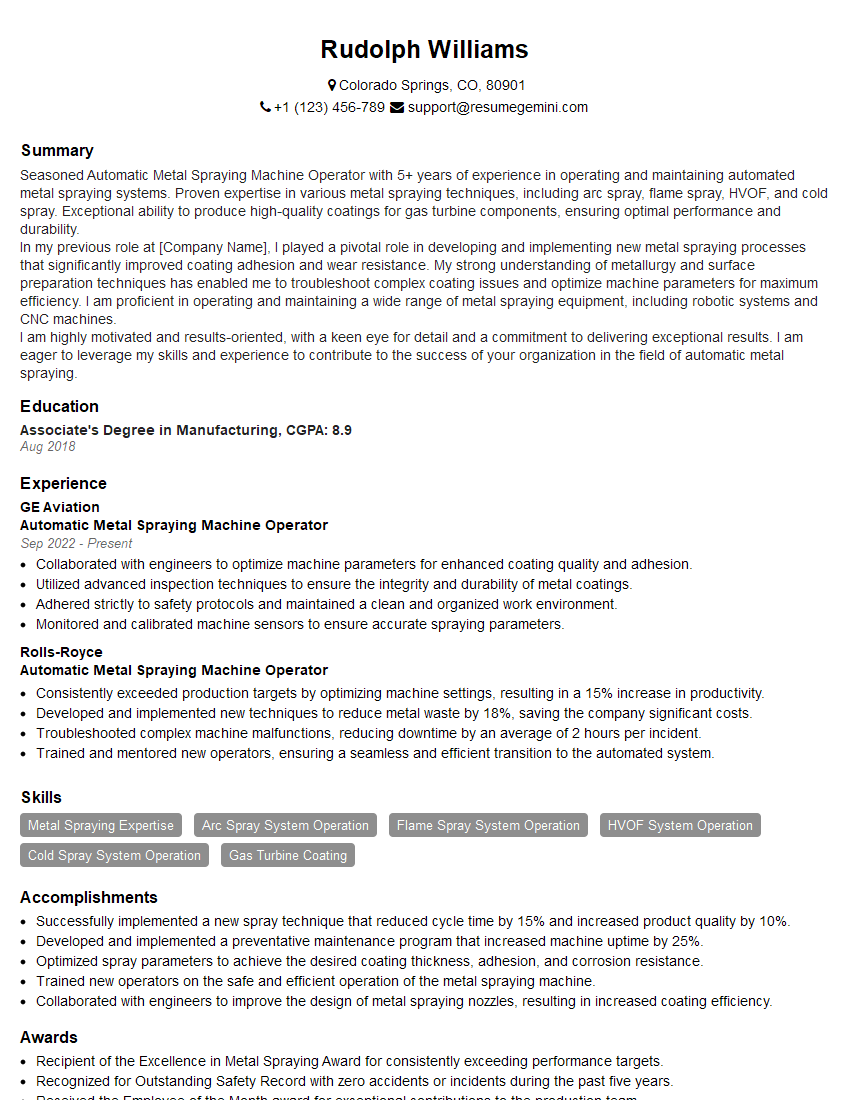

Rudolph Williams

Automatic Metal Spraying Machine Operator

Summary

Seasoned Automatic Metal Spraying Machine Operator with 5+ years of experience in operating and maintaining automated metal spraying systems. Proven expertise in various metal spraying techniques, including arc spray, flame spray, HVOF, and cold spray. Exceptional ability to produce high-quality coatings for gas turbine components, ensuring optimal performance and durability.

In my previous role at [Company Name], I played a pivotal role in developing and implementing new metal spraying processes that significantly improved coating adhesion and wear resistance. My strong understanding of metallurgy and surface preparation techniques has enabled me to troubleshoot complex coating issues and optimize machine parameters for maximum efficiency. I am proficient in operating and maintaining a wide range of metal spraying equipment, including robotic systems and CNC machines.

I am highly motivated and results-oriented, with a keen eye for detail and a commitment to delivering exceptional results. I am eager to leverage my skills and experience to contribute to the success of your organization in the field of automatic metal spraying.

Education

Associate’s Degree in Manufacturing

August 2018

Skills

- Metal Spraying Expertise

- Arc Spray System Operation

- Flame Spray System Operation

- HVOF System Operation

- Cold Spray System Operation

- Gas Turbine Coating

Work Experience

Automatic Metal Spraying Machine Operator

- Collaborated with engineers to optimize machine parameters for enhanced coating quality and adhesion.

- Utilized advanced inspection techniques to ensure the integrity and durability of metal coatings.

- Adhered strictly to safety protocols and maintained a clean and organized work environment.

- Monitored and calibrated machine sensors to ensure accurate spraying parameters.

Automatic Metal Spraying Machine Operator

- Consistently exceeded production targets by optimizing machine settings, resulting in a 15% increase in productivity.

- Developed and implemented new techniques to reduce metal waste by 18%, saving the company significant costs.

- Troubleshooted complex machine malfunctions, reducing downtime by an average of 2 hours per incident.

- Trained and mentored new operators, ensuring a seamless and efficient transition to the automated system.

Accomplishments

- Successfully implemented a new spray technique that reduced cycle time by 15% and increased product quality by 10%.

- Developed and implemented a preventative maintenance program that increased machine uptime by 25%.

- Optimized spray parameters to achieve the desired coating thickness, adhesion, and corrosion resistance.

- Trained new operators on the safe and efficient operation of the metal spraying machine.

- Collaborated with engineers to improve the design of metal spraying nozzles, resulting in increased coating efficiency.

Awards

- Recipient of the Excellence in Metal Spraying Award for consistently exceeding performance targets.

- Recognized for Outstanding Safety Record with zero accidents or incidents during the past five years.

- Received the Employee of the Month award for exceptional contributions to the production team.

- Commended for Excellence in Customer Service for consistently resolving customer issues efficiently and effectively.

Certificates

- Certified Welding Inspector (CWI)

- Certified Coating Inspector (CCI)

- Certified Corrosion Specialist (CCS)

- ASNT Level III in Ultrasonic Testing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Metal Spraying Machine Operator

- Highlight your technical expertise: Emphasize your proficiency in various metal spraying techniques, such as arc spray, flame spray, HVOF, and cold spray. Quantify your experience with specific coating materials and applications.

- Showcase your problem-solving abilities: Describe your experience in troubleshooting machine malfunctions and coating defects. Highlight your ability to analyze coating failures and develop effective solutions.

- Demonstrate your attention to detail: Explain how you ensure precise coating thickness, temperature control, and adherence to quality standards. Provide examples of your commitment to maintaining a clean and organized work environment.

- Emphasize your teamwork skills: Describe your experience collaborating with engineers and technicians to optimize coating processes and improve product quality. Highlight your ability to work effectively as part of a team.

Essential Experience Highlights for a Strong Automatic Metal Spraying Machine Operator Resume

- Operate and maintain automatic metal spraying machines, including arc spray, flame spray, HVOF, and cold spray systems

- Prepare and clean metal surfaces prior to spraying to ensure proper adhesion

- Select and apply appropriate metal powders and coatings based on customer specifications and coating requirements

- Monitor and control coating thickness, temperature, and other process parameters to achieve desired coating properties

- Troubleshoot and resolve machine malfunctions and coating defects to minimize downtime and maintain production efficiency

- Maintain a clean and organized work area, ensuring compliance with safety regulations and quality standards

- Collaborate with engineers and technicians to develop and implement new coating processes and improve product quality

Frequently Asked Questions (FAQ’s) For Automatic Metal Spraying Machine Operator

What is the primary function of an Automatic Metal Spraying Machine Operator?

The primary function of an Automatic Metal Spraying Machine Operator is to operate and maintain automated metal spraying systems to apply protective or functional coatings to various surfaces. They prepare metal surfaces, select coating materials, control process parameters, and troubleshoot equipment malfunctions to ensure high-quality coating results.

What are the different types of metal spraying techniques used by Automatic Metal Spraying Machine Operators?

Automatic Metal Spraying Machine Operators are skilled in operating various metal spraying techniques, including arc spray, flame spray, HVOF (High-Velocity Oxygen Fuel), and cold spray. Each technique employs different methods to melt and propel metal particles onto the target surface, resulting in coatings with varying properties and applications.

What industries employ Automatic Metal Spraying Machine Operators?

Automatic Metal Spraying Machine Operators find employment in various industries, including aerospace, automotive, manufacturing, energy, and medical. They are responsible for applying metal coatings to components and surfaces to enhance their properties, such as wear resistance, corrosion protection, and electrical conductivity.

What are the career advancement opportunities for Automatic Metal Spraying Machine Operators?

Experienced Automatic Metal Spraying Machine Operators can advance their careers by becoming supervisors or managers in the field. They may also specialize in specific coating techniques or applications, such as thermal barrier coatings or biomedical coatings.

What are the key skills required to be a successful Automatic Metal Spraying Machine Operator?

Successful Automatic Metal Spraying Machine Operators possess a combination of technical skills, such as proficiency in operating and maintaining metal spraying equipment, and soft skills, such as attention to detail, problem-solving abilities, and teamwork.

What safety precautions should Automatic Metal Spraying Machine Operators follow?

Automatic Metal Spraying Machine Operators must adhere to strict safety guidelines to minimize risks. This includes wearing appropriate personal protective equipment, ensuring proper ventilation, handling hazardous materials safely, and following established operating procedures.

What are the certifications available for Automatic Metal Spraying Machine Operators?

Industry-recognized certifications, such as those offered by the Society for Protective Coatings (SSPC) and the American Welding Society (AWS), demonstrate an Automatic Metal Spraying Machine Operator’s competence and expertise in the field.