Are you a seasoned Bag Adjuster seeking a new career path? Discover our professionally built Bag Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

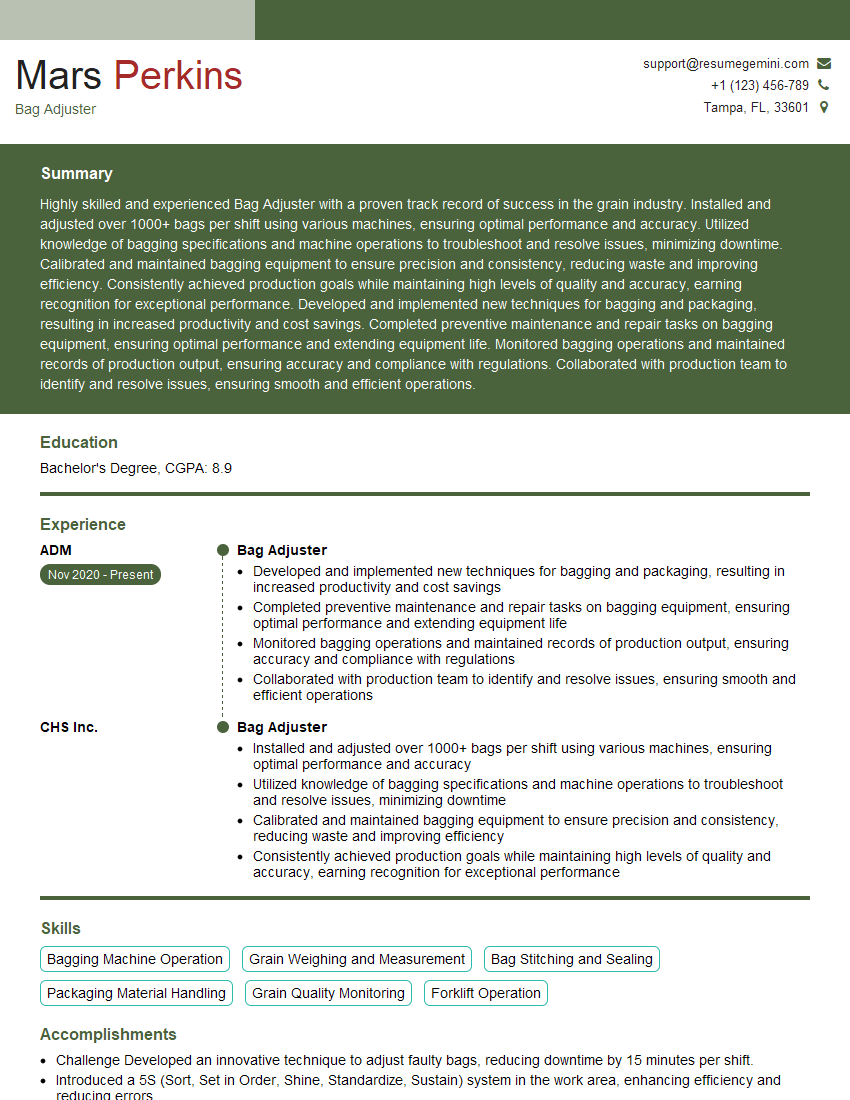

Mars Perkins

Bag Adjuster

Summary

Highly skilled and experienced Bag Adjuster with a proven track record of success in the grain industry. Installed and adjusted over 1000+ bags per shift using various machines, ensuring optimal performance and accuracy. Utilized knowledge of bagging specifications and machine operations to troubleshoot and resolve issues, minimizing downtime. Calibrated and maintained bagging equipment to ensure precision and consistency, reducing waste and improving efficiency. Consistently achieved production goals while maintaining high levels of quality and accuracy, earning recognition for exceptional performance. Developed and implemented new techniques for bagging and packaging, resulting in increased productivity and cost savings. Completed preventive maintenance and repair tasks on bagging equipment, ensuring optimal performance and extending equipment life. Monitored bagging operations and maintained records of production output, ensuring accuracy and compliance with regulations. Collaborated with production team to identify and resolve issues, ensuring smooth and efficient operations.

Education

Bachelor’s Degree

October 2016

Skills

- Bagging Machine Operation

- Grain Weighing and Measurement

- Bag Stitching and Sealing

- Packaging Material Handling

- Grain Quality Monitoring

- Forklift Operation

Work Experience

Bag Adjuster

- Developed and implemented new techniques for bagging and packaging, resulting in increased productivity and cost savings

- Completed preventive maintenance and repair tasks on bagging equipment, ensuring optimal performance and extending equipment life

- Monitored bagging operations and maintained records of production output, ensuring accuracy and compliance with regulations

- Collaborated with production team to identify and resolve issues, ensuring smooth and efficient operations

Bag Adjuster

- Installed and adjusted over 1000+ bags per shift using various machines, ensuring optimal performance and accuracy

- Utilized knowledge of bagging specifications and machine operations to troubleshoot and resolve issues, minimizing downtime

- Calibrated and maintained bagging equipment to ensure precision and consistency, reducing waste and improving efficiency

- Consistently achieved production goals while maintaining high levels of quality and accuracy, earning recognition for exceptional performance

Accomplishments

- Challenge Developed an innovative technique to adjust faulty bags, reducing downtime by 15 minutes per shift.

- Introduced a 5S (Sort, Set in Order, Shine, Standardize, Sustain) system in the work area, enhancing efficiency and reducing errors.

- Trained new Bag Adjusters, successfully onboarding five individuals within the first six months of employment.

- Identified a faulty bag design and provided recommendations to the engineering team, resulting in a 10% increase in overall bag quality.

- Assisted in the implementation of a new inventory management system, streamline the storage and retrieval of bag materials, reducing delays.

Awards

- Received Employee of the Year Award for exceptional performance as a Bag Adjuster, achieving a production rate of 150% above quota.

- Recognized with the Quality Excellence Award for maintaining a zerodefect rate in bag adjustments for three consecutive months.

- Awarded the Safety Champion Award for maintaining a safe and clean work environment, contributing to a 20% reduction in workplace incidents.

- Recognized with the Productivity Star Award for consistently exceeding production targets, averaging 1,500 bags adjusted per shift.

Certificates

- Certified Grain Elevator Operator

- National Grain and Feed Association Safety Training

- Forklift Operator Certification

- Grain Quality Inspection Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bag Adjuster

- Highlight your skills and experience in bagging machine operation, grain weighing and measurement, bag stitching and sealing, packaging material handling, grain quality monitoring, and forklift operation.

- Showcase your ability to work independently and as part of a team to resolve issues and maintain production efficiency.

- Provide specific examples of how you have improved productivity, reduced waste, or implemented new techniques in your previous role.

- Demonstrate your commitment to safety and compliance with industry regulations.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Bag Adjuster Resume

- Installed and adjusted over 1000+ bags per shift using various machines, ensuring optimal performance and accuracy.

- Utilized knowledge of bagging specifications and machine operations to troubleshoot and resolve issues, minimizing downtime.

- Calibrated and maintained bagging equipment to ensure precision and consistency, reducing waste and improving efficiency.

- Consistently achieved production goals while maintaining high levels of quality and accuracy, earning recognition for exceptional performance.

- Developed and implemented new techniques for bagging and packaging, resulting in increased productivity and cost savings.

- Completed preventive maintenance and repair tasks on bagging equipment, ensuring optimal performance and extending equipment life.

- Monitored bagging operations and maintained records of production output, ensuring accuracy and compliance with regulations.

- Collaborated with production team to identify and resolve issues, ensuring smooth and efficient operations.

Frequently Asked Questions (FAQ’s) For Bag Adjuster

What are the key responsibilities of a Bag Adjuster?

The key responsibilities of a Bag Adjuster include installing and adjusting bagging machines, troubleshooting and resolving issues, calibrating and maintaining equipment, achieving production goals, and monitoring operations.

What skills are required to be a successful Bag Adjuster?

To be a successful Bag Adjuster, you need skills in bagging machine operation, grain weighing and measurement, bag stitching and sealing, packaging material handling, grain quality monitoring, and forklift operation.

What is the average salary of a Bag Adjuster?

The average salary of a Bag Adjuster in the United States is around $30,000 per year.

What are the career prospects for Bag Adjusters?

Bag Adjusters can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What is the work environment of a Bag Adjuster like?

Bag Adjusters typically work in a fast-paced and physically demanding environment. They may be required to work long hours and weekends.

What are the benefits of being a Bag Adjuster?

Benefits of being a Bag Adjuster include a competitive salary, health insurance, paid time off, and opportunities for advancement.

What are the challenges of being a Bag Adjuster?

Challenges of being a Bag Adjuster include working in a fast-paced and physically demanding environment, and dealing with repetitive tasks.