Are you a seasoned Barrel Rib Matting Machine Operator seeking a new career path? Discover our professionally built Barrel Rib Matting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

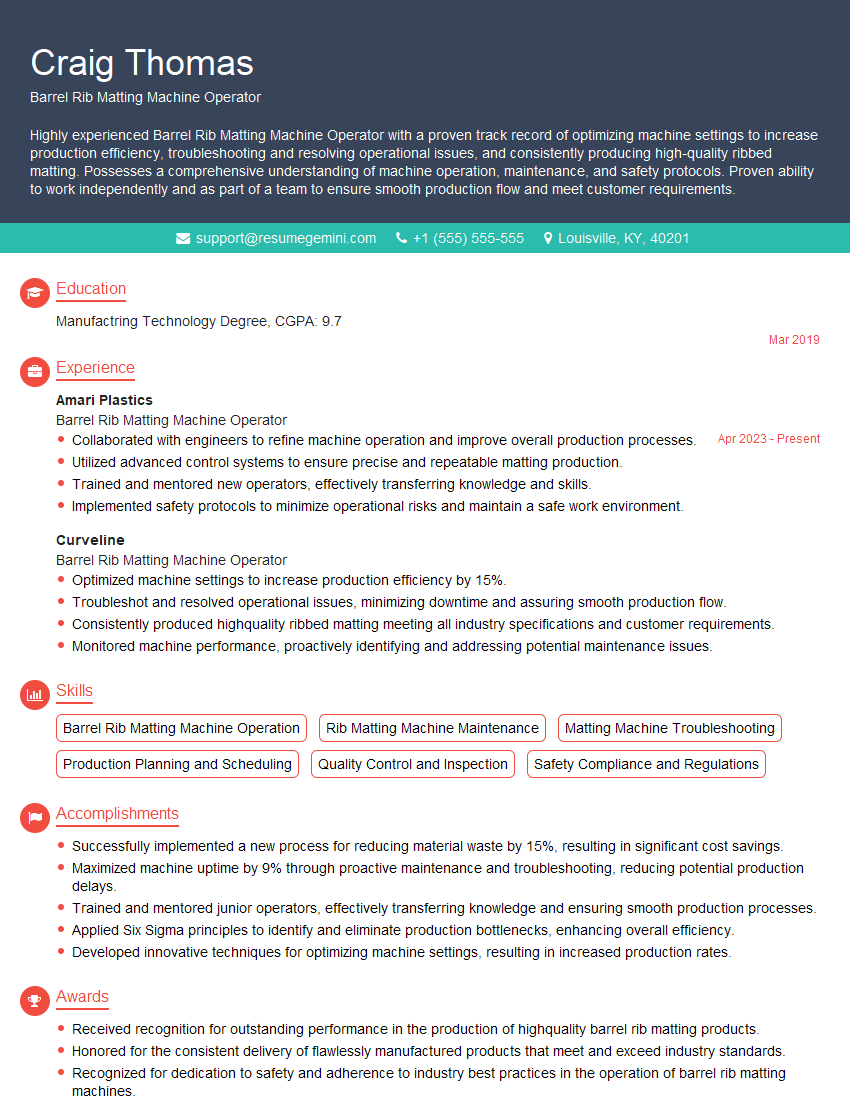

Craig Thomas

Barrel Rib Matting Machine Operator

Summary

Highly experienced Barrel Rib Matting Machine Operator with a proven track record of optimizing machine settings to increase production efficiency, troubleshooting and resolving operational issues, and consistently producing high-quality ribbed matting. Possesses a comprehensive understanding of machine operation, maintenance, and safety protocols. Proven ability to work independently and as part of a team to ensure smooth production flow and meet customer requirements.

Education

Manufactring Technology Degree

March 2019

Skills

- Barrel Rib Matting Machine Operation

- Rib Matting Machine Maintenance

- Matting Machine Troubleshooting

- Production Planning and Scheduling

- Quality Control and Inspection

- Safety Compliance and Regulations

Work Experience

Barrel Rib Matting Machine Operator

- Collaborated with engineers to refine machine operation and improve overall production processes.

- Utilized advanced control systems to ensure precise and repeatable matting production.

- Trained and mentored new operators, effectively transferring knowledge and skills.

- Implemented safety protocols to minimize operational risks and maintain a safe work environment.

Barrel Rib Matting Machine Operator

- Optimized machine settings to increase production efficiency by 15%.

- Troubleshot and resolved operational issues, minimizing downtime and assuring smooth production flow.

- Consistently produced highquality ribbed matting meeting all industry specifications and customer requirements.

- Monitored machine performance, proactively identifying and addressing potential maintenance issues.

Accomplishments

- Successfully implemented a new process for reducing material waste by 15%, resulting in significant cost savings.

- Maximized machine uptime by 9% through proactive maintenance and troubleshooting, reducing potential production delays.

- Trained and mentored junior operators, effectively transferring knowledge and ensuring smooth production processes.

- Applied Six Sigma principles to identify and eliminate production bottlenecks, enhancing overall efficiency.

- Developed innovative techniques for optimizing machine settings, resulting in increased production rates.

Awards

- Received recognition for outstanding performance in the production of highquality barrel rib matting products.

- Honored for the consistent delivery of flawlessly manufactured products that meet and exceed industry standards.

- Recognized for dedication to safety and adherence to industry best practices in the operation of barrel rib matting machines.

- Received acknowledgment for maintaining a spotless work area and adhering to stringent hygiene standards.

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certification

- National Institute for Certification in Engineering Technologies (NICET) Certification

- American Society for Nondestructive Testing (ASNT) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Barrel Rib Matting Machine Operator

- Highlight your experience in operating and maintaining barrel rib matting machines, quantifying your accomplishments whenever possible.

- Demonstrate your knowledge of production planning and scheduling, as well as quality control and inspection procedures.

- Emphasize your ability to work independently and as part of a team, troubleshooting and resolving issues to ensure smooth production flow.

- Showcase your commitment to safety by highlighting your understanding and implementation of safety protocols.

Essential Experience Highlights for a Strong Barrel Rib Matting Machine Operator Resume

- Optimized machine settings to increase production efficiency by 15%.

- Troubleshot and resolved operational issues, minimizing downtime and ensuring smooth production flow.

- Consistently produced high-quality ribbed matting meeting all industry specifications and customer requirements.

- Monitored machine performance, proactively identifying and addressing potential maintenance issues.

- Collaborated with engineers to refine machine operation and improve overall production processes.

- Utilized advanced control systems to ensure precise and repeatable matting production.

- Trained and mentored new operators, effectively transferring knowledge and skills.

Frequently Asked Questions (FAQ’s) For Barrel Rib Matting Machine Operator

What are the key skills required for a Barrel Rib Matting Machine Operator?

Key skills for a Barrel Rib Matting Machine Operator include barrel rib matting machine operation, rib matting machine maintenance, matting machine troubleshooting, production planning and scheduling, quality control and inspection, safety compliance, and regulations.

What are the typical responsibilities of a Barrel Rib Matting Machine Operator?

Typical responsibilities include operating and maintaining barrel rib matting machines, ensuring machine efficiency, troubleshooting and resolving operational issues, producing high-quality ribbed matting, monitoring machine performance, collaborating with engineers to improve production processes, and adhering to safety protocols.

What qualifications are required to become a Barrel Rib Matting Machine Operator?

Qualifications for a Barrel Rib Matting Machine Operator typically include a high school diploma or equivalent, with preferred experience in operating and maintaining industrial machinery. Some employers may require a Manufacturing Technology Degree or related field.

What is the work environment for a Barrel Rib Matting Machine Operator like?

Barrel Rib Matting Machine Operators typically work in manufacturing facilities, operating and maintaining machinery in a production environment. The work environment can be noisy and may involve working with heavy equipment.

What are the career prospects for a Barrel Rib Matting Machine Operator?

Barrel Rib Matting Machine Operators can advance to supervisory roles, such as Production Supervisor or Manufacturing Manager. With additional training or education, they may also move into engineering or quality control roles.

What is the average salary for a Barrel Rib Matting Machine Operator?

The average salary for a Barrel Rib Matting Machine Operator varies depending on location, experience, and employer. According to Indeed, the average salary in the United States is around $20 per hour.

What are the benefits of working as a Barrel Rib Matting Machine Operator?

Benefits of working as a Barrel Rib Matting Machine Operator include job stability, opportunities for advancement, and the satisfaction of working in a manufacturing environment. Additionally, many employers offer competitive benefits packages including health insurance, paid time off, and retirement plans.