Are you a seasoned Batch and Furnace Operator seeking a new career path? Discover our professionally built Batch and Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

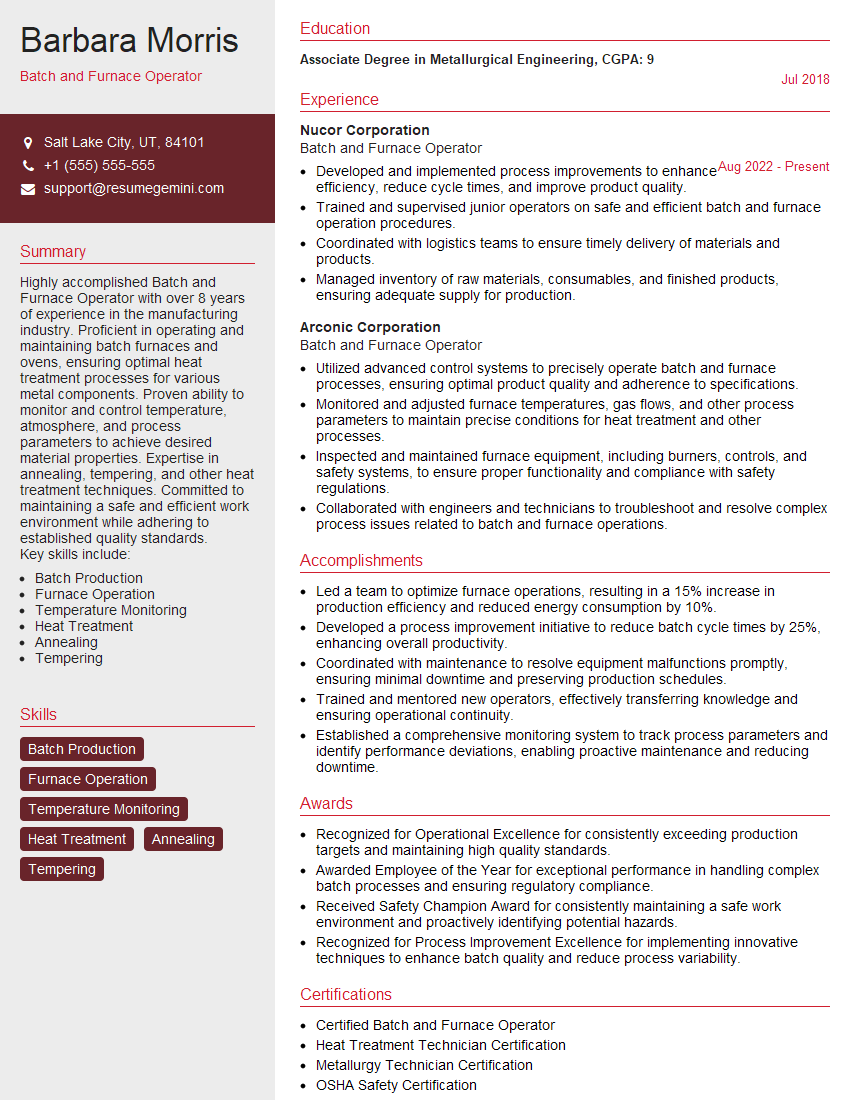

Barbara Morris

Batch and Furnace Operator

Summary

Highly accomplished Batch and Furnace Operator with over 8 years of experience in the manufacturing industry. Proficient in operating and maintaining batch furnaces and ovens, ensuring optimal heat treatment processes for various metal components. Proven ability to monitor and control temperature, atmosphere, and process parameters to achieve desired material properties. Expertise in annealing, tempering, and other heat treatment techniques. Committed to maintaining a safe and efficient work environment while adhering to established quality standards.

Key skills include:

- Batch Production

- Furnace Operation

- Temperature Monitoring

- Heat Treatment

- Annealing

- Tempering

Education

Associate Degree in Metallurgical Engineering

July 2018

Skills

- Batch Production

- Furnace Operation

- Temperature Monitoring

- Heat Treatment

- Annealing

- Tempering

Work Experience

Batch and Furnace Operator

- Developed and implemented process improvements to enhance efficiency, reduce cycle times, and improve product quality.

- Trained and supervised junior operators on safe and efficient batch and furnace operation procedures.

- Coordinated with logistics teams to ensure timely delivery of materials and products.

- Managed inventory of raw materials, consumables, and finished products, ensuring adequate supply for production.

Batch and Furnace Operator

- Utilized advanced control systems to precisely operate batch and furnace processes, ensuring optimal product quality and adherence to specifications.

- Monitored and adjusted furnace temperatures, gas flows, and other process parameters to maintain precise conditions for heat treatment and other processes.

- Inspected and maintained furnace equipment, including burners, controls, and safety systems, to ensure proper functionality and compliance with safety regulations.

- Collaborated with engineers and technicians to troubleshoot and resolve complex process issues related to batch and furnace operations.

Accomplishments

- Led a team to optimize furnace operations, resulting in a 15% increase in production efficiency and reduced energy consumption by 10%.

- Developed a process improvement initiative to reduce batch cycle times by 25%, enhancing overall productivity.

- Coordinated with maintenance to resolve equipment malfunctions promptly, ensuring minimal downtime and preserving production schedules.

- Trained and mentored new operators, effectively transferring knowledge and ensuring operational continuity.

- Established a comprehensive monitoring system to track process parameters and identify performance deviations, enabling proactive maintenance and reducing downtime.

Awards

- Recognized for Operational Excellence for consistently exceeding production targets and maintaining high quality standards.

- Awarded Employee of the Year for exceptional performance in handling complex batch processes and ensuring regulatory compliance.

- Received Safety Champion Award for consistently maintaining a safe work environment and proactively identifying potential hazards.

- Recognized for Process Improvement Excellence for implementing innovative techniques to enhance batch quality and reduce process variability.

Certificates

- Certified Batch and Furnace Operator

- Heat Treatment Technician Certification

- Metallurgy Technician Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Batch and Furnace Operator

- Highlight your experience and expertise in operating and maintaining batch furnaces and ovens.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your knowledge of heat treatment processes and techniques, including annealing, tempering, and hardening.

- Emphasize your commitment to safety and quality control, and provide examples of how you have maintained a safe and efficient work environment.

Essential Experience Highlights for a Strong Batch and Furnace Operator Resume

- Set up, operate, and maintain batch furnaces and ovens according to established procedures.

- Monitor and control temperature, atmosphere, and other process parameters to ensure optimal heat treatment conditions.

- Conduct hardness testing and other quality control checks to verify material properties meet specifications.

- Maintain and calibrate furnace equipment, including temperature sensors and controllers.

- Troubleshoot and resolve furnace malfunctions to minimize downtime and maintain production efficiency.

- Follow safety protocols and maintain a clean and organized work area.

- Work effectively as part of a team to achieve production targets and quality standards.

Frequently Asked Questions (FAQ’s) For Batch and Furnace Operator

What is the primary role of a Batch and Furnace Operator?

The primary role of a Batch and Furnace Operator is to operate and maintain batch furnaces and ovens, ensuring optimal heat treatment processes for various metal components.

What are the key skills required for a Batch and Furnace Operator?

Key skills required for a Batch and Furnace Operator include Batch Production, Furnace Operation, Temperature Monitoring, Heat Treatment, Annealing, and Tempering.

What industries typically employ Batch and Furnace Operators?

Batch and Furnace Operators are typically employed in the manufacturing industry, particularly in metalworking and heat treating facilities.

What are the career advancement opportunities for a Batch and Furnace Operator?

With experience and additional training, Batch and Furnace Operators can advance to positions such as Heat Treat Technician, Process Engineer, or Production Supervisor.

What are the safety precautions that Batch and Furnace Operators must follow?

Batch and Furnace Operators must follow established safety protocols, including wearing appropriate protective gear, handling hazardous materials safely, and maintaining a clean and organized work area.

What are the common challenges faced by Batch and Furnace Operators?

Common challenges faced by Batch and Furnace Operators include maintaining precise temperature and atmosphere control, ensuring consistent material properties, and troubleshooting furnace malfunctions.

How can I prepare for an interview for a Batch and Furnace Operator position?

To prepare for an interview for a Batch and Furnace Operator position, research common interview questions, practice answering them using specific examples from your experience, and review the company’s website and industry-related news to demonstrate your knowledge and interest in the field.