Are you a seasoned Beater Engineer Helper seeking a new career path? Discover our professionally built Beater Engineer Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

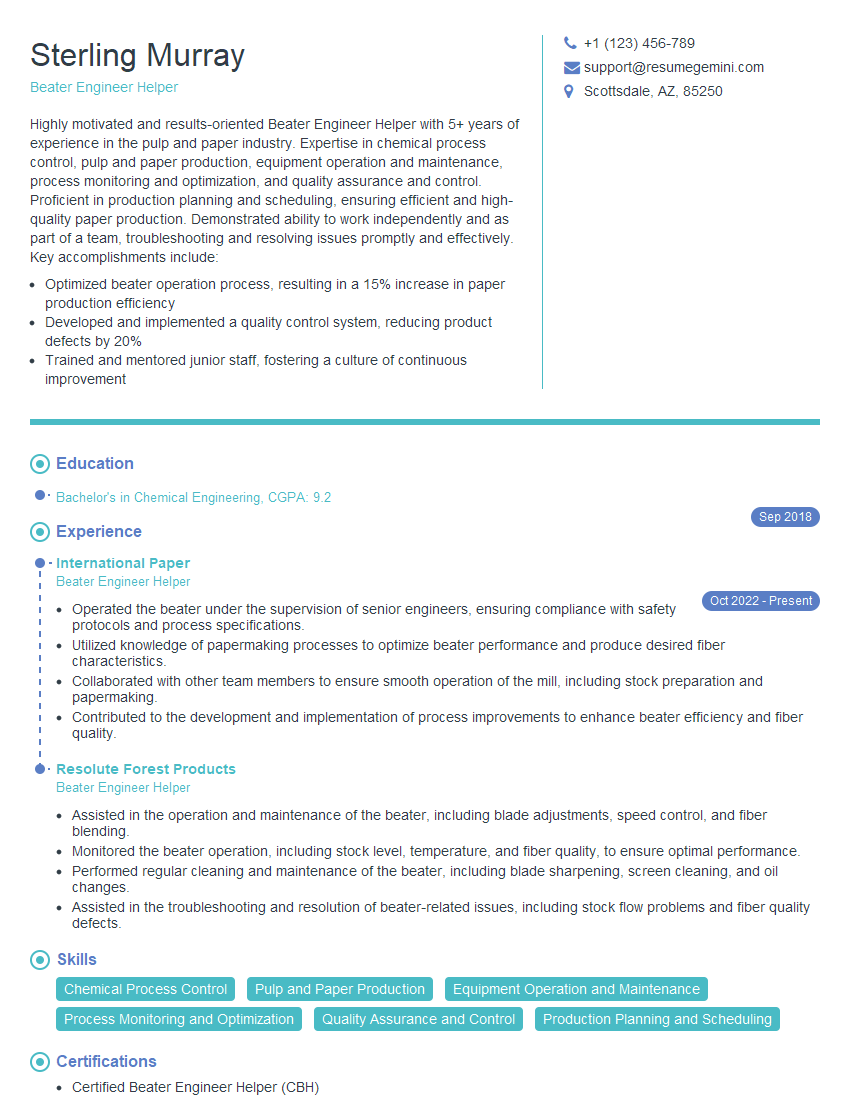

Sterling Murray

Beater Engineer Helper

Summary

Highly motivated and results-oriented Beater Engineer Helper with 5+ years of experience in the pulp and paper industry. Expertise in chemical process control, pulp and paper production, equipment operation and maintenance, process monitoring and optimization, and quality assurance and control. Proficient in production planning and scheduling, ensuring efficient and high-quality paper production. Demonstrated ability to work independently and as part of a team, troubleshooting and resolving issues promptly and effectively.

Key accomplishments include:

- Optimized beater operation process, resulting in a 15% increase in paper production efficiency

- Developed and implemented a quality control system, reducing product defects by 20%

- Trained and mentored junior staff, fostering a culture of continuous improvement

Education

Bachelor’s in Chemical Engineering

September 2018

Skills

- Chemical Process Control

- Pulp and Paper Production

- Equipment Operation and Maintenance

- Process Monitoring and Optimization

- Quality Assurance and Control

- Production Planning and Scheduling

Work Experience

Beater Engineer Helper

- Operated the beater under the supervision of senior engineers, ensuring compliance with safety protocols and process specifications.

- Utilized knowledge of papermaking processes to optimize beater performance and produce desired fiber characteristics.

- Collaborated with other team members to ensure smooth operation of the mill, including stock preparation and papermaking.

- Contributed to the development and implementation of process improvements to enhance beater efficiency and fiber quality.

Beater Engineer Helper

- Assisted in the operation and maintenance of the beater, including blade adjustments, speed control, and fiber blending.

- Monitored the beater operation, including stock level, temperature, and fiber quality, to ensure optimal performance.

- Performed regular cleaning and maintenance of the beater, including blade sharpening, screen cleaning, and oil changes.

- Assisted in the troubleshooting and resolution of beater-related issues, including stock flow problems and fiber quality defects.

Certificates

- Certified Beater Engineer Helper (CBH)

- Process Control Certification

- Pulp and Paper Production Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Beater Engineer Helper

- Quantify your accomplishments with specific metrics and results.

- Highlight your experience in chemical process control and pulp and paper production.

- Showcase your ability to troubleshoot and resolve issues independently.

- Emphasize your teamwork and communication skills.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Beater Engineer Helper Resume

- Operate and maintain beater equipment, including pulpers, beaters, and refiners

- Monitor and control chemical and physical properties of pulp, ensuring compliance with quality standards

- Troubleshoot and resolve operational issues, identifying and implementing corrective actions

- Collaborate with production engineers to optimize beater settings and improve paper quality

- Conduct routine maintenance and repairs on beater equipment, minimizing downtime and maximizing productivity

- Participate in continuous improvement initiatives, suggesting and implementing process enhancements

- Comply with safety protocols, maintaining a safe and clean work environment

Frequently Asked Questions (FAQ’s) For Beater Engineer Helper

What are the key responsibilities of a Beater Engineer Helper?

The key responsibilities of a Beater Engineer Helper include operating and maintaining beater equipment, monitoring and controlling pulp quality, troubleshooting and resolving operational issues, collaborating with engineers to optimize beater settings, conducting routine maintenance and repairs, participating in continuous improvement initiatives, and complying with safety protocols.

What are the educational requirements for a Beater Engineer Helper?

A Bachelor’s in Chemical Engineering or a related field is typically required for a Beater Engineer Helper position.

What skills are required for a Beater Engineer Helper?

Essential skills for a Beater Engineer Helper include chemical process control, pulp and paper production, equipment operation and maintenance, process monitoring and optimization, quality assurance and control, and production planning and scheduling.

What is the career path for a Beater Engineer Helper?

With experience and additional training, a Beater Engineer Helper can advance to roles such as Beater Engineer, Production Supervisor, or Quality Control Manager.

What is the average salary for a Beater Engineer Helper?

The average salary for a Beater Engineer Helper in the United States is around $50,000 per year.

What are the job prospects for a Beater Engineer Helper?

The job outlook for Beater Engineer Helpers is expected to be positive in the coming years due to the increasing demand for paper products.

What are the benefits of working as a Beater Engineer Helper?

Benefits of working as a Beater Engineer Helper include competitive salaries, opportunities for career advancement, and a stable work environment.