Are you a seasoned Beater Tender seeking a new career path? Discover our professionally built Beater Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

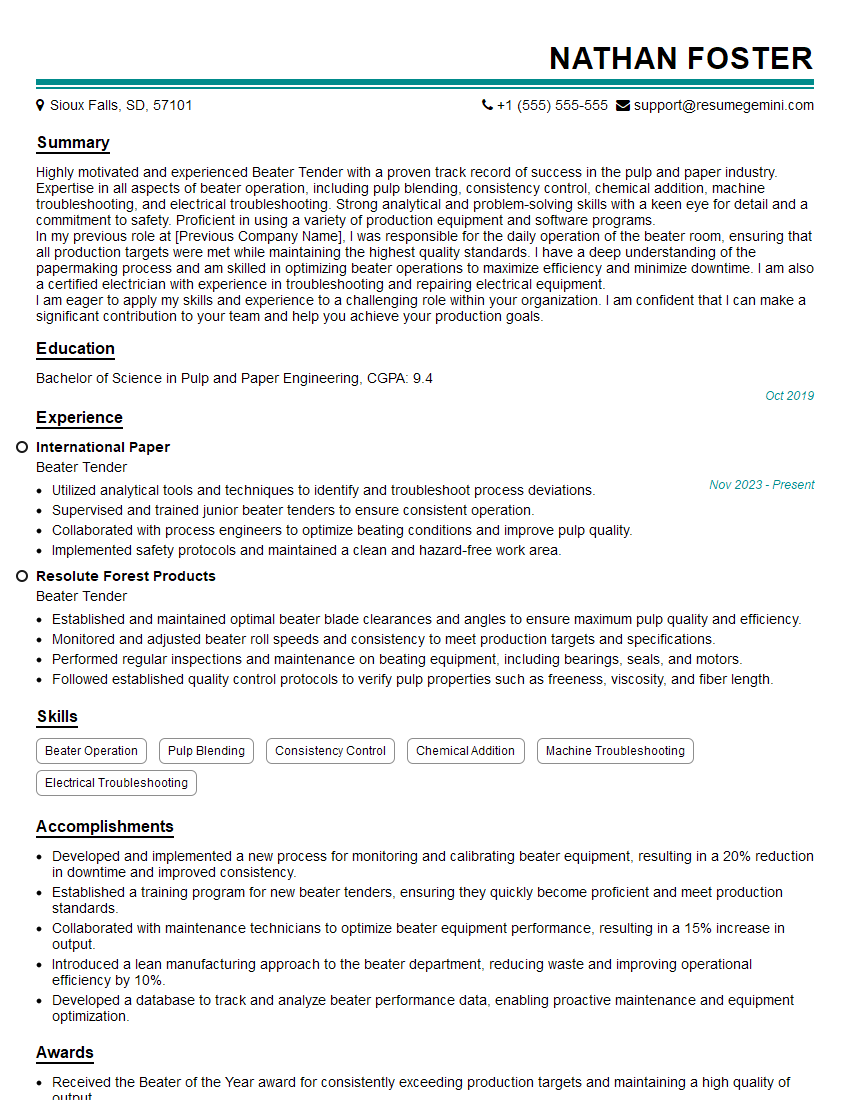

Nathan Foster

Beater Tender

Summary

Highly motivated and experienced Beater Tender with a proven track record of success in the pulp and paper industry. Expertise in all aspects of beater operation, including pulp blending, consistency control, chemical addition, machine troubleshooting, and electrical troubleshooting. Strong analytical and problem-solving skills with a keen eye for detail and a commitment to safety. Proficient in using a variety of production equipment and software programs.

In my previous role at [Previous Company Name], I was responsible for the daily operation of the beater room, ensuring that all production targets were met while maintaining the highest quality standards. I have a deep understanding of the papermaking process and am skilled in optimizing beater operations to maximize efficiency and minimize downtime. I am also a certified electrician with experience in troubleshooting and repairing electrical equipment.

I am eager to apply my skills and experience to a challenging role within your organization. I am confident that I can make a significant contribution to your team and help you achieve your production goals.

Education

Bachelor of Science in Pulp and Paper Engineering

October 2019

Skills

- Beater Operation

- Pulp Blending

- Consistency Control

- Chemical Addition

- Machine Troubleshooting

- Electrical Troubleshooting

Work Experience

Beater Tender

- Utilized analytical tools and techniques to identify and troubleshoot process deviations.

- Supervised and trained junior beater tenders to ensure consistent operation.

- Collaborated with process engineers to optimize beating conditions and improve pulp quality.

- Implemented safety protocols and maintained a clean and hazard-free work area.

Beater Tender

- Established and maintained optimal beater blade clearances and angles to ensure maximum pulp quality and efficiency.

- Monitored and adjusted beater roll speeds and consistency to meet production targets and specifications.

- Performed regular inspections and maintenance on beating equipment, including bearings, seals, and motors.

- Followed established quality control protocols to verify pulp properties such as freeness, viscosity, and fiber length.

Accomplishments

- Developed and implemented a new process for monitoring and calibrating beater equipment, resulting in a 20% reduction in downtime and improved consistency.

- Established a training program for new beater tenders, ensuring they quickly become proficient and meet production standards.

- Collaborated with maintenance technicians to optimize beater equipment performance, resulting in a 15% increase in output.

- Introduced a lean manufacturing approach to the beater department, reducing waste and improving operational efficiency by 10%.

- Developed a database to track and analyze beater performance data, enabling proactive maintenance and equipment optimization.

Awards

- Received the Beater of the Year award for consistently exceeding production targets and maintaining a high quality of output.

- Recognized for outstanding safety performance for working over 1,000 consecutive days without any accidents or incidents.

- Received the Productivity Star award for maintaining a production efficiency rate of over 95% for an extended period.

- Won the Safety Champion award for actively promoting safety awareness and reporting potential hazards.

Certificates

- American Pulp and Paper Association (APPA) Beater Tender Certification

- Technical Association of the Pulp and Paper Industry (TAPPI) Beater Tender Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Beater Tender

- Highlight your experience in operating beater equipment and controlling pulp properties.

- Showcase your troubleshooting and problem-solving skills, providing specific examples of how you resolved issues.

- Quantify your accomplishments, using metrics to demonstrate the impact of your work.

- Tailor your resume to the specific requirements of the job you are applying for.

- Proofread your resume carefully before submitting it to ensure that it is error-free and well-written.

Essential Experience Highlights for a Strong Beater Tender Resume

- Operate beater equipment to blend and refine pulp according to production specifications.

- Control pulp consistency and add chemicals to achieve desired pulp properties.

- Troubleshoot and resolve machine malfunctions to maintain optimal production levels.

- Conduct routine maintenance and repairs on beater equipment to ensure smooth operation.

- Monitor production data and make adjustments to optimize beater performance.

- Adhere to safety regulations and maintain a clean and organized work environment.

- Collaborate with other team members to ensure efficient and coordinated production.

Frequently Asked Questions (FAQ’s) For Beater Tender

What is the primary role of a beater tender?

The primary role of a beater tender is to operate and maintain beater equipment used in the pulp and paper industry. They are responsible for blending and refining pulp, controlling pulp consistency, adding chemicals, troubleshooting machine malfunctions, and conducting routine maintenance.

What are the key skills required to be a successful beater tender?

Key skills for a successful beater tender include experience in operating beater equipment, controlling pulp properties, troubleshooting and problem-solving, conducting maintenance and repairs, monitoring production data, adhering to safety regulations, and collaborating with others.

What type of education and training is required to become a beater tender?

While there are no specific educational requirements for beater tenders, many employers prefer candidates with a high school diploma or equivalent. Some beater tenders may have a bachelor’s degree in a related field, such as pulp and paper engineering or chemical engineering.

What are the career prospects for beater tenders?

Experienced beater tenders may advance to supervisory roles, such as beater room supervisor or production manager. With additional training and experience, some beater tenders may also pursue careers in quality control or research and development.

What is the work environment like for beater tenders?

Beater tenders typically work in a manufacturing environment, such as a paper mill or pulp mill. They may work in teams or independently, and may be exposed to noise, dust, and chemicals.

What are the safety hazards associated with being a beater tender?

Safety hazards associated with being a beater tender include exposure to moving machinery, sharp objects, and chemicals. They may also be required to work in confined spaces or at heights.

What are the key challenges faced by beater tenders?

Key challenges faced by beater tenders include maintaining optimal beater performance, troubleshooting and resolving machine malfunctions, and ensuring the production of high-quality pulp. They must also be able to work effectively in a fast-paced and demanding environment.

What is the average salary for beater tenders?

The average salary for beater tenders can vary depending on factors such as experience, location, and employer. According to Salary.com, the average salary for beater tenders in the United States is around $55,000 per year.