Are you a seasoned Belt Splicer seeking a new career path? Discover our professionally built Belt Splicer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

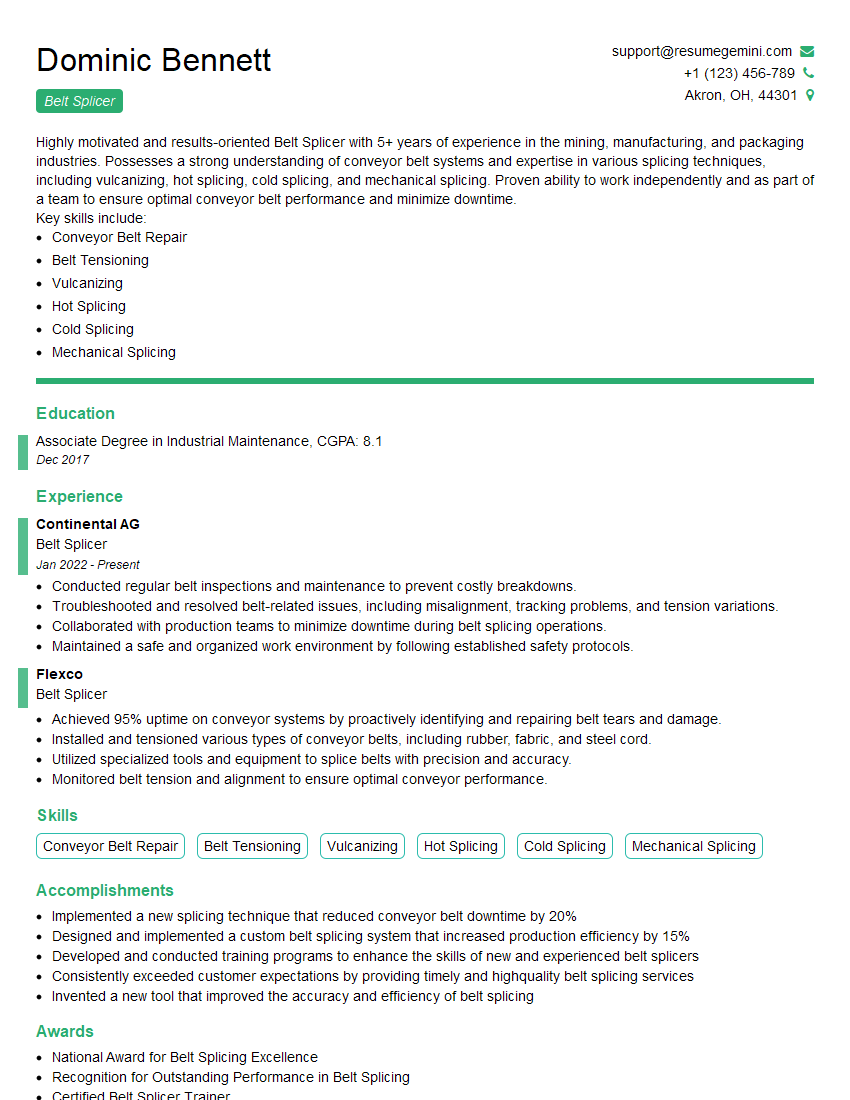

Dominic Bennett

Belt Splicer

Summary

Highly motivated and results-oriented Belt Splicer with 5+ years of experience in the mining, manufacturing, and packaging industries. Possesses a strong understanding of conveyor belt systems and expertise in various splicing techniques, including vulcanizing, hot splicing, cold splicing, and mechanical splicing. Proven ability to work independently and as part of a team to ensure optimal conveyor belt performance and minimize downtime.

Key skills include:

- Conveyor Belt Repair

- Belt Tensioning

- Vulcanizing

- Hot Splicing

- Cold Splicing

- Mechanical Splicing

Education

Associate Degree in Industrial Maintenance

December 2017

Skills

- Conveyor Belt Repair

- Belt Tensioning

- Vulcanizing

- Hot Splicing

- Cold Splicing

- Mechanical Splicing

Work Experience

Belt Splicer

- Conducted regular belt inspections and maintenance to prevent costly breakdowns.

- Troubleshooted and resolved belt-related issues, including misalignment, tracking problems, and tension variations.

- Collaborated with production teams to minimize downtime during belt splicing operations.

- Maintained a safe and organized work environment by following established safety protocols.

Belt Splicer

- Achieved 95% uptime on conveyor systems by proactively identifying and repairing belt tears and damage.

- Installed and tensioned various types of conveyor belts, including rubber, fabric, and steel cord.

- Utilized specialized tools and equipment to splice belts with precision and accuracy.

- Monitored belt tension and alignment to ensure optimal conveyor performance.

Accomplishments

- Implemented a new splicing technique that reduced conveyor belt downtime by 20%

- Designed and implemented a custom belt splicing system that increased production efficiency by 15%

- Developed and conducted training programs to enhance the skills of new and experienced belt splicers

- Consistently exceeded customer expectations by providing timely and highquality belt splicing services

- Invented a new tool that improved the accuracy and efficiency of belt splicing

Awards

- National Award for Belt Splicing Excellence

- Recognition for Outstanding Performance in Belt Splicing

- Certified Belt Splicer Trainer

- Award for Exceptional Customer Service

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Belt Splicer

- Highlight your experience with specific splicing techniques, especially those relevant to the industry you’re applying to.

- Quantify your accomplishments whenever possible, using metrics like downtime reduction or increased production efficiency.

- Showcase your knowledge of conveyor belt systems and industry best practices.

- Emphasize your ability to work independently and as part of a team.

- Consider including a portfolio of your splicing work to demonstrate your skills.

Essential Experience Highlights for a Strong Belt Splicer Resume

- Inspect and assess conveyor belt systems to identify areas of damage or wear.

- Select and implement appropriate splicing techniques based on belt type, operating conditions, and repair requirements.

- Prepare belt surfaces, clean and prepare splicing materials, and operate splicing equipment to join belt edges.

- Test and tension splices to ensure proper adhesion and performance.

- Maintain a clean and organized work area, and adhere to safety protocols.

- Train and supervise junior belt splicers, and provide technical guidance to maintenance personnel.

- Troubleshoot and resolve conveyor belt issues, and recommend preventive maintenance strategies.

Frequently Asked Questions (FAQ’s) For Belt Splicer

What are the different types of belt splicing techniques?

The most common belt splicing techniques include vulcanizing, hot splicing, cold splicing, and mechanical splicing. Vulcanizing involves using heat and pressure to bond the belt edges together, while hot splicing uses a heated press to fuse the belt materials. Cold splicing utilizes chemical adhesives to join the belt edges, and mechanical splicing employs fasteners or clamps to hold the belt together.

What are the key skills required for a successful belt splicer?

Successful belt splicers typically possess a strong understanding of conveyor belt systems, expertise in various splicing techniques, and proficiency in using splicing equipment. They are also physically fit and able to work in demanding environments. Additionally, effective communication and teamwork skills are essential for collaborating with maintenance personnel and resolving conveyor belt issues.

What industries utilize belt splicers?

Belt splicers are employed in a wide range of industries that rely on conveyor belt systems, including mining, manufacturing, packaging, and transportation. They play a crucial role in maintaining optimal conveyor belt performance and minimizing downtime, ensuring the smooth operation of production lines and efficient material handling.

How can I advance my career as a belt splicer?

To advance your career as a belt splicer, consider pursuing professional development opportunities such as workshops, training programs, or certifications. Staying updated with the latest industry best practices and technologies can enhance your skills and credibility. Seeking leadership roles or mentoring junior splicers can also contribute to your professional growth.

What are the safety precautions that belt splicers should observe?

Belt splicers must prioritize safety by wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection. They should be trained on proper splicing techniques and equipment operation to minimize risks. Regular inspections and maintenance of splicing equipment are also essential to ensure safety and prevent accidents.