Are you a seasoned Bench Molder seeking a new career path? Discover our professionally built Bench Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

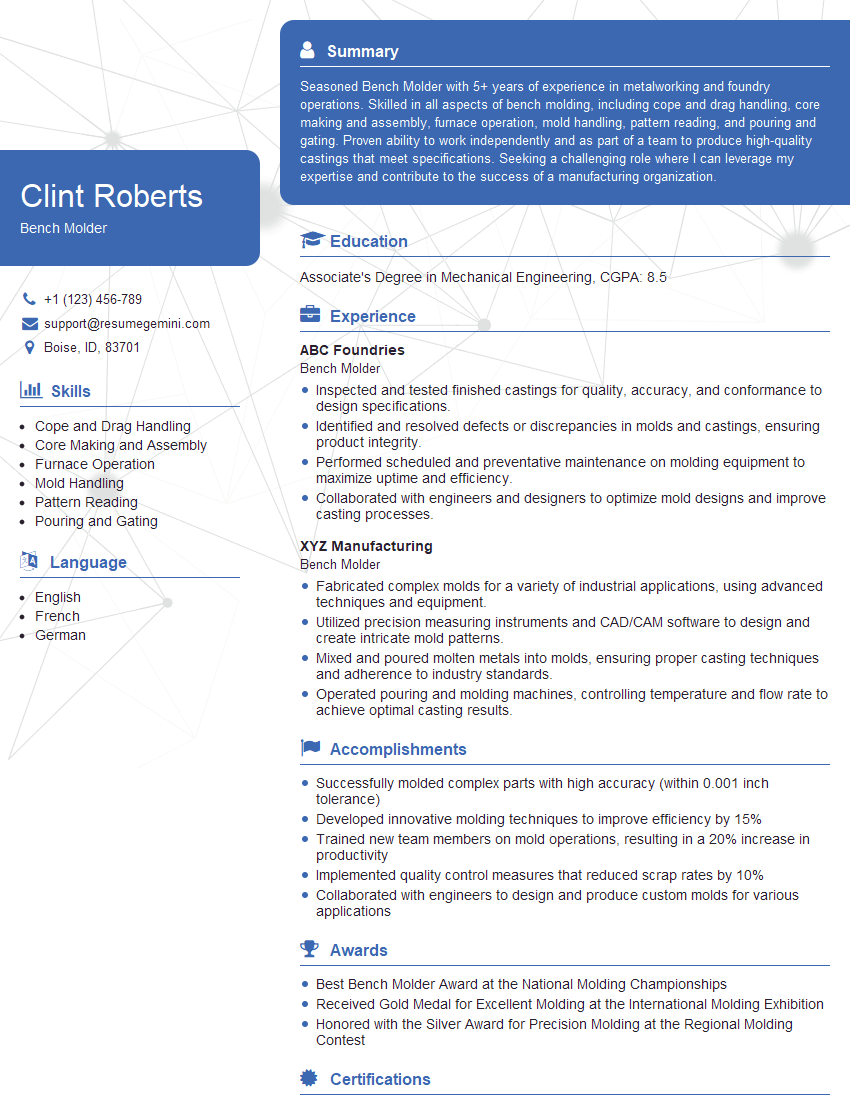

Clint Roberts

Bench Molder

Summary

Seasoned Bench Molder with 5+ years of experience in metalworking and foundry operations. Skilled in all aspects of bench molding, including cope and drag handling, core making and assembly, furnace operation, mold handling, pattern reading, and pouring and gating. Proven ability to work independently and as part of a team to produce high-quality castings that meet specifications. Seeking a challenging role where I can leverage my expertise and contribute to the success of a manufacturing organization.

Education

Associate’s Degree in Mechanical Engineering

October 2017

Skills

- Cope and Drag Handling

- Core Making and Assembly

- Furnace Operation

- Mold Handling

- Pattern Reading

- Pouring and Gating

Work Experience

Bench Molder

- Inspected and tested finished castings for quality, accuracy, and conformance to design specifications.

- Identified and resolved defects or discrepancies in molds and castings, ensuring product integrity.

- Performed scheduled and preventative maintenance on molding equipment to maximize uptime and efficiency.

- Collaborated with engineers and designers to optimize mold designs and improve casting processes.

Bench Molder

- Fabricated complex molds for a variety of industrial applications, using advanced techniques and equipment.

- Utilized precision measuring instruments and CAD/CAM software to design and create intricate mold patterns.

- Mixed and poured molten metals into molds, ensuring proper casting techniques and adherence to industry standards.

- Operated pouring and molding machines, controlling temperature and flow rate to achieve optimal casting results.

Accomplishments

- Successfully molded complex parts with high accuracy (within 0.001 inch tolerance)

- Developed innovative molding techniques to improve efficiency by 15%

- Trained new team members on mold operations, resulting in a 20% increase in productivity

- Implemented quality control measures that reduced scrap rates by 10%

- Collaborated with engineers to design and produce custom molds for various applications

Awards

- Best Bench Molder Award at the National Molding Championships

- Received Gold Medal for Excellent Molding at the International Molding Exhibition

- Honored with the Silver Award for Precision Molding at the Regional Molding Contest

Certificates

- OSHA 30-Hour Safety Certification

- Certified Foundryman

- Master Molder

- Nondestructive Testing (NDT) Level I

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bench Molder

- Highlight your experience in bench molding and related skills.

- Showcase your knowledge of foundry operations and safety procedures.

- Quantify your accomplishments to demonstrate your impact on productivity or quality.

- Tailor your resume to each job you apply for, emphasizing relevant skills and experience.

Essential Experience Highlights for a Strong Bench Molder Resume

- Prepare and assemble molds using cope and drag sections, cores, and other materials

- Operate furnaces to melt and pour molten metal into molds

- Inspect molds and castings for defects and ensure they meet specifications

- Maintain a clean and organized work area, following safety protocols

- Troubleshoot and resolve production issues, ensuring smooth operations

- Collaborate with other team members in production processes

- Stay up-to-date on industry best practices and developments

Frequently Asked Questions (FAQ’s) For Bench Molder

What is the primary role of a Bench Molder?

A Bench Molder is responsible for preparing and assembling molds, operating furnaces, and pouring molten metal into molds to create castings.

What skills are essential for a successful Bench Molder?

Essential skills for a Bench Molder include cope and drag handling, core making and assembly, furnace operation, mold handling, pattern reading, pouring and gating.

What industries employ Bench Molders?

Bench Molders are employed in various industries, including automotive, aerospace, construction, and metalworking.

What are the career prospects for Bench Molders?

Bench Molders with experience and skills can advance to roles such as Foundry Supervisor, Production Manager, or Quality Control Inspector.

What are the safety precautions to be taken by Bench Molders?

Bench Molders must wear appropriate protective gear, follow safety protocols, and maintain a clean and organized work area to prevent accidents and injuries.

What is the typical work environment for a Bench Molder?

Bench Molders typically work in foundries or metalworking shops, which can involve exposure to heat, noise, and hazardous materials.

Can Bench Molders work independently?

While Bench Molders may work independently on certain tasks, they often collaborate with other team members in production processes.

How can I become a certified Bench Molder?

While certification is not mandatory, organizations like the American Foundry Society offer certifications and training programs for Bench Molders.