Are you a seasoned Bevel Face Stoner and Polisher seeking a new career path? Discover our professionally built Bevel Face Stoner and Polisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

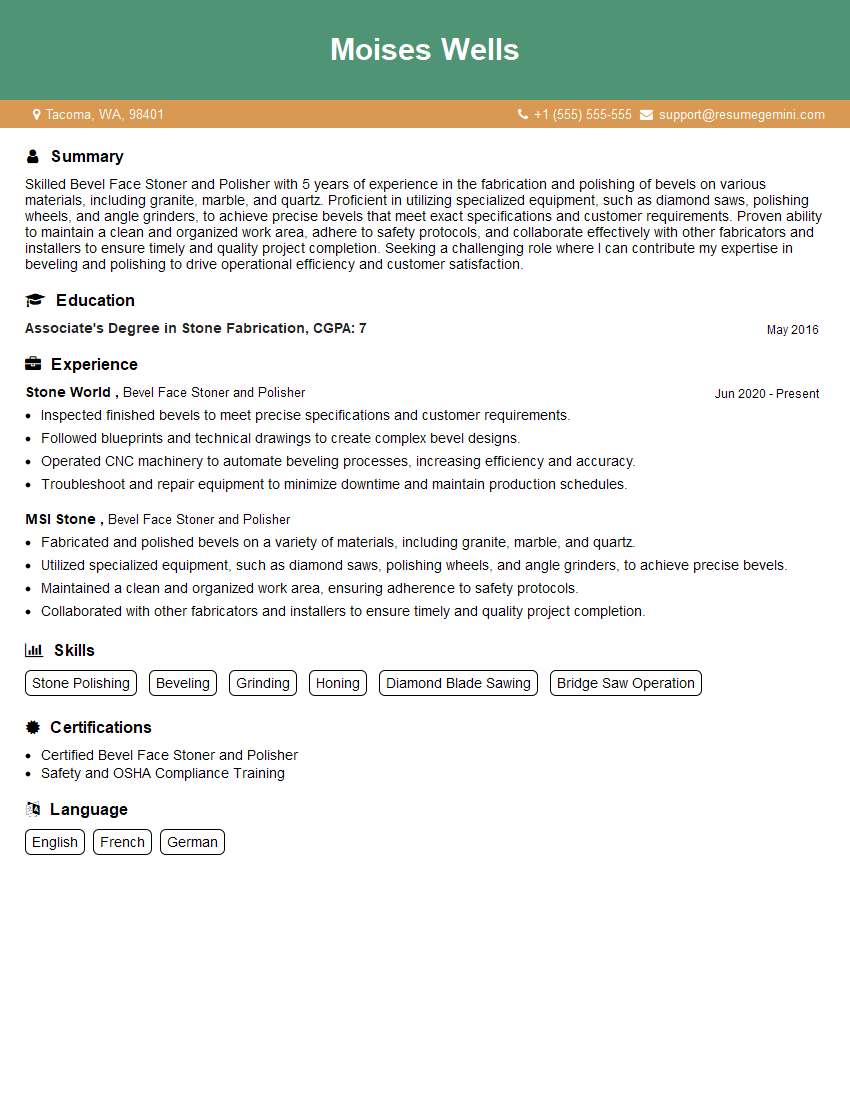

Moises Wells

Bevel Face Stoner and Polisher

Summary

Skilled Bevel Face Stoner and Polisher with 5 years of experience in the fabrication and polishing of bevels on various materials, including granite, marble, and quartz. Proficient in utilizing specialized equipment, such as diamond saws, polishing wheels, and angle grinders, to achieve precise bevels that meet exact specifications and customer requirements. Proven ability to maintain a clean and organized work area, adhere to safety protocols, and collaborate effectively with other fabricators and installers to ensure timely and quality project completion. Seeking a challenging role where I can contribute my expertise in beveling and polishing to drive operational efficiency and customer satisfaction.

Education

Associate’s Degree in Stone Fabrication

May 2016

Skills

- Stone Polishing

- Beveling

- Grinding

- Honing

- Diamond Blade Sawing

- Bridge Saw Operation

Work Experience

Bevel Face Stoner and Polisher

- Inspected finished bevels to meet precise specifications and customer requirements.

- Followed blueprints and technical drawings to create complex bevel designs.

- Operated CNC machinery to automate beveling processes, increasing efficiency and accuracy.

- Troubleshoot and repair equipment to minimize downtime and maintain production schedules.

Bevel Face Stoner and Polisher

- Fabricated and polished bevels on a variety of materials, including granite, marble, and quartz.

- Utilized specialized equipment, such as diamond saws, polishing wheels, and angle grinders, to achieve precise bevels.

- Maintained a clean and organized work area, ensuring adherence to safety protocols.

- Collaborated with other fabricators and installers to ensure timely and quality project completion.

Certificates

- Certified Bevel Face Stoner and Polisher

- Safety and OSHA Compliance Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bevel Face Stoner and Polisher

- Highlight your expertise in beveling techniques and the use of specialized equipment, showcasing your proficiency in this specialized field.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work on project outcomes, such as increased efficiency, reduced production time, or improved customer satisfaction.

- Include relevant certifications or training programs that demonstrate your commitment to professional development and staying up-to-date with industry best practices.

- Tailor your resume to each specific job application, emphasizing the skills and experience that most closely align with the requirements of the position you are seeking.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Bevel Face Stoner and Polisher Resume

- Fabricate and polish bevels on a variety of materials, including granite, marble, and quartz, to precise specifications and customer requirements.

- Utilize specialized equipment, such as diamond saws, polishing wheels, and angle grinders, to achieve desired bevel designs and surface finishes.

- Maintain a clean and organized work area, ensuring adherence to safety protocols and industry best practices.

- Collaborate with other fabricators and installers to ensure timely and quality project completion, contributing to overall operational efficiency.

- Inspect finished bevels to ensure they meet precise specifications and customer requirements, maintaining high standards of quality control.

- Follow blueprints and technical drawings to create complex bevel designs, demonstrating strong attention to detail and technical proficiency.

- Operate CNC machinery to automate beveling processes, increasing efficiency and accuracy in production, while minimizing manual labor and reducing production time.

Frequently Asked Questions (FAQ’s) For Bevel Face Stoner and Polisher

What are the key skills required for a Bevel Face Stoner and Polisher?

The key skills required for a Bevel Face Stoner and Polisher include stone polishing, beveling, grinding, honing, diamond blade sawing, and bridge saw operation.

What are the primary responsibilities of a Bevel Face Stoner and Polisher?

The primary responsibilities of a Bevel Face Stoner and Polisher include fabricating and polishing bevels on various materials, utilizing specialized equipment to achieve precise bevels, maintaining a clean and organized work area, collaborating with other fabricators and installers to ensure timely project completion, and inspecting finished bevels to meet precise specifications and customer requirements.

What are the educational qualifications required to become a Bevel Face Stoner and Polisher?

While there are no specific educational requirements to become a Bevel Face Stoner and Polisher, many employers prefer candidates with an Associate’s Degree in Stone Fabrication or a related field.

What are the career prospects for a Bevel Face Stoner and Polisher?

With experience and additional training, a Bevel Face Stoner and Polisher can advance to supervisory or management positions, or they can specialize in specific areas of stone fabrication, such as CNC programming or automated beveling systems.

What is the job outlook for Bevel Face Stoners and Polishers?

The job outlook for Bevel Face Stoners and Polishers is expected to grow in the coming years, driven by the increasing demand for natural stone products in construction and renovation projects.

What are the key qualities of a successful Bevel Face Stoner and Polisher?

The key qualities of a successful Bevel Face Stoner and Polisher include attention to detail, precision, and a strong work ethic. They should also be able to work independently and as part of a team, and they should have a good understanding of stone fabrication techniques.

What are the challenges faced by Bevel Face Stoners and Polishers?

The challenges faced by Bevel Face Stoners and Polishers include working with heavy materials, exposure to dust and noise, and the need to meet tight deadlines.

What are the safety precautions that Bevel Face Stoners and Polishers should take?

The safety precautions that Bevel Face Stoners and Polishers should take include wearing protective clothing and respirators, using sharp tools carefully, and being aware of their surroundings.