Are you a seasoned Bevel Operator seeking a new career path? Discover our professionally built Bevel Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

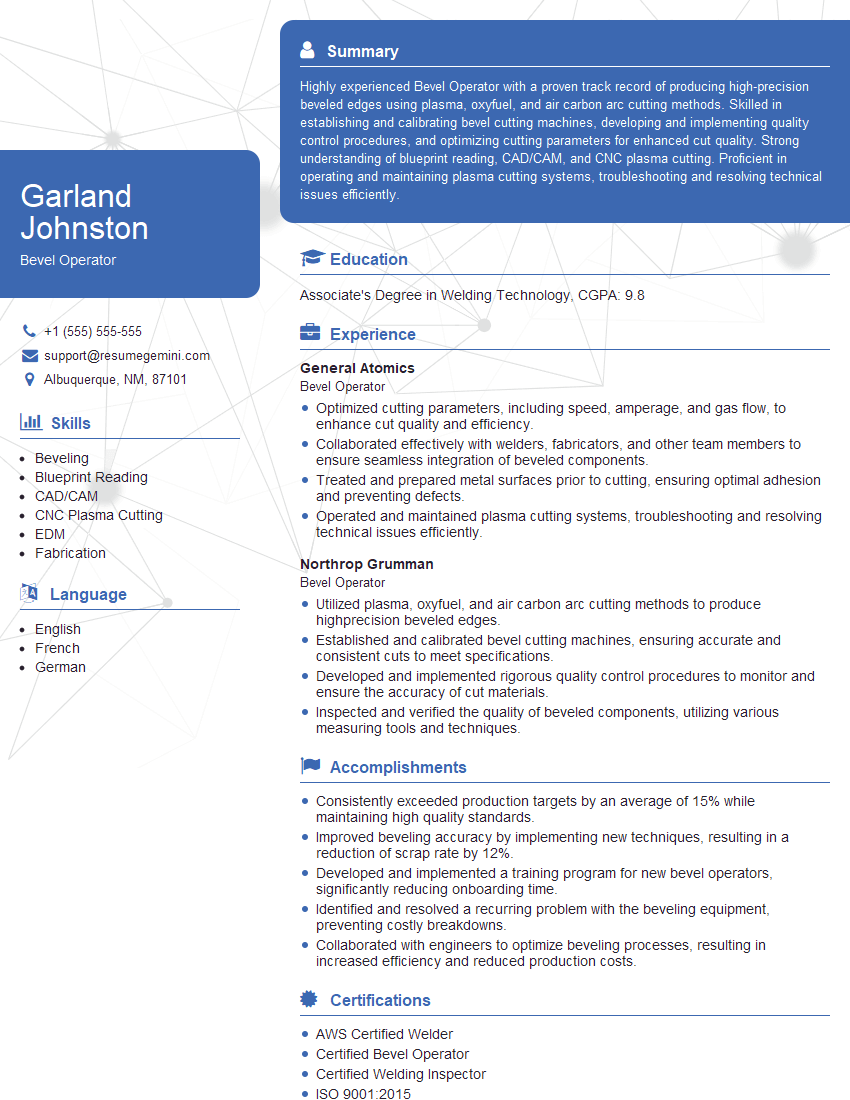

Garland Johnston

Bevel Operator

Summary

Highly experienced Bevel Operator with a proven track record of producing high-precision beveled edges using plasma, oxyfuel, and air carbon arc cutting methods. Skilled in establishing and calibrating bevel cutting machines, developing and implementing quality control procedures, and optimizing cutting parameters for enhanced cut quality. Strong understanding of blueprint reading, CAD/CAM, and CNC plasma cutting. Proficient in operating and maintaining plasma cutting systems, troubleshooting and resolving technical issues efficiently.

Education

Associate’s Degree in Welding Technology

April 2019

Skills

- Beveling

- Blueprint Reading

- CAD/CAM

- CNC Plasma Cutting

- EDM

- Fabrication

Work Experience

Bevel Operator

- Optimized cutting parameters, including speed, amperage, and gas flow, to enhance cut quality and efficiency.

- Collaborated effectively with welders, fabricators, and other team members to ensure seamless integration of beveled components.

- Treated and prepared metal surfaces prior to cutting, ensuring optimal adhesion and preventing defects.

- Operated and maintained plasma cutting systems, troubleshooting and resolving technical issues efficiently.

Bevel Operator

- Utilized plasma, oxyfuel, and air carbon arc cutting methods to produce highprecision beveled edges.

- Established and calibrated bevel cutting machines, ensuring accurate and consistent cuts to meet specifications.

- Developed and implemented rigorous quality control procedures to monitor and ensure the accuracy of cut materials.

- Inspected and verified the quality of beveled components, utilizing various measuring tools and techniques.

Accomplishments

- Consistently exceeded production targets by an average of 15% while maintaining high quality standards.

- Improved beveling accuracy by implementing new techniques, resulting in a reduction of scrap rate by 12%.

- Developed and implemented a training program for new bevel operators, significantly reducing onboarding time.

- Identified and resolved a recurring problem with the beveling equipment, preventing costly breakdowns.

- Collaborated with engineers to optimize beveling processes, resulting in increased efficiency and reduced production costs.

Certificates

- AWS Certified Welder

- Certified Bevel Operator

- Certified Welding Inspector

- ISO 9001:2015

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bevel Operator

- Highlight your experience and skills in plasma, oxyfuel, and air carbon arc cutting methods.

- Emphasize your ability to establish and calibrate bevel cutting machines to produce high-precision cuts.

- Showcase your knowledge of blueprint reading, CAD/CAM, and CNC plasma cutting.

- Provide examples of how you have optimized cutting parameters to enhance cut quality and efficiency.

- Include keywords related to the industry, such as ‘beveling,’ ‘plasma cutting,’ ‘quality control,’ and ‘fabrication.’

Essential Experience Highlights for a Strong Bevel Operator Resume

- Utilized plasma, oxyfuel, and air carbon arc cutting methods to produce high-precision beveled edges.

- Established and calibrated bevel cutting machines, ensuring accurate and consistent cuts to meet specifications.

- Developed and implemented rigorous quality control procedures to monitor and ensure the accuracy of cut materials.

- Inspected and verified the quality of beveled components, utilizing various measuring tools and techniques.

- Optimized cutting parameters, including speed, amperage, and gas flow, to enhance cut quality and efficiency.

- Collaborated effectively with welders, fabricators, and other team members to ensure seamless integration of beveled components.

Frequently Asked Questions (FAQ’s) For Bevel Operator

What are the primary responsibilities of a Bevel Operator?

Bevel Operators are responsible for producing high-precision beveled edges using various cutting methods. They establish and calibrate bevel cutting machines, implement quality control procedures, inspect and verify the quality of cut materials, and optimize cutting parameters for enhanced quality and efficiency.

What are the different cutting methods used by Bevel Operators?

Bevel Operators utilize plasma, oxyfuel, and air carbon arc cutting methods to produce beveled edges.

What skills are essential for a successful Bevel Operator?

Successful Bevel Operators possess skills in blueprint reading, CAD/CAM, CNC plasma cutting, and fabrication. They are proficient in operating and maintaining plasma cutting systems and have a strong understanding of quality control procedures.

What industries employ Bevel Operators?

Bevel Operators are employed in various industries, including manufacturing, fabrication, shipbuilding, and construction.

What are the career advancement opportunities for Bevel Operators?

Bevel Operators can advance their careers by becoming supervisors, quality control inspectors, or welding engineers. They can also specialize in specific cutting methods or industries.

What is the job outlook for Bevel Operators?

The job outlook for Bevel Operators is expected to be stable, with a projected average growth of 4% from 2022 to 2032.