Are you a seasoned Bevel Polisher seeking a new career path? Discover our professionally built Bevel Polisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

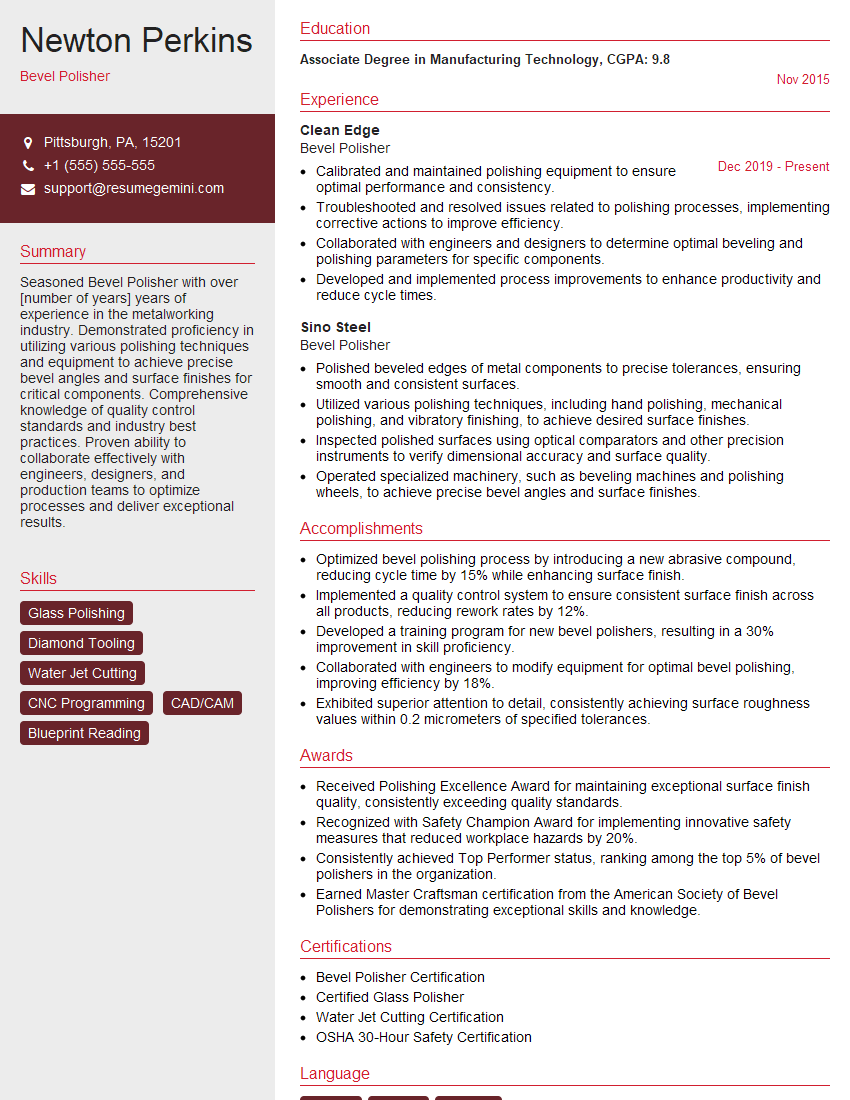

Newton Perkins

Bevel Polisher

Summary

Seasoned Bevel Polisher with over [number of years] years of experience in the metalworking industry. Demonstrated proficiency in utilizing various polishing techniques and equipment to achieve precise bevel angles and surface finishes for critical components. Comprehensive knowledge of quality control standards and industry best practices. Proven ability to collaborate effectively with engineers, designers, and production teams to optimize processes and deliver exceptional results.

Education

Associate Degree in Manufacturing Technology

November 2015

Skills

- Glass Polishing

- Diamond Tooling

- Water Jet Cutting

- CNC Programming

- CAD/CAM

- Blueprint Reading

Work Experience

Bevel Polisher

- Calibrated and maintained polishing equipment to ensure optimal performance and consistency.

- Troubleshooted and resolved issues related to polishing processes, implementing corrective actions to improve efficiency.

- Collaborated with engineers and designers to determine optimal beveling and polishing parameters for specific components.

- Developed and implemented process improvements to enhance productivity and reduce cycle times.

Bevel Polisher

- Polished beveled edges of metal components to precise tolerances, ensuring smooth and consistent surfaces.

- Utilized various polishing techniques, including hand polishing, mechanical polishing, and vibratory finishing, to achieve desired surface finishes.

- Inspected polished surfaces using optical comparators and other precision instruments to verify dimensional accuracy and surface quality.

- Operated specialized machinery, such as beveling machines and polishing wheels, to achieve precise bevel angles and surface finishes.

Accomplishments

- Optimized bevel polishing process by introducing a new abrasive compound, reducing cycle time by 15% while enhancing surface finish.

- Implemented a quality control system to ensure consistent surface finish across all products, reducing rework rates by 12%.

- Developed a training program for new bevel polishers, resulting in a 30% improvement in skill proficiency.

- Collaborated with engineers to modify equipment for optimal bevel polishing, improving efficiency by 18%.

- Exhibited superior attention to detail, consistently achieving surface roughness values within 0.2 micrometers of specified tolerances.

Awards

- Received Polishing Excellence Award for maintaining exceptional surface finish quality, consistently exceeding quality standards.

- Recognized with Safety Champion Award for implementing innovative safety measures that reduced workplace hazards by 20%.

- Consistently achieved Top Performer status, ranking among the top 5% of bevel polishers in the organization.

- Earned Master Craftsman certification from the American Society of Bevel Polishers for demonstrating exceptional skills and knowledge.

Certificates

- Bevel Polisher Certification

- Certified Glass Polisher

- Water Jet Cutting Certification

- OSHA 30-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bevel Polisher

- Highlight your technical skills: Emphasize your proficiency in specific polishing techniques, machinery, and quality control methods.

- Showcase your attention to detail: Bevel polishing requires precision and accuracy; highlight your ability to meet exacting specifications and tolerances.

- Quantify your accomplishments: If possible, provide specific numbers or metrics to demonstrate the impact of your work, such as improvements in surface finish quality or reduced cycle times.

- Showcase your problem-solving abilities: Bevel polishing can involve troubleshooting and resolving issues; highlight your analytical skills and ability to find effective solutions.

- Get certified: Consider obtaining industry-recognized certifications in bevel polishing or related fields to enhance your credibility and demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Bevel Polisher Resume

- Polished beveled edges of metal components to precise tolerances, ensuring smooth and consistent surfaces.

- Utilized various polishing techniques, including hand polishing, mechanical polishing, and vibratory finishing, to achieve desired surface finishes.

- Inspected polished surfaces using optical comparators and other precision instruments to verify dimensional accuracy and surface quality.

- Operated specialized machinery, such as beveling machines and polishing wheels, to achieve precise bevel angles and surface finishes.

- Calibrated and maintained polishing equipment to ensure optimal performance and consistency.

- Troubleshooted and resolved issues related to polishing processes, implementing corrective actions to improve efficiency.

- Collaborated with engineers and designers to determine optimal beveling and polishing parameters for specific components.

- Developed and implemented process improvements to enhance productivity and reduce cycle times.

Frequently Asked Questions (FAQ’s) For Bevel Polisher

What are the essential skills for a Bevel Polisher?

Essential skills include proficiency in various polishing techniques, machine operation, quality control, and attention to detail.

What industries employ Bevel Polishers?

Bevel Polishers are employed in a range of industries, including aerospace, automotive, manufacturing, and medical device manufacturing.

What are the career advancement opportunities for Bevel Polishers?

With experience and additional qualifications, Bevel Polishers can advance to roles such as Quality Inspector, Process Engineer, or Production Supervisor.

What is the work environment of a Bevel Polisher like?

Bevel Polishers typically work in manufacturing or industrial settings, often involving exposure to noise and dust.

Is there a high demand for Bevel Polishers?

The demand for Bevel Polishers varies depending on industry and economic conditions, but skilled professionals with specialized expertise are generally in demand.

Can a Bevel Polisher work independently?

While Bevel Polishers often work as part of a team, they may also be required to work independently, following detailed instructions and specifications.

What are the safety precautions for Bevel Polishers?

Safety precautions include wearing appropriate protective gear, following proper machine operation procedures, and ensuring adequate ventilation.

What is the salary range for Bevel Polishers?

The salary range for Bevel Polishers varies based on experience, location, and industry, but typically falls within the range of [salary range].