Are you a seasoned Beveling and Edging Machine Operator Helper seeking a new career path? Discover our professionally built Beveling and Edging Machine Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

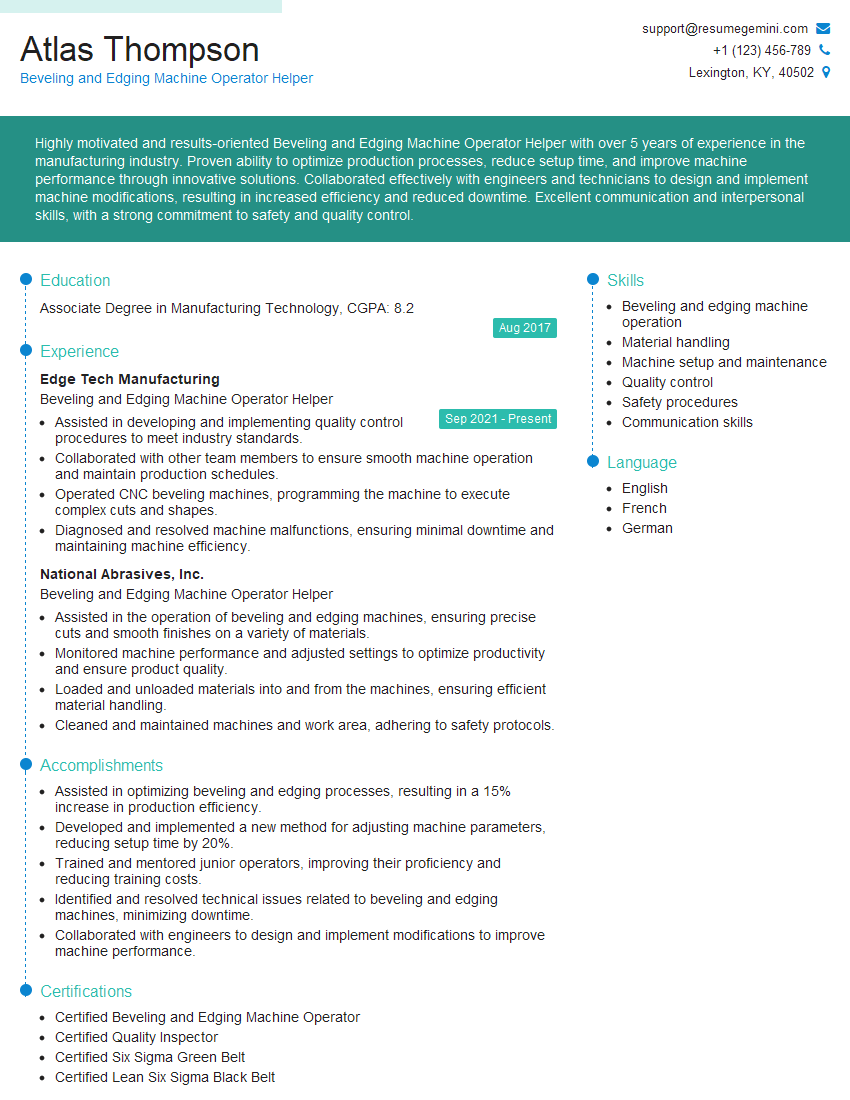

Atlas Thompson

Beveling and Edging Machine Operator Helper

Summary

Highly motivated and results-oriented Beveling and Edging Machine Operator Helper with over 5 years of experience in the manufacturing industry. Proven ability to optimize production processes, reduce setup time, and improve machine performance through innovative solutions. Collaborated effectively with engineers and technicians to design and implement machine modifications, resulting in increased efficiency and reduced downtime. Excellent communication and interpersonal skills, with a strong commitment to safety and quality control.

Education

Associate Degree in Manufacturing Technology

August 2017

Skills

- Beveling and edging machine operation

- Material handling

- Machine setup and maintenance

- Quality control

- Safety procedures

- Communication skills

Work Experience

Beveling and Edging Machine Operator Helper

- Assisted in developing and implementing quality control procedures to meet industry standards.

- Collaborated with other team members to ensure smooth machine operation and maintain production schedules.

- Operated CNC beveling machines, programming the machine to execute complex cuts and shapes.

- Diagnosed and resolved machine malfunctions, ensuring minimal downtime and maintaining machine efficiency.

Beveling and Edging Machine Operator Helper

- Assisted in the operation of beveling and edging machines, ensuring precise cuts and smooth finishes on a variety of materials.

- Monitored machine performance and adjusted settings to optimize productivity and ensure product quality.

- Loaded and unloaded materials into and from the machines, ensuring efficient material handling.

- Cleaned and maintained machines and work area, adhering to safety protocols.

Accomplishments

- Assisted in optimizing beveling and edging processes, resulting in a 15% increase in production efficiency.

- Developed and implemented a new method for adjusting machine parameters, reducing setup time by 20%.

- Trained and mentored junior operators, improving their proficiency and reducing training costs.

- Identified and resolved technical issues related to beveling and edging machines, minimizing downtime.

- Collaborated with engineers to design and implement modifications to improve machine performance.

Certificates

- Certified Beveling and Edging Machine Operator

- Certified Quality Inspector

- Certified Six Sigma Green Belt

- Certified Lean Six Sigma Black Belt

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Beveling and Edging Machine Operator Helper

- Highlight your technical skills and experience in operating and maintaining beveling and edging machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency.

- Showcase your problem-solving abilities and innovative approaches to improving machine performance and reducing downtime.

- Emphasize your commitment to safety and quality control, as these are crucial aspects of the role.

- Consider including any relevant certifications or training programs that enhance your qualifications.

Essential Experience Highlights for a Strong Beveling and Edging Machine Operator Helper Resume

- Assisted in the operation, setup, and maintenance of beveling and edging machines to ensure optimal performance.

- Monitored and inspected materials to ensure they meet quality standards, and identified and resolved any defects promptly.

- Participated in the development and implementation of new processes and procedures to improve production efficiency.

- Collaborated with engineers and technicians to diagnose and resolve technical issues related to beveling and edging machines, minimizing downtime.

- Trained and mentored junior operators, providing guidance and support to improve their proficiency and reduce training costs.

- Assisted in the maintenance of a clean and organized work environment, adhering to safety regulations and protocols.

- Communicated effectively with supervisors, engineers, and other team members to ensure smooth coordination and problem-solving.

Frequently Asked Questions (FAQ’s) For Beveling and Edging Machine Operator Helper

What are the primary responsibilities of a Beveling and Edging Machine Operator Helper?

Beveling and Edging Machine Operator Helpers assist in the operation, setup, and maintenance of beveling and edging machines. They also monitor materials to ensure quality standards, troubleshoot and resolve technical issues, and train junior operators.

What skills are required to be successful in this role?

Successful Beveling and Edging Machine Operator Helpers possess technical skills in operating and maintaining beveling and edging machines, as well as strong problem-solving abilities. They are also proficient in quality control, safety procedures, and communication.

What are the career prospects for Beveling and Edging Machine Operator Helpers?

With experience and additional training, Beveling and Edging Machine Operator Helpers can advance to positions such as Beveling and Edging Machine Operators, Supervisors, or Quality Control Inspectors.

How can I prepare for a career as a Beveling and Edging Machine Operator Helper?

To prepare for this role, consider pursuing an Associate Degree in Manufacturing Technology or a related field. Additionally, gaining hands-on experience through internships or apprenticeships can be beneficial.

What is the work environment like for Beveling and Edging Machine Operator Helpers?

Beveling and Edging Machine Operator Helpers typically work in manufacturing facilities, operating and maintaining machinery in a fast-paced and demanding environment. They must adhere to strict safety protocols and wear appropriate personal protective equipment.

Are there any certifications or training programs available for Beveling and Edging Machine Operator Helpers?

Yes, there are several certifications and training programs available, such as the Certified Beveling and Edging Machine Operator (CBEMO) certification offered by the National Association of Manufacturers (NAM).