Are you a seasoned Beveling Machine Operator seeking a new career path? Discover our professionally built Beveling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

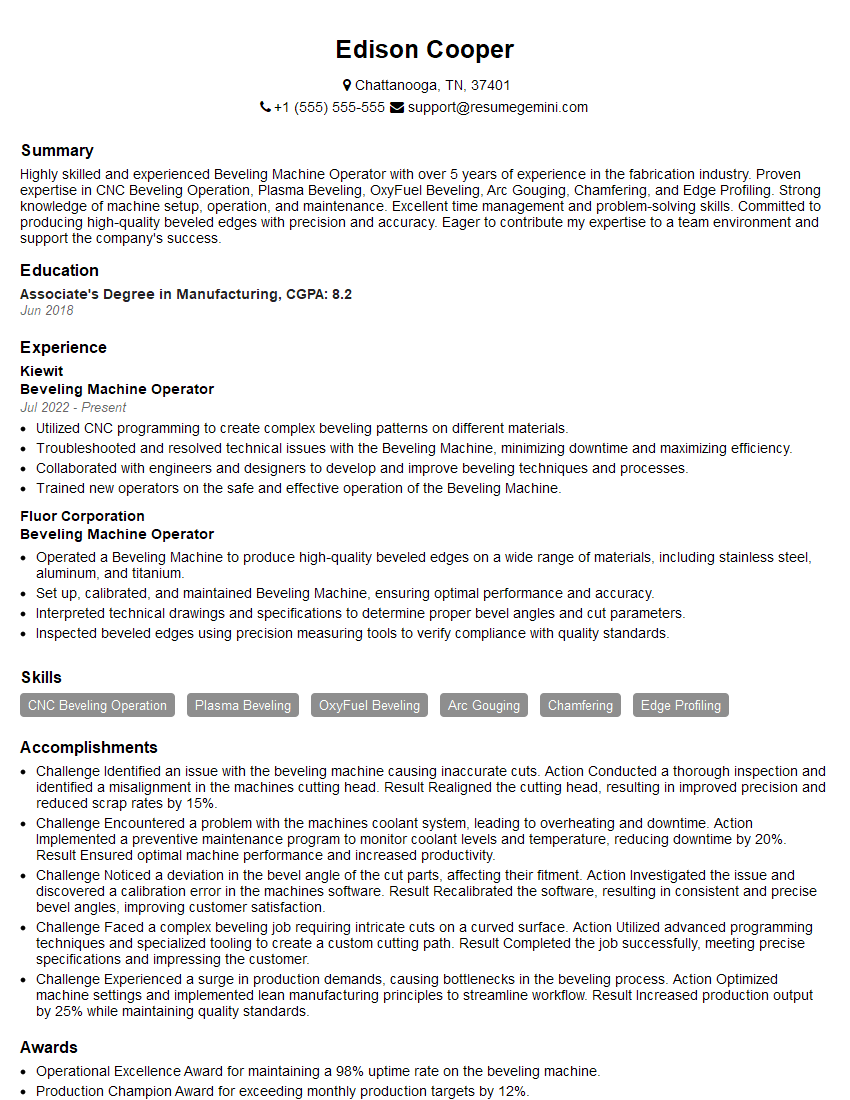

Edison Cooper

Beveling Machine Operator

Summary

Highly skilled and experienced Beveling Machine Operator with over 5 years of experience in the fabrication industry. Proven expertise in CNC Beveling Operation, Plasma Beveling, OxyFuel Beveling, Arc Gouging, Chamfering, and Edge Profiling. Strong knowledge of machine setup, operation, and maintenance. Excellent time management and problem-solving skills. Committed to producing high-quality beveled edges with precision and accuracy. Eager to contribute my expertise to a team environment and support the company’s success.

Education

Associate’s Degree in Manufacturing

June 2018

Skills

- CNC Beveling Operation

- Plasma Beveling

- OxyFuel Beveling

- Arc Gouging

- Chamfering

- Edge Profiling

Work Experience

Beveling Machine Operator

- Utilized CNC programming to create complex beveling patterns on different materials.

- Troubleshooted and resolved technical issues with the Beveling Machine, minimizing downtime and maximizing efficiency.

- Collaborated with engineers and designers to develop and improve beveling techniques and processes.

- Trained new operators on the safe and effective operation of the Beveling Machine.

Beveling Machine Operator

- Operated a Beveling Machine to produce high-quality beveled edges on a wide range of materials, including stainless steel, aluminum, and titanium.

- Set up, calibrated, and maintained Beveling Machine, ensuring optimal performance and accuracy.

- Interpreted technical drawings and specifications to determine proper bevel angles and cut parameters.

- Inspected beveled edges using precision measuring tools to verify compliance with quality standards.

Accomplishments

- Challenge Identified an issue with the beveling machine causing inaccurate cuts. Action Conducted a thorough inspection and identified a misalignment in the machines cutting head. Result Realigned the cutting head, resulting in improved precision and reduced scrap rates by 15%.

- Challenge Encountered a problem with the machines coolant system, leading to overheating and downtime. Action Implemented a preventive maintenance program to monitor coolant levels and temperature, reducing downtime by 20%. Result Ensured optimal machine performance and increased productivity.

- Challenge Noticed a deviation in the bevel angle of the cut parts, affecting their fitment. Action Investigated the issue and discovered a calibration error in the machines software. Result Recalibrated the software, resulting in consistent and precise bevel angles, improving customer satisfaction.

- Challenge Faced a complex beveling job requiring intricate cuts on a curved surface. Action Utilized advanced programming techniques and specialized tooling to create a custom cutting path. Result Completed the job successfully, meeting precise specifications and impressing the customer.

- Challenge Experienced a surge in production demands, causing bottlenecks in the beveling process. Action Optimized machine settings and implemented lean manufacturing principles to streamline workflow. Result Increased production output by 25% while maintaining quality standards.

Awards

- Operational Excellence Award for maintaining a 98% uptime rate on the beveling machine.

- Production Champion Award for exceeding monthly production targets by 12%.

- Safety Excellence Award for maintaining an unblemished safety record for over 5 years.

- Outstanding Performance Award for consistently delivering highquality parts with nearzero defects.

Certificates

- AWS Certified Welder

- ASME Certified Boilermaker

- ISO 9001 Certification

- OSHA 30Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Beveling Machine Operator

- Highlight your experience with specific beveling techniques, such as CNC, plasma, or oxyfuel, to demonstrate your versatility.

- Showcase your knowledge of machine setup and operation, emphasizing your ability to achieve precise and accurate bevels.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work.

- Tailor your resume to the specific job you’re applying for, highlighting the skills and experience that are most relevant to that role.

Essential Experience Highlights for a Strong Beveling Machine Operator Resume

- Operate and maintain CNC Beveling Machines to prepare metal edges for welding and fabrication.

- Set up and adjust machines according to specifications, ensuring optimal performance and precision.

- Select and install appropriate cutting tips and consumables for different materials and thicknesses.

- Monitor and control cutting parameters such as speed, feed rate, and gas flow to achieve desired bevel profiles.

- Inspect and measure beveled edges to ensure they meet quality standards and customer requirements.

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain production efficiency.

- Maintain a clean and organized work area, adhering to safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Beveling Machine Operator

What are the key skills required for a Beveling Machine Operator?

Key skills for a Beveling Machine Operator include CNC Beveling Operation, Plasma Beveling, OxyFuel Beveling, Arc Gouging, Chamfering, Edge Profiling, and a strong understanding of machine setup and operation.

What industries employ Beveling Machine Operators?

Beveling Machine Operators are employed in various industries such as shipbuilding, construction, automotive, and manufacturing.

What is the average salary for a Beveling Machine Operator?

According to Indeed, the average salary for a Beveling Machine Operator in the United States is around $45,000 per year.

What are the career prospects for a Beveling Machine Operator?

With experience and additional training, Beveling Machine Operators can advance to positions such as Supervisor, Quality Control Inspector, or Production Manager.

What are some tips for writing a standout Beveling Machine Operator resume?

Highlight your relevant skills and experience, quantify your accomplishments, tailor your resume to the specific job you’re applying for, and proofread carefully before submitting.

What are the safety precautions to be taken while operating a Beveling Machine?

Always wear appropriate safety gear, ensure the machine is properly grounded and maintained, follow operating instructions carefully, and be aware of potential hazards such as sparks and sharp edges.