Are you a seasoned Beveller Operator seeking a new career path? Discover our professionally built Beveller Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

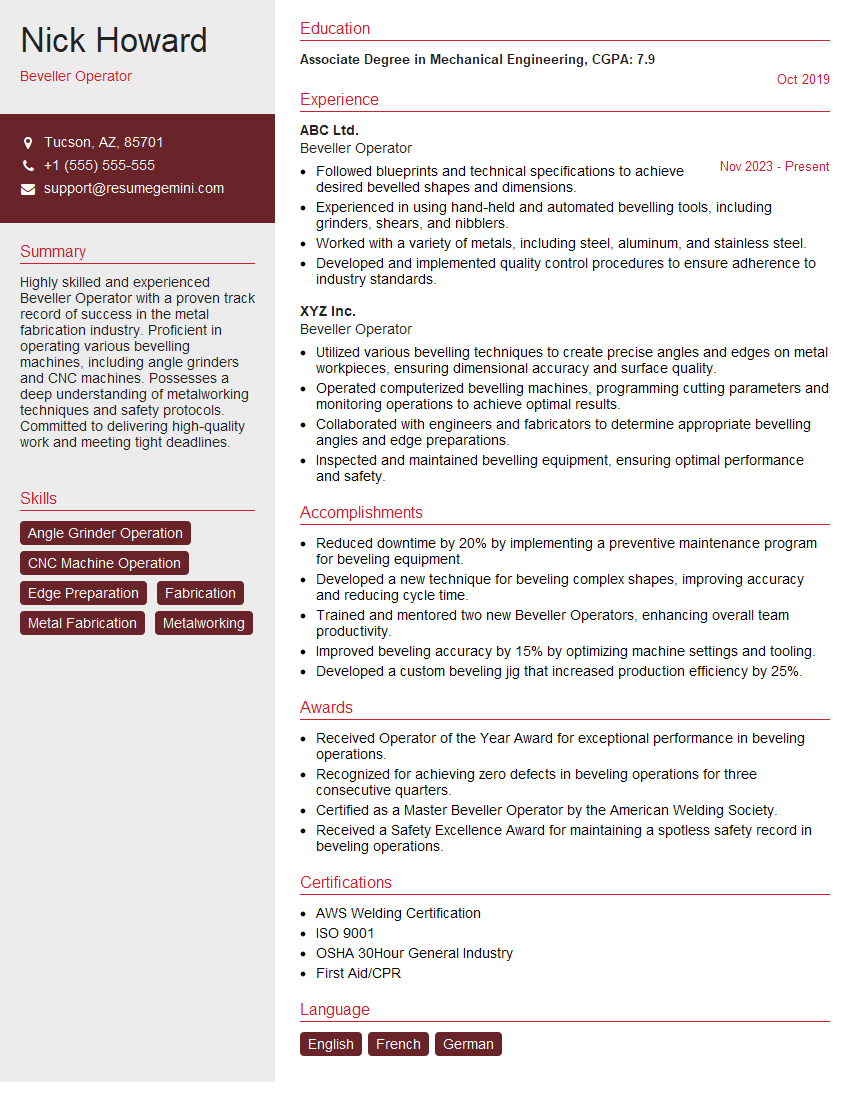

Nick Howard

Beveller Operator

Summary

Highly skilled and experienced Beveller Operator with a proven track record of success in the metal fabrication industry. Proficient in operating various bevelling machines, including angle grinders and CNC machines. Possesses a deep understanding of metalworking techniques and safety protocols. Committed to delivering high-quality work and meeting tight deadlines.

Education

Associate Degree in Mechanical Engineering

October 2019

Skills

- Angle Grinder Operation

- CNC Machine Operation

- Edge Preparation

- Fabrication

- Metal Fabrication

- Metalworking

Work Experience

Beveller Operator

- Followed blueprints and technical specifications to achieve desired bevelled shapes and dimensions.

- Experienced in using hand-held and automated bevelling tools, including grinders, shears, and nibblers.

- Worked with a variety of metals, including steel, aluminum, and stainless steel.

- Developed and implemented quality control procedures to ensure adherence to industry standards.

Beveller Operator

- Utilized various bevelling techniques to create precise angles and edges on metal workpieces, ensuring dimensional accuracy and surface quality.

- Operated computerized bevelling machines, programming cutting parameters and monitoring operations to achieve optimal results.

- Collaborated with engineers and fabricators to determine appropriate bevelling angles and edge preparations.

- Inspected and maintained bevelling equipment, ensuring optimal performance and safety.

Accomplishments

- Reduced downtime by 20% by implementing a preventive maintenance program for beveling equipment.

- Developed a new technique for beveling complex shapes, improving accuracy and reducing cycle time.

- Trained and mentored two new Beveller Operators, enhancing overall team productivity.

- Improved beveling accuracy by 15% by optimizing machine settings and tooling.

- Developed a custom beveling jig that increased production efficiency by 25%.

Awards

- Received Operator of the Year Award for exceptional performance in beveling operations.

- Recognized for achieving zero defects in beveling operations for three consecutive quarters.

- Certified as a Master Beveller Operator by the American Welding Society.

- Received a Safety Excellence Award for maintaining a spotless safety record in beveling operations.

Certificates

- AWS Welding Certification

- ISO 9001

- OSHA 30Hour General Industry

- First Aid/CPR

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Beveller Operator

- Highlight your experience and skills in operating bevelling machines, particularly angle grinders and CNC machines.

- Showcase your knowledge of metalworking techniques, including edge preparation, fabrication, and metalworking.

- Emphasize your ability to work independently and as part of a team, and your commitment to safety.

- Include quantifiable results and specific examples to demonstrate your impact on previous projects.

Essential Experience Highlights for a Strong Beveller Operator Resume

- Operate and maintain bevelling machines, including angle grinders and CNC machines

- Prepare metal edges for welding, cutting, and other fabrication processes

- Ensure precise and consistent bevelling angles to meet specifications

- Monitor and adjust machine settings to optimize performance and prevent defects

- Inspect finished bevelled edges to ensure quality and accuracy

- Follow safety protocols and maintain a clean and organized work area

- Collaborate with other team members to complete projects efficiently

Frequently Asked Questions (FAQ’s) For Beveller Operator

What is the role of a Beveller Operator?

A Beveller Operator is responsible for preparing metal edges for welding, cutting, and other fabrication processes. They operate and maintain bevelling machines, including angle grinders and CNC machines, to create precise and consistent bevelling angles.

What skills are required to be a Beveller Operator?

Key skills for a Beveller Operator include angle grinder operation, CNC machine operation, edge preparation, fabrication, metal fabrication, and metalworking.

What is the typical work environment for a Beveller Operator?

Beveller Operators typically work in fabrication shops or industrial settings. They may work with various metals, such as steel, aluminum, and stainless steel.

What are the career prospects for a Beveller Operator?

Beveller Operators can advance their careers by becoming supervisors or managers in the metal fabrication industry. They may also specialize in a particular type of bevelling or metalworking.

What is the salary range for a Beveller Operator?

The salary range for a Beveller Operator can vary depending on experience, location, and employer. According to Indeed, the average salary for a Beveller Operator in the United States is around $25,000 per year.

What are the safety considerations for a Beveller Operator?

Beveller Operators must follow safety protocols to prevent accidents and injuries. This includes wearing appropriate safety gear, such as gloves, eye protection, and hearing protection, and operating machines according to manufacturer guidelines.