Are you a seasoned Blast Furnace Operator seeking a new career path? Discover our professionally built Blast Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

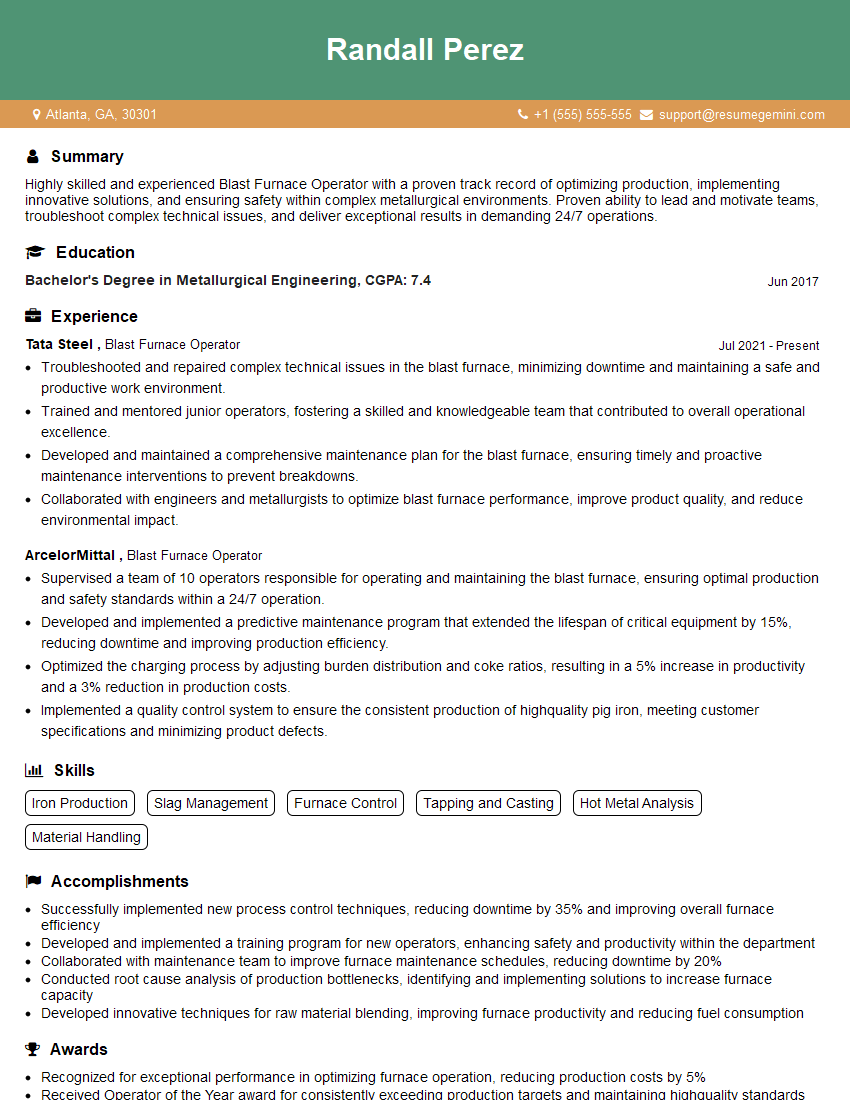

Randall Perez

Blast Furnace Operator

Summary

Highly skilled and experienced Blast Furnace Operator with a proven track record of optimizing production, implementing innovative solutions, and ensuring safety within complex metallurgical environments. Proven ability to lead and motivate teams, troubleshoot complex technical issues, and deliver exceptional results in demanding 24/7 operations.

Education

Bachelor’s Degree in Metallurgical Engineering

June 2017

Skills

- Iron Production

- Slag Management

- Furnace Control

- Tapping and Casting

- Hot Metal Analysis

- Material Handling

Work Experience

Blast Furnace Operator

- Troubleshooted and repaired complex technical issues in the blast furnace, minimizing downtime and maintaining a safe and productive work environment.

- Trained and mentored junior operators, fostering a skilled and knowledgeable team that contributed to overall operational excellence.

- Developed and maintained a comprehensive maintenance plan for the blast furnace, ensuring timely and proactive maintenance interventions to prevent breakdowns.

- Collaborated with engineers and metallurgists to optimize blast furnace performance, improve product quality, and reduce environmental impact.

Blast Furnace Operator

- Supervised a team of 10 operators responsible for operating and maintaining the blast furnace, ensuring optimal production and safety standards within a 24/7 operation.

- Developed and implemented a predictive maintenance program that extended the lifespan of critical equipment by 15%, reducing downtime and improving production efficiency.

- Optimized the charging process by adjusting burden distribution and coke ratios, resulting in a 5% increase in productivity and a 3% reduction in production costs.

- Implemented a quality control system to ensure the consistent production of highquality pig iron, meeting customer specifications and minimizing product defects.

Accomplishments

- Successfully implemented new process control techniques, reducing downtime by 35% and improving overall furnace efficiency

- Developed and implemented a training program for new operators, enhancing safety and productivity within the department

- Collaborated with maintenance team to improve furnace maintenance schedules, reducing downtime by 20%

- Conducted root cause analysis of production bottlenecks, identifying and implementing solutions to increase furnace capacity

- Developed innovative techniques for raw material blending, improving furnace productivity and reducing fuel consumption

Awards

- Recognized for exceptional performance in optimizing furnace operation, reducing production costs by 5%

- Received Operator of the Year award for consistently exceeding production targets and maintaining highquality standards

- Recognized by management for exceptional troubleshooting skills, identifying and resolving critical furnace issues quickly and effectively

- Received Excellence in Safety award for consistently adhering to safety protocols and promoting a safe work environment

Certificates

- Blast Furnace Operator Certification (BOC)

- National Center for Construction Education and Research (NCCER)

- American Welding Society (AWS)

- OSHA Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blast Furnace Operator

- Highlight your technical expertise and experience in iron production, slag management, and furnace control.

- Quantify your accomplishments with specific metrics and outcomes to demonstrate your impact.

- Showcase your leadership and management abilities by emphasizing your role in supervising teams and implementing safety initiatives.

- Emphasize your commitment to continuous improvement and innovation by highlighting your involvement in predictive maintenance programs and process optimization projects.

Essential Experience Highlights for a Strong Blast Furnace Operator Resume

- Supervise a team of operators and ensure optimal production and safety standards.

- Develop and implement predictive maintenance programs to extend equipment lifespan and minimize downtime.

- Optimize the charging process to increase productivity and reduce production costs.

- Implement quality control systems to ensure consistent production of high-quality pig iron.

- Troubleshoot and repair complex technical issues in the blast furnace, minimizing downtime and maintaining a safe work environment.

- Train and mentor junior operators to foster a skilled and knowledgeable team.

- Collaborate with engineers and metallurgists to optimize blast furnace performance and reduce environmental impact.

Frequently Asked Questions (FAQ’s) For Blast Furnace Operator

What are the key skills required for a Blast Furnace Operator?

Key skills include iron production, slag management, furnace control, tapping and casting, hot metal analysis, and material handling.

What are the career prospects for a Blast Furnace Operator?

Experienced Blast Furnace Operators can advance to roles such as Supervisor, Production Manager, or Plant Manager in the metallurgical industry.

What is the work environment like for a Blast Furnace Operator?

Blast Furnace Operators typically work in a hot, noisy, and potentially hazardous environment and may be required to work shifts or overtime.

What are the safety precautions that Blast Furnace Operators must follow?

Blast Furnace Operators must adhere to strict safety regulations, including wearing protective clothing, using proper equipment, and following established safety procedures.

What are the physical demands of being a Blast Furnace Operator?

Blast Furnace Operators may be required to perform physically demanding tasks such as lifting heavy objects, working in confined spaces, and climbing ladders or stairs.

How can I prepare for a career as a Blast Furnace Operator?

To prepare for a career as a Blast Furnace Operator, consider pursuing a degree in metallurgical engineering or a related field and gaining experience in metal production or manufacturing.