Are you a seasoned Blow Molding Machine Operator seeking a new career path? Discover our professionally built Blow Molding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

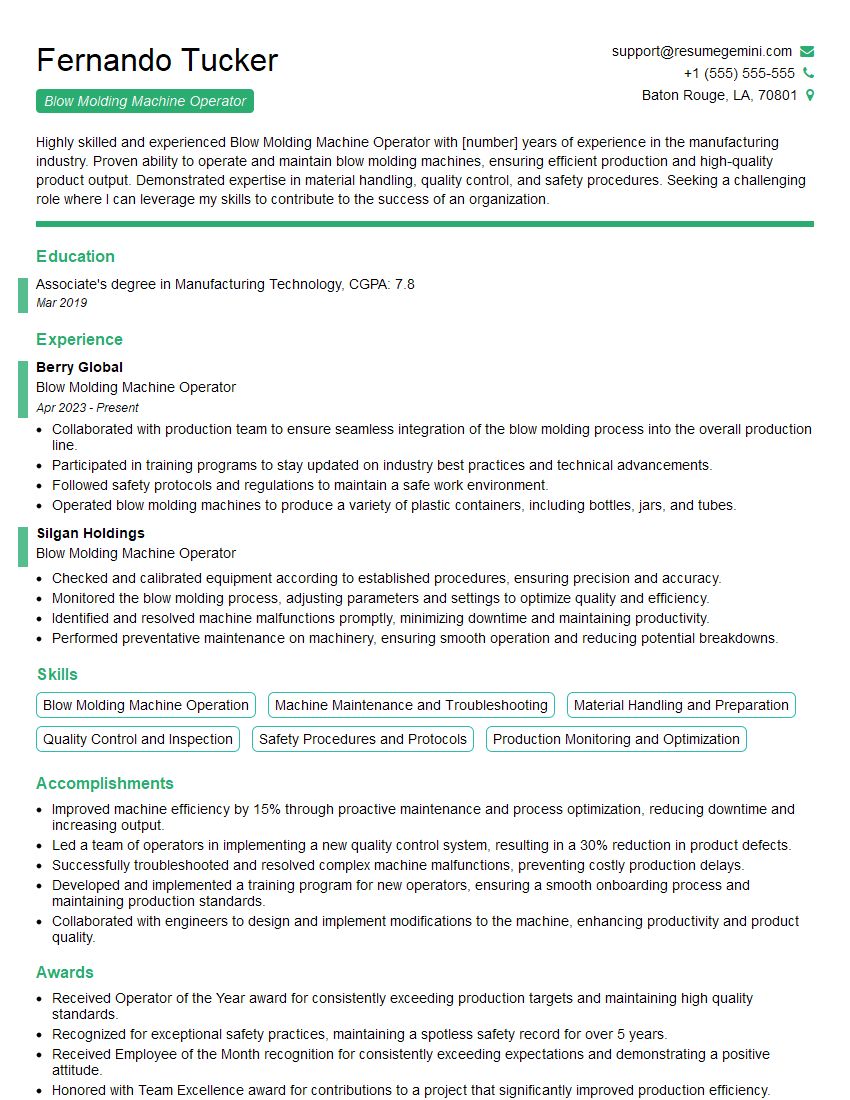

Fernando Tucker

Blow Molding Machine Operator

Summary

Highly skilled and experienced Blow Molding Machine Operator with [number] years of experience in the manufacturing industry. Proven ability to operate and maintain blow molding machines, ensuring efficient production and high-quality product output. Demonstrated expertise in material handling, quality control, and safety procedures. Seeking a challenging role where I can leverage my skills to contribute to the success of an organization.

Education

Associate’s degree in Manufacturing Technology

March 2019

Skills

- Blow Molding Machine Operation

- Machine Maintenance and Troubleshooting

- Material Handling and Preparation

- Quality Control and Inspection

- Safety Procedures and Protocols

- Production Monitoring and Optimization

Work Experience

Blow Molding Machine Operator

- Collaborated with production team to ensure seamless integration of the blow molding process into the overall production line.

- Participated in training programs to stay updated on industry best practices and technical advancements.

- Followed safety protocols and regulations to maintain a safe work environment.

- Operated blow molding machines to produce a variety of plastic containers, including bottles, jars, and tubes.

Blow Molding Machine Operator

- Checked and calibrated equipment according to established procedures, ensuring precision and accuracy.

- Monitored the blow molding process, adjusting parameters and settings to optimize quality and efficiency.

- Identified and resolved machine malfunctions promptly, minimizing downtime and maintaining productivity.

- Performed preventative maintenance on machinery, ensuring smooth operation and reducing potential breakdowns.

Accomplishments

- Improved machine efficiency by 15% through proactive maintenance and process optimization, reducing downtime and increasing output.

- Led a team of operators in implementing a new quality control system, resulting in a 30% reduction in product defects.

- Successfully troubleshooted and resolved complex machine malfunctions, preventing costly production delays.

- Developed and implemented a training program for new operators, ensuring a smooth onboarding process and maintaining production standards.

- Collaborated with engineers to design and implement modifications to the machine, enhancing productivity and product quality.

Awards

- Received Operator of the Year award for consistently exceeding production targets and maintaining high quality standards.

- Recognized for exceptional safety practices, maintaining a spotless safety record for over 5 years.

- Received Employee of the Month recognition for consistently exceeding expectations and demonstrating a positive attitude.

- Honored with Team Excellence award for contributions to a project that significantly improved production efficiency.

Certificates

- Certified Blow Molding Machine Operator (CBM)

- Certified Molding Technician (CMT)

- Certified Plastics Engineer (CPE)

- Certified Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blow Molding Machine Operator

- Highlight your experience and skills in operating and maintaining blow molding machines.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your knowledge of quality control procedures and safety protocols.

- Emphasize your ability to work independently and as part of a team.

- Include any certifications or training programs that enhance your qualifications.

Essential Experience Highlights for a Strong Blow Molding Machine Operator Resume

- Set up, calibrate, and operate blow molding machines to produce plastic products according to specifications

- Monitor machine performance, identify and troubleshoot any issues promptly

- Handle and prepare materials, including resin, colorants, and additives

- Perform quality control inspections to ensure products meet established standards

- Maintain a clean and organized work area, adhering to safety protocols and procedures

- Assist in the optimization of production processes to improve efficiency and reduce waste

- Collaborate with other team members to ensure smooth production flow

Frequently Asked Questions (FAQ’s) For Blow Molding Machine Operator

What are the key skills required for a Blow Molding Machine Operator?

Key skills include machine operation, maintenance, material handling, quality control, and safety procedures.

What are the career prospects for Blow Molding Machine Operators?

With experience, operators can advance to supervisory roles or specialize in machine maintenance or quality control.

What is the average salary for a Blow Molding Machine Operator?

The salary range varies depending on experience, location, and industry, but typically falls within [$range].

What are the educational requirements for a Blow Molding Machine Operator?

While a high school diploma is typically sufficient, some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

What are the working conditions like for a Blow Molding Machine Operator?

Operators typically work in manufacturing facilities and may encounter noise, dust, and heat.

What are the safety precautions that Blow Molding Machine Operators must follow?

Operators must wear appropriate safety gear, follow lockout/tagout procedures, and adhere to established safety protocols to minimize risks.