Are you a seasoned Bobbin Fixer seeking a new career path? Discover our professionally built Bobbin Fixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

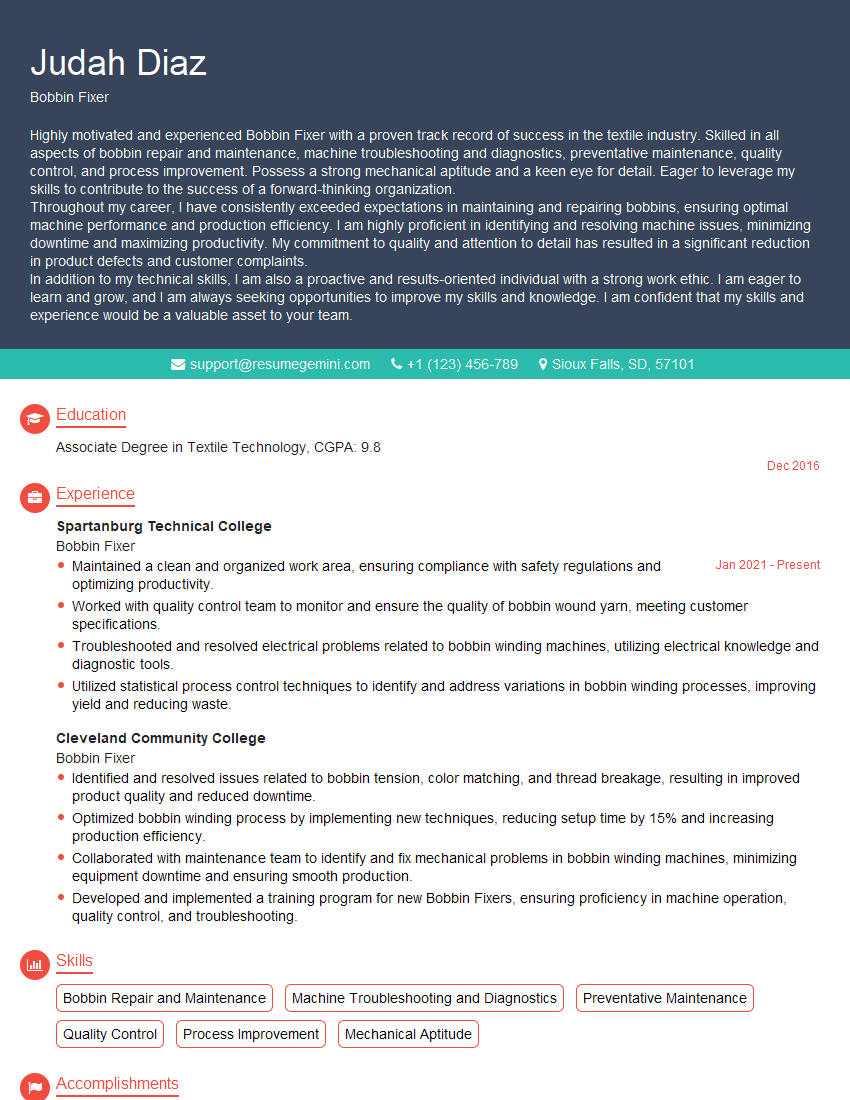

Judah Diaz

Bobbin Fixer

Summary

Highly motivated and experienced Bobbin Fixer with a proven track record of success in the textile industry. Skilled in all aspects of bobbin repair and maintenance, machine troubleshooting and diagnostics, preventative maintenance, quality control, and process improvement. Possess a strong mechanical aptitude and a keen eye for detail. Eager to leverage my skills to contribute to the success of a forward-thinking organization.

Throughout my career, I have consistently exceeded expectations in maintaining and repairing bobbins, ensuring optimal machine performance and production efficiency. I am highly proficient in identifying and resolving machine issues, minimizing downtime and maximizing productivity. My commitment to quality and attention to detail has resulted in a significant reduction in product defects and customer complaints.

In addition to my technical skills, I am also a proactive and results-oriented individual with a strong work ethic. I am eager to learn and grow, and I am always seeking opportunities to improve my skills and knowledge. I am confident that my skills and experience would be a valuable asset to your team.

Education

Associate Degree in Textile Technology

December 2016

Skills

- Bobbin Repair and Maintenance

- Machine Troubleshooting and Diagnostics

- Preventative Maintenance

- Quality Control

- Process Improvement

- Mechanical Aptitude

Work Experience

Bobbin Fixer

- Maintained a clean and organized work area, ensuring compliance with safety regulations and optimizing productivity.

- Worked with quality control team to monitor and ensure the quality of bobbin wound yarn, meeting customer specifications.

- Troubleshooted and resolved electrical problems related to bobbin winding machines, utilizing electrical knowledge and diagnostic tools.

- Utilized statistical process control techniques to identify and address variations in bobbin winding processes, improving yield and reducing waste.

Bobbin Fixer

- Identified and resolved issues related to bobbin tension, color matching, and thread breakage, resulting in improved product quality and reduced downtime.

- Optimized bobbin winding process by implementing new techniques, reducing setup time by 15% and increasing production efficiency.

- Collaborated with maintenance team to identify and fix mechanical problems in bobbin winding machines, minimizing equipment downtime and ensuring smooth production.

- Developed and implemented a training program for new Bobbin Fixers, ensuring proficiency in machine operation, quality control, and troubleshooting.

Accomplishments

- Installed and calibrated bobbin winding machines, ensuring optimal thread tension and winding quality.

- Repaired and maintained bobbin holders, preventing thread breaks and reducing downtime.

- Developed and implemented a preventive maintenance schedule, extending the lifespan of bobbin winding equipment.

- Troubleshooted and resolved critical bobbin winding issues, minimizing production delays.

- Trained and supervised new bobbin fixers, ensuring consistent quality and efficiency.

Certificates

- Certified Bobbin Fixer Technician

- Machine Maintenance Technician Level I

- ISO 9001:2015 Quality Management

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bobbin Fixer

Highlight your technical skills.

Be sure to list all of the relevant skills you have in bobbin repair and maintenance, machine troubleshooting and diagnostics, preventative maintenance, quality control, and process improvement.Showcase your experience.

Quantify your accomplishments whenever possible. For example, instead of saying “I repaired bobbins,” say “I repaired over 1,000 bobbins per month, resulting in a 10% increase in production efficiency.”Tailor your resume to the job you’re applying for.

Take the time to read the job description carefully and highlight the skills and experience that are most relevant to the position.Proofread your resume carefully.

Make sure there are no errors in grammar or spelling. A well-written resume will make you stand out from other candidates.Use keywords.

Include relevant keywords throughout your resume, especially in your skills section and summary. This will help your resume get noticed by potential employers.

Essential Experience Highlights for a Strong Bobbin Fixer Resume

- Repair and maintain bobbins, ensuring they meet quality standards

- Troubleshoot and diagnose machine issues, identifying root causes and implementing solutions

- Perform preventative maintenance on machines to minimize downtime and extend equipment life

- Conduct quality control inspections to ensure products meet specifications

- Identify and implement process improvements to enhance efficiency and reduce waste

- Train and mentor new bobbin fixers to ensure a seamless transition

Frequently Asked Questions (FAQ’s) For Bobbin Fixer

What is a Bobbin Fixer?

A Bobbin Fixer is a skilled technician responsible for repairing and maintaining bobbins used in textile machinery. They ensure that bobbins meet quality standards, troubleshoot and diagnose machine issues, perform preventative maintenance, conduct quality control inspections, and identify and implement process improvements.

What are the key skills required for a Bobbin Fixer?

The key skills required for a Bobbin Fixer include bobbin repair and maintenance, machine troubleshooting and diagnostics, preventative maintenance, quality control, process improvement, and mechanical aptitude.

What qualifications are required to become a Bobbin Fixer?

A high school diploma or equivalent is typically required to become a Bobbin Fixer. Some employers may prefer candidates with an Associate Degree in Textile Technology or a related field.

What is the work environment of a Bobbin Fixer like?

Bobbin Fixers typically work in a manufacturing environment, such as a textile mill or a factory. They may work independently or as part of a team, and they may be required to work overtime or on weekends to meet production deadlines.

What is the career outlook for Bobbin Fixers?

The career outlook for Bobbin Fixers is expected to be good over the next few years. The textile industry is growing, and there is a increasing demand for skilled technicians to maintain and repair textile machinery.

What are the earning prospects for Bobbin Fixers?

The earning prospects for Bobbin Fixers vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Textile Machine Operators and Tenders was $35,650 in May 2021.