Are you a seasoned Boiler Shop Mechanic seeking a new career path? Discover our professionally built Boiler Shop Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

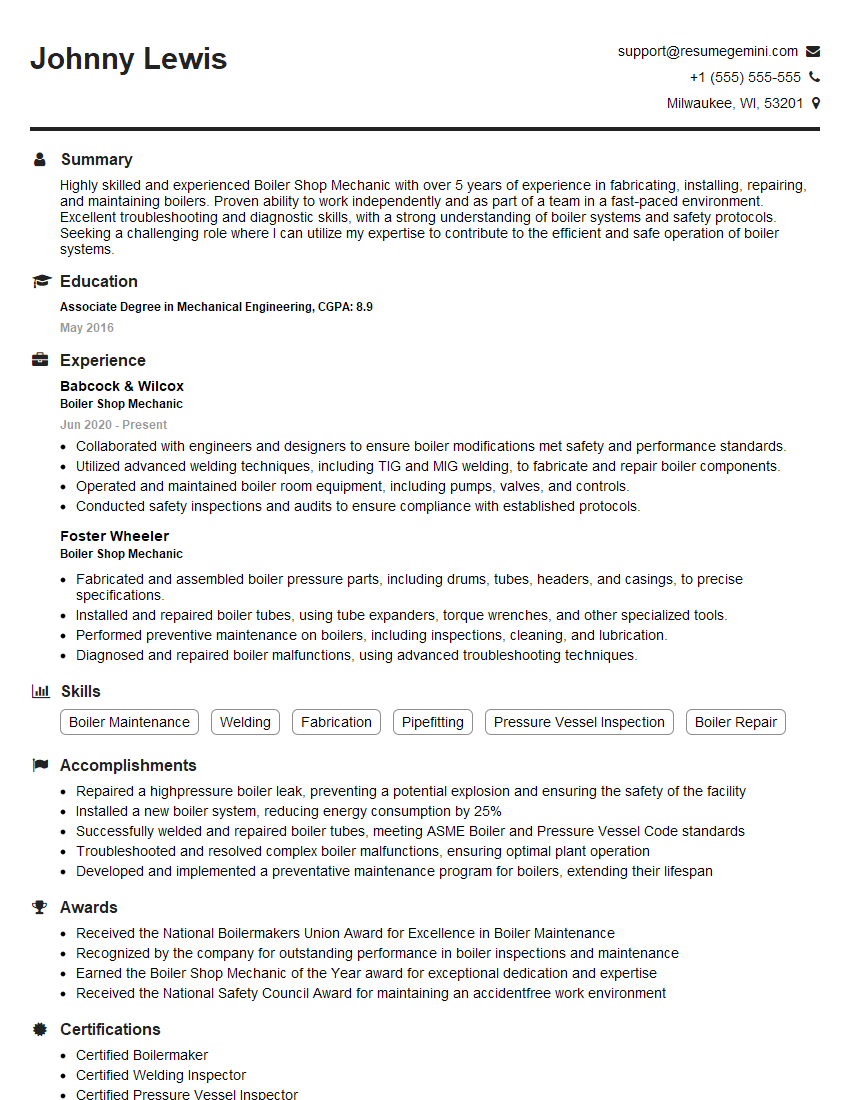

Johnny Lewis

Boiler Shop Mechanic

Summary

Highly skilled and experienced Boiler Shop Mechanic with over 5 years of experience in fabricating, installing, repairing, and maintaining boilers. Proven ability to work independently and as part of a team in a fast-paced environment. Excellent troubleshooting and diagnostic skills, with a strong understanding of boiler systems and safety protocols. Seeking a challenging role where I can utilize my expertise to contribute to the efficient and safe operation of boiler systems.

Education

Associate Degree in Mechanical Engineering

May 2016

Skills

- Boiler Maintenance

- Welding

- Fabrication

- Pipefitting

- Pressure Vessel Inspection

- Boiler Repair

Work Experience

Boiler Shop Mechanic

- Collaborated with engineers and designers to ensure boiler modifications met safety and performance standards.

- Utilized advanced welding techniques, including TIG and MIG welding, to fabricate and repair boiler components.

- Operated and maintained boiler room equipment, including pumps, valves, and controls.

- Conducted safety inspections and audits to ensure compliance with established protocols.

Boiler Shop Mechanic

- Fabricated and assembled boiler pressure parts, including drums, tubes, headers, and casings, to precise specifications.

- Installed and repaired boiler tubes, using tube expanders, torque wrenches, and other specialized tools.

- Performed preventive maintenance on boilers, including inspections, cleaning, and lubrication.

- Diagnosed and repaired boiler malfunctions, using advanced troubleshooting techniques.

Accomplishments

- Repaired a highpressure boiler leak, preventing a potential explosion and ensuring the safety of the facility

- Installed a new boiler system, reducing energy consumption by 25%

- Successfully welded and repaired boiler tubes, meeting ASME Boiler and Pressure Vessel Code standards

- Troubleshooted and resolved complex boiler malfunctions, ensuring optimal plant operation

- Developed and implemented a preventative maintenance program for boilers, extending their lifespan

Awards

- Received the National Boilermakers Union Award for Excellence in Boiler Maintenance

- Recognized by the company for outstanding performance in boiler inspections and maintenance

- Earned the Boiler Shop Mechanic of the Year award for exceptional dedication and expertise

- Received the National Safety Council Award for maintaining an accidentfree work environment

Certificates

- Certified Boilermaker

- Certified Welding Inspector

- Certified Pressure Vessel Inspector

- Certified Boiler Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Boiler Shop Mechanic

- Highlight your experience and skills in boiler fabrication, installation, and repair.

- Showcase your knowledge of boiler systems and safety protocols.

- Emphasize your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

Essential Experience Highlights for a Strong Boiler Shop Mechanic Resume

- Fabricated and assembled boiler pressure parts, including drums, tubes, headers, and casings, to precise specifications.

- Installed and repaired boiler tubes, using tube expanders, torque wrenches, and other specialized tools.

- Performed preventive maintenance on boilers, including inspections, cleaning, and lubrication.

- Diagnosed and repaired boiler malfunctions, using advanced troubleshooting techniques.

- Collaborated with engineers and designers to ensure boiler modifications met safety and performance standards.

- Utilized advanced welding techniques, including TIG and MIG welding, to fabricate and repair boiler components.

- Operated and maintained boiler room equipment, including pumps, valves, and controls.

Frequently Asked Questions (FAQ’s) For Boiler Shop Mechanic

What are the primary responsibilities of a Boiler Shop Mechanic?

Boiler Shop Mechanics are responsible for fabricating, installing, repairing, and maintaining boilers. Their duties include welding, pipefitting, pressure vessel inspection, and boiler repair.

What are the essential skills required to be a successful Boiler Shop Mechanic?

Boiler Shop Mechanics must have strong welding, fabrication, and pipefitting skills. They also need to be knowledgeable about boiler systems, safety protocols, and troubleshooting techniques.

What are the career prospects for Boiler Shop Mechanics?

Boiler Shop Mechanics can advance to supervisory or management positions within the industry. They can also specialize in specific areas of boiler maintenance and repair.

What are the educational requirements to become a Boiler Shop Mechanic?

An Associate Degree in Mechanical Engineering or a related field is typically required to become a Boiler Shop Mechanic.

What are the typical working conditions for Boiler Shop Mechanics?

Boiler Shop Mechanics typically work in industrial settings, such as power plants and manufacturing facilities. They may work in confined spaces and be exposed to noise, heat, and hazardous materials.

What are the safety precautions that Boiler Shop Mechanics must follow?

Boiler Shop Mechanics must adhere to strict safety protocols to prevent accidents and injuries. These protocols include wearing appropriate protective gear, following lockout/tagout procedures, and being aware of potential hazards.