Are you a seasoned Bolting Machine Operator seeking a new career path? Discover our professionally built Bolting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

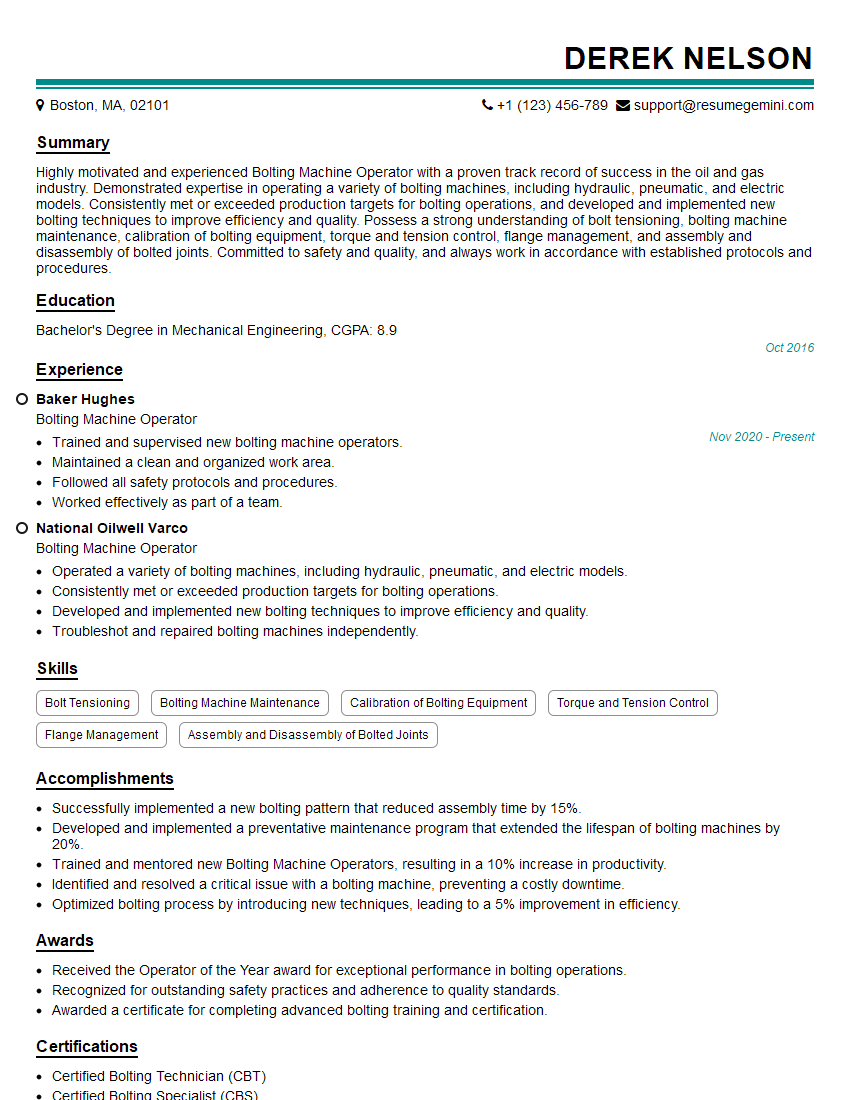

Derek Nelson

Bolting Machine Operator

Summary

Highly motivated and experienced Bolting Machine Operator with a proven track record of success in the oil and gas industry. Demonstrated expertise in operating a variety of bolting machines, including hydraulic, pneumatic, and electric models. Consistently met or exceeded production targets for bolting operations, and developed and implemented new bolting techniques to improve efficiency and quality. Possess a strong understanding of bolt tensioning, bolting machine maintenance, calibration of bolting equipment, torque and tension control, flange management, and assembly and disassembly of bolted joints. Committed to safety and quality, and always work in accordance with established protocols and procedures.

Education

Bachelor’s Degree in Mechanical Engineering

October 2016

Skills

- Bolt Tensioning

- Bolting Machine Maintenance

- Calibration of Bolting Equipment

- Torque and Tension Control

- Flange Management

- Assembly and Disassembly of Bolted Joints

Work Experience

Bolting Machine Operator

- Trained and supervised new bolting machine operators.

- Maintained a clean and organized work area.

- Followed all safety protocols and procedures.

- Worked effectively as part of a team.

Bolting Machine Operator

- Operated a variety of bolting machines, including hydraulic, pneumatic, and electric models.

- Consistently met or exceeded production targets for bolting operations.

- Developed and implemented new bolting techniques to improve efficiency and quality.

- Troubleshot and repaired bolting machines independently.

Accomplishments

- Successfully implemented a new bolting pattern that reduced assembly time by 15%.

- Developed and implemented a preventative maintenance program that extended the lifespan of bolting machines by 20%.

- Trained and mentored new Bolting Machine Operators, resulting in a 10% increase in productivity.

- Identified and resolved a critical issue with a bolting machine, preventing a costly downtime.

- Optimized bolting process by introducing new techniques, leading to a 5% improvement in efficiency.

Awards

- Received the Operator of the Year award for exceptional performance in bolting operations.

- Recognized for outstanding safety practices and adherence to quality standards.

- Awarded a certificate for completing advanced bolting training and certification.

Certificates

- Certified Bolting Technician (CBT)

- Certified Bolting Specialist (CBS)

- American Institute of Steel Construction (AISC) Certification

- National Institute for Certification in Engineering Technologies (NICET) Level I or II for Bolting

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bolting Machine Operator

- Highlight your experience and skills in bolting machine operation, maintenance, and repair.

- Showcase your knowledge of bolt tensioning, torque and tension control, and flange management.

- Provide specific examples of how you have improved efficiency and quality in your previous roles.

- Emphasize your commitment to safety and compliance with industry standards.

- Consider obtaining certifications in bolting machine operation and maintenance to enhance your credibility.

Essential Experience Highlights for a Strong Bolting Machine Operator Resume

- Operated a variety of bolting machines, including hydraulic, pneumatic, and electric models.

- Consistently met or exceeded production targets for bolting operations.

- Developed and implemented new bolting techniques to improve efficiency and quality.

- Troubleshot and repaired bolting machines independently.

- Trained and supervised new bolting machine operators.

- Maintained a clean and organized work area.

- Followed all safety protocols and procedures.

- Worked effectively as part of a team.

Frequently Asked Questions (FAQ’s) For Bolting Machine Operator

What are the key skills and qualifications required to be a successful Bolting Machine Operator?

The key skills and qualifications required to be a successful Bolting Machine Operator include experience in operating and maintaining bolting machines, knowledge of bolt tensioning, torque and tension control, and flange management, and a commitment to safety and compliance with industry standards.

What are the career prospects for Bolting Machine Operators?

Bolting Machine Operators can advance their careers by becoming supervisors or managers, or by specializing in a particular area of bolting, such as flange management or torque and tension control.

What is the average salary for a Bolting Machine Operator?

The average salary for a Bolting Machine Operator in the United States is around $60,000 per year.

What are the working conditions like for Bolting Machine Operators?

Bolting Machine Operators typically work in industrial settings, such as factories or construction sites. The work can be physically demanding, and may involve working in confined spaces or in extreme weather conditions.

What are the safety precautions that Bolting Machine Operators must follow?

Bolting Machine Operators must follow all safety protocols and procedures, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of the potential hazards associated with bolting operations.

What are the opportunities for training and professional development for Bolting Machine Operators?

Bolting Machine Operators can enhance their skills and knowledge through training programs offered by manufacturers, trade associations, and community colleges. They can also obtain certifications in bolting machine operation and maintenance to demonstrate their competence.

What are the key trends and advancements in the bolting industry?

The bolting industry is continually evolving, with new technologies and techniques being developed to improve efficiency, quality, and safety. Some of the key trends and advancements include the use of advanced bolting tools and equipment, the development of new bolting materials, and the adoption of new quality control and inspection methods.