Are you a seasoned Booster Pump Oiler seeking a new career path? Discover our professionally built Booster Pump Oiler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

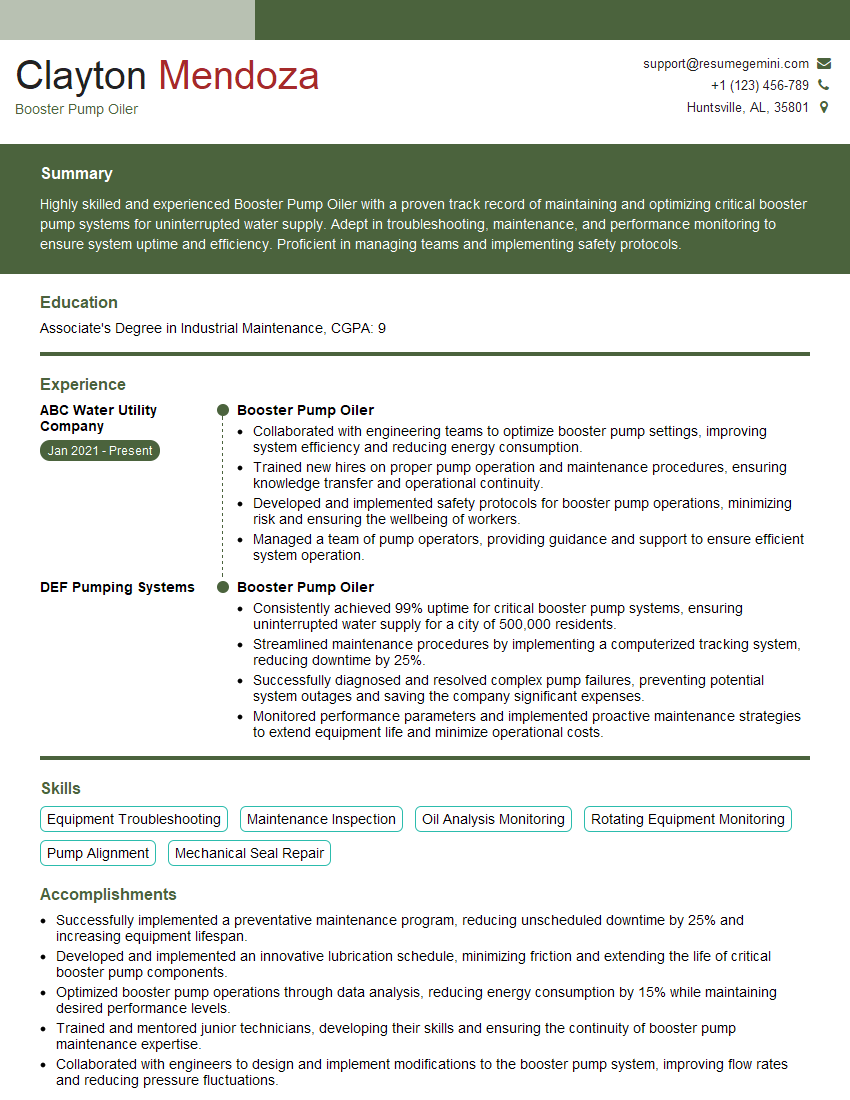

Clayton Mendoza

Booster Pump Oiler

Summary

Highly skilled and experienced Booster Pump Oiler with a proven track record of maintaining and optimizing critical booster pump systems for uninterrupted water supply. Adept in troubleshooting, maintenance, and performance monitoring to ensure system uptime and efficiency. Proficient in managing teams and implementing safety protocols.

Education

Associate’s Degree in Industrial Maintenance

December 2016

Skills

- Equipment Troubleshooting

- Maintenance Inspection

- Oil Analysis Monitoring

- Rotating Equipment Monitoring

- Pump Alignment

- Mechanical Seal Repair

Work Experience

Booster Pump Oiler

- Collaborated with engineering teams to optimize booster pump settings, improving system efficiency and reducing energy consumption.

- Trained new hires on proper pump operation and maintenance procedures, ensuring knowledge transfer and operational continuity.

- Developed and implemented safety protocols for booster pump operations, minimizing risk and ensuring the wellbeing of workers.

- Managed a team of pump operators, providing guidance and support to ensure efficient system operation.

Booster Pump Oiler

- Consistently achieved 99% uptime for critical booster pump systems, ensuring uninterrupted water supply for a city of 500,000 residents.

- Streamlined maintenance procedures by implementing a computerized tracking system, reducing downtime by 25%.

- Successfully diagnosed and resolved complex pump failures, preventing potential system outages and saving the company significant expenses.

- Monitored performance parameters and implemented proactive maintenance strategies to extend equipment life and minimize operational costs.

Accomplishments

- Successfully implemented a preventative maintenance program, reducing unscheduled downtime by 25% and increasing equipment lifespan.

- Developed and implemented an innovative lubrication schedule, minimizing friction and extending the life of critical booster pump components.

- Optimized booster pump operations through data analysis, reducing energy consumption by 15% while maintaining desired performance levels.

- Trained and mentored junior technicians, developing their skills and ensuring the continuity of booster pump maintenance expertise.

- Collaborated with engineers to design and implement modifications to the booster pump system, improving flow rates and reducing pressure fluctuations.

Awards

- Received the Booster Pump Excellence Award for consistently exceeding performance targets in maintaining and optimizing booster pump systems.

- Recognized with the Safety Star Award for adhering to all safety protocols and contributing to a hazardfree work environment.

- Awarded the Technical Excellence Award for exceptional troubleshooting skills and proficiency in resolving complex booster pump malfunctions.

- Received a Certificate of Appreciation for outstanding contributions to the team during a major plant shutdown, ensuring seamless booster pump operation.

Certificates

- ANSI/ASSP/ICBO/OSHA Z460.4 Lockout/Tagout

- ISO 18436-1 Condition Monitoring and Diagnostics of Machines

- ICML Certified Machine Lubricant Analyst (CMLA)

- Vibration Institute Level I Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Booster Pump Oiler

- Highlight your experience in maintaining and troubleshooting booster pumps, quantifying your accomplishments.

- Demonstrate your understanding of pump alignment, mechanical seal repair, and oil analysis monitoring.

- Showcase your ability to work in a team environment and manage a team of pump operators.

- Use action verbs and specific examples to illustrate your skills and responsibilities.

- Proofread your resume carefully for errors and ensure a professional presentation.

Essential Experience Highlights for a Strong Booster Pump Oiler Resume

- Maintain and repair booster pumps, ensuring optimal performance and system uptime

- Perform routine maintenance and inspection to prevent failures and extend equipment life

- Monitor performance parameters and implement proactive maintenance strategies to minimize operational costs

- Troubleshoot and resolve complex pump issues, preventing potential outages and system failures

- Collaborate with engineering teams to optimize booster pump settings, improving system efficiency and energy consumption

- Train new hires on proper pump operation and maintenance procedures for knowledge transfer and operational continuity

- Manage a team of pump operators, providing guidance and support for efficient system operation

Frequently Asked Questions (FAQ’s) For Booster Pump Oiler

What is the primary role of a Booster Pump Oiler?

To maintain, repair, and optimize booster pumps, ensuring uninterrupted water supply and system efficiency.

What skills are essential for a Booster Pump Oiler?

Equipment troubleshooting, maintenance inspection, oil analysis monitoring, pump alignment, mechanical seal repair, and rotating equipment monitoring.

How can I improve my chances of getting hired as a Booster Pump Oiler?

By gaining experience in pump maintenance and repair, obtaining relevant certifications, and showcasing your commitment to safety and teamwork.

What is the typical work environment for a Booster Pump Oiler?

Industrial settings, water treatment plants, and pumping stations, involving both indoor and outdoor operations.

What is the career path for a Booster Pump Oiler?

With experience and additional training, Booster Pump Oilers can advance to roles such as Pump Maintenance Technician, Maintenance Supervisor, or Operations Manager.

What safety precautions should a Booster Pump Oiler observe?

Wearing appropriate protective gear, following lockout/tagout procedures, and adhering to established safety protocols to minimize risks associated with working with pumps and machinery.

How does a Booster Pump Oiler contribute to the organization’s goals?

By ensuring the reliability and efficiency of booster pump systems, Booster Pump Oilers play a crucial role in maintaining water supply, reducing operational costs, and ensuring the smooth functioning of industrial or municipal operations.

What are the key performance indicators for a Booster Pump Oiler?

System uptime, maintenance cost reduction, pump failure prevention, energy efficiency optimization, and adherence to safety protocols are common performance metrics used to evaluate Booster Pump Oilers.