Are you a seasoned Bore Mill Operator seeking a new career path? Discover our professionally built Bore Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

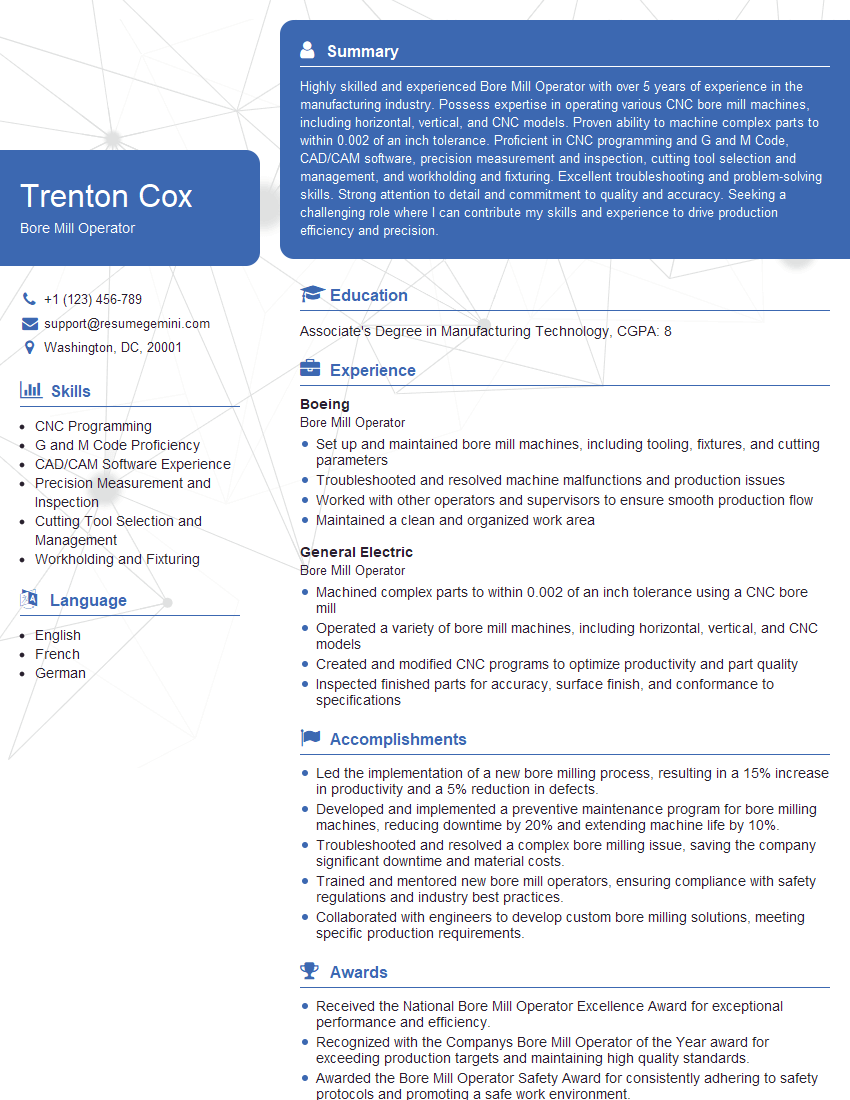

Trenton Cox

Bore Mill Operator

Summary

Highly skilled and experienced Bore Mill Operator with over 5 years of experience in the manufacturing industry. Possess expertise in operating various CNC bore mill machines, including horizontal, vertical, and CNC models. Proven ability to machine complex parts to within 0.002 of an inch tolerance. Proficient in CNC programming and G and M Code, CAD/CAM software, precision measurement and inspection, cutting tool selection and management, and workholding and fixturing. Excellent troubleshooting and problem-solving skills. Strong attention to detail and commitment to quality and accuracy. Seeking a challenging role where I can contribute my skills and experience to drive production efficiency and precision.

Education

Associate’s Degree in Manufacturing Technology

February 2018

Skills

- CNC Programming

- G and M Code Proficiency

- CAD/CAM Software Experience

- Precision Measurement and Inspection

- Cutting Tool Selection and Management

- Workholding and Fixturing

Work Experience

Bore Mill Operator

- Set up and maintained bore mill machines, including tooling, fixtures, and cutting parameters

- Troubleshooted and resolved machine malfunctions and production issues

- Worked with other operators and supervisors to ensure smooth production flow

- Maintained a clean and organized work area

Bore Mill Operator

- Machined complex parts to within 0.002 of an inch tolerance using a CNC bore mill

- Operated a variety of bore mill machines, including horizontal, vertical, and CNC models

- Created and modified CNC programs to optimize productivity and part quality

- Inspected finished parts for accuracy, surface finish, and conformance to specifications

Accomplishments

- Led the implementation of a new bore milling process, resulting in a 15% increase in productivity and a 5% reduction in defects.

- Developed and implemented a preventive maintenance program for bore milling machines, reducing downtime by 20% and extending machine life by 10%.

- Troubleshooted and resolved a complex bore milling issue, saving the company significant downtime and material costs.

- Trained and mentored new bore mill operators, ensuring compliance with safety regulations and industry best practices.

- Collaborated with engineers to develop custom bore milling solutions, meeting specific production requirements.

Awards

- Received the National Bore Mill Operator Excellence Award for exceptional performance and efficiency.

- Recognized with the Companys Bore Mill Operator of the Year award for exceeding production targets and maintaining high quality standards.

- Awarded the Bore Mill Operator Safety Award for consistently adhering to safety protocols and promoting a safe work environment.

Certificates

- CNC Operator Certification

- G-Code Programming Certification

- Precision Measurement Certification

- OSHPD 10-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bore Mill Operator

- Highlight your experience and skills in CNC programming and G and M Code.

- Quantify your accomplishments and provide specific examples of your work.

- Demonstrate your knowledge of CAD/CAM software and precision measurement and inspection techniques.

- Emphasize your troubleshooting and problem-solving abilities.

Essential Experience Highlights for a Strong Bore Mill Operator Resume

- Operated a variety of bore mill machines to machine complex parts to within 0.002 of an inch tolerance.

- Created and modified CNC programs to optimize productivity and part quality.

- Inspected finished parts for accuracy, surface finish, and conformance to specifications.

- Set up and maintained bore mill machines, including tooling, fixtures, and cutting parameters.

- Troubleshooted and resolved machine malfunctions and production issues.

Frequently Asked Questions (FAQ’s) For Bore Mill Operator

What are the key skills and qualifications required to be a Bore Mill Operator?

The key skills and qualifications required to be a Bore Mill Operator include proficiency in CNC programming, G and M Code, CAD/CAM software, precision measurement and inspection, cutting tool selection and management, and workholding and fixturing.

What are the primary responsibilities of a Bore Mill Operator?

The primary responsibilities of a Bore Mill Operator include machining complex parts to within specified tolerances, creating and modifying CNC programs, inspecting finished parts, setting up and maintaining bore mill machines, and troubleshooting machine malfunctions and production issues.

What are the different types of bore mill machines?

There are different types of bore mill machines, including horizontal bore mills, vertical bore mills, and CNC bore mills.

What is the role of a Bore Mill Operator in the manufacturing process?

Bore Mill Operators play a crucial role in the manufacturing process by producing complex parts with high precision and accuracy using bore mill machines.

What are the career prospects for Bore Mill Operators?

Bore Mill Operators with the right skills and experience can advance to roles such as CNC programmers, manufacturing supervisors, and quality control inspectors.