Are you a seasoned Borematic Operator seeking a new career path? Discover our professionally built Borematic Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

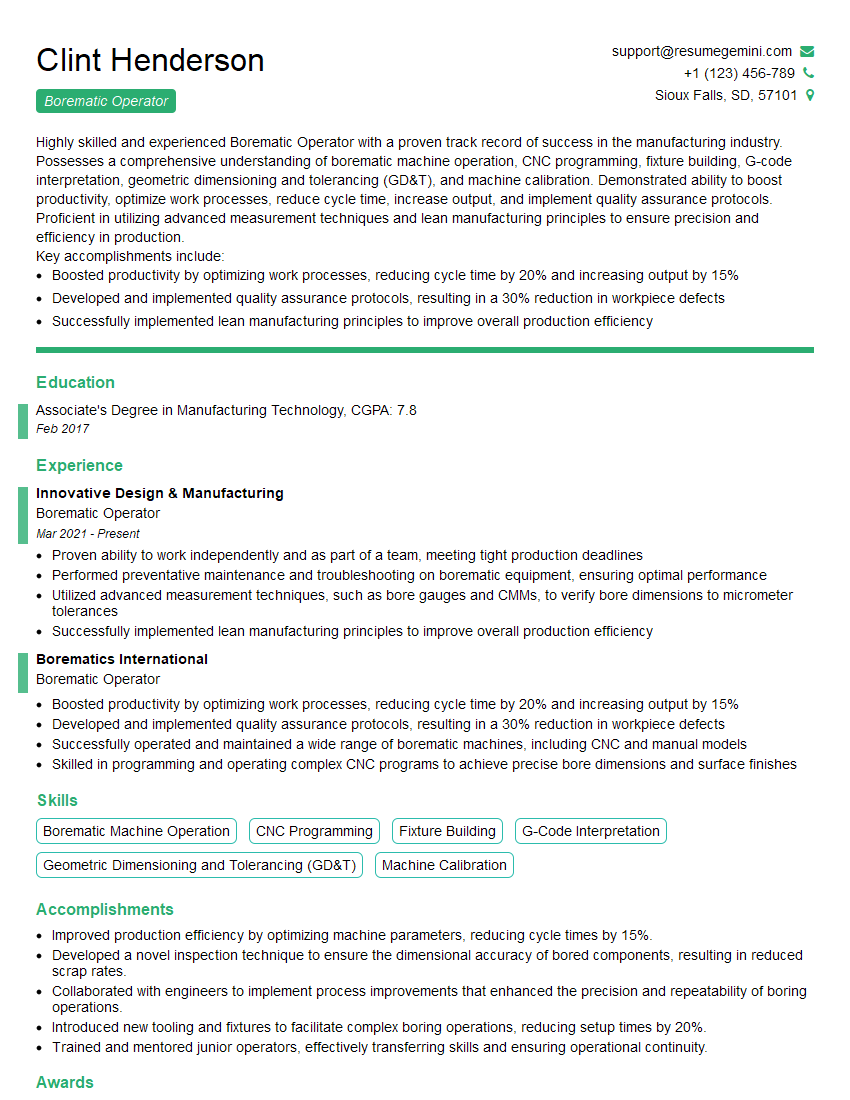

Clint Henderson

Borematic Operator

Summary

Highly skilled and experienced Borematic Operator with a proven track record of success in the manufacturing industry. Possesses a comprehensive understanding of borematic machine operation, CNC programming, fixture building, G-code interpretation, geometric dimensioning and tolerancing (GD&T), and machine calibration. Demonstrated ability to boost productivity, optimize work processes, reduce cycle time, increase output, and implement quality assurance protocols. Proficient in utilizing advanced measurement techniques and lean manufacturing principles to ensure precision and efficiency in production.

Key accomplishments include:

- Boosted productivity by optimizing work processes, reducing cycle time by 20% and increasing output by 15%

- Developed and implemented quality assurance protocols, resulting in a 30% reduction in workpiece defects

- Successfully implemented lean manufacturing principles to improve overall production efficiency

Education

Associate’s Degree in Manufacturing Technology

February 2017

Skills

- Borematic Machine Operation

- CNC Programming

- Fixture Building

- G-Code Interpretation

- Geometric Dimensioning and Tolerancing (GD&T)

- Machine Calibration

Work Experience

Borematic Operator

- Proven ability to work independently and as part of a team, meeting tight production deadlines

- Performed preventative maintenance and troubleshooting on borematic equipment, ensuring optimal performance

- Utilized advanced measurement techniques, such as bore gauges and CMMs, to verify bore dimensions to micrometer tolerances

- Successfully implemented lean manufacturing principles to improve overall production efficiency

Borematic Operator

- Boosted productivity by optimizing work processes, reducing cycle time by 20% and increasing output by 15%

- Developed and implemented quality assurance protocols, resulting in a 30% reduction in workpiece defects

- Successfully operated and maintained a wide range of borematic machines, including CNC and manual models

- Skilled in programming and operating complex CNC programs to achieve precise bore dimensions and surface finishes

Accomplishments

- Improved production efficiency by optimizing machine parameters, reducing cycle times by 15%.

- Developed a novel inspection technique to ensure the dimensional accuracy of bored components, resulting in reduced scrap rates.

- Collaborated with engineers to implement process improvements that enhanced the precision and repeatability of boring operations.

- Introduced new tooling and fixtures to facilitate complex boring operations, reducing setup times by 20%.

- Trained and mentored junior operators, effectively transferring skills and ensuring operational continuity.

Awards

- Awarded Borematic Operator of the Year for exceptional performance in precision boring operations.

- Recognized for achieving a 99.9% accuracy rate in critical bore dimensions, exceeding industry standards.

- Received Excellence in Borematic Machining award for consistently delivering highquality components within tight tolerances.

- Honored with Safety Champion award for maintaining a safe and incidentfree work environment.

Certificates

- Certified Borematic Operator (CBO)

- CNC Programming Certificate

- GD&T Certification

- Metrology Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Borematic Operator

- Highlight your skills and experience in borematic machine operation, CNC programming, and quality assurance.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Demonstrate your attention to detail and commitment to precision in your resume.

- Proofread your resume carefully for any errors before submitting it to potential employers.

Essential Experience Highlights for a Strong Borematic Operator Resume

- Operate and maintain borematic machines, including CNC and manual models

- Program and operate complex CNC programs to achieve precise bore dimensions and surface finishes

- Perform preventative maintenance and troubleshooting on borematic equipment to ensure optimal performance

- Utilize advanced measurement techniques, such as bore gauges and CMMs, to verify bore dimensions to micrometer tolerances

- Inspect and verify the quality of machined parts to ensure they meet specifications

- Maintain a clean and organized work area, following safety protocols and adhering to quality standards

Frequently Asked Questions (FAQ’s) For Borematic Operator

What is a borematic operator?

A borematic operator is a skilled machinist who operates borematic machines to create precise bores in metal parts. Borematic machines are used in a variety of industries, including automotive, aerospace, and medical.

What skills are required to be a borematic operator?

Borematic operators need to have a strong understanding of machining principles, as well as experience in operating CNC machines. They also need to be able to read and interpret blueprints and have a good eye for detail.

What is the job outlook for borematic operators?

The job outlook for borematic operators is expected to be good over the next few years. As the manufacturing industry continues to grow, there will be a need for skilled machinists to operate borematic machines.

What are the career advancement opportunities for borematic operators?

Borematic operators can advance to positions such as lead operator, supervisor, or quality control inspector. With additional training, they may also be able to move into engineering or management positions.

What is the average salary for a borematic operator?

The average salary for a borematic operator is around $25 per hour. However, salaries can vary depending on experience, location, and industry.

What are the working conditions for borematic operators?

Borematic operators typically work in a manufacturing environment. They may be exposed to noise, dust, and other hazards. However, most workplaces have safety protocols in place to protect workers.

What are the benefits of being a borematic operator?

Borematic operators can enjoy a number of benefits, including job security, competitive pay, and the opportunity to learn new skills. They may also have the opportunity to work with cutting-edge technology.