Are you a seasoned Brake Press Operator seeking a new career path? Discover our professionally built Brake Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

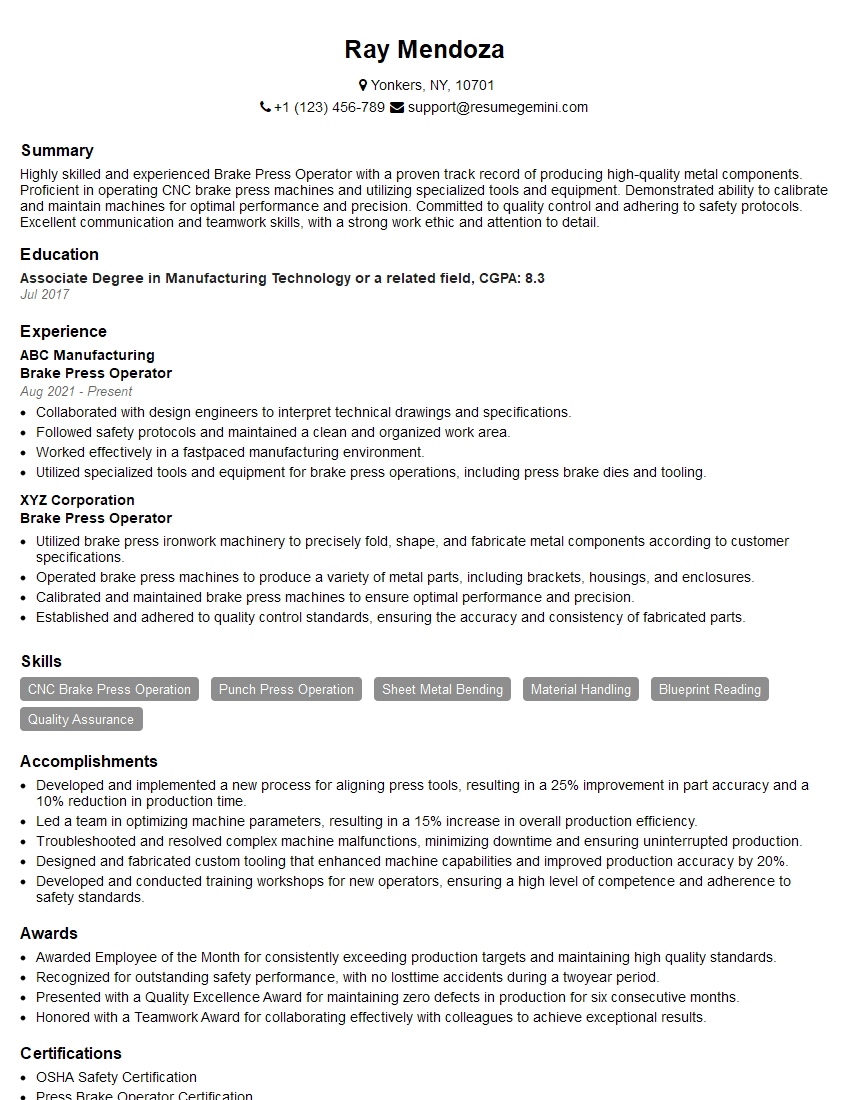

Ray Mendoza

Brake Press Operator

Summary

Highly skilled and experienced Brake Press Operator with a proven track record of producing high-quality metal components. Proficient in operating CNC brake press machines and utilizing specialized tools and equipment. Demonstrated ability to calibrate and maintain machines for optimal performance and precision. Committed to quality control and adhering to safety protocols. Excellent communication and teamwork skills, with a strong work ethic and attention to detail.

Education

Associate Degree in Manufacturing Technology or a related field

July 2017

Skills

- CNC Brake Press Operation

- Punch Press Operation

- Sheet Metal Bending

- Material Handling

- Blueprint Reading

- Quality Assurance

Work Experience

Brake Press Operator

- Collaborated with design engineers to interpret technical drawings and specifications.

- Followed safety protocols and maintained a clean and organized work area.

- Worked effectively in a fastpaced manufacturing environment.

- Utilized specialized tools and equipment for brake press operations, including press brake dies and tooling.

Brake Press Operator

- Utilized brake press ironwork machinery to precisely fold, shape, and fabricate metal components according to customer specifications.

- Operated brake press machines to produce a variety of metal parts, including brackets, housings, and enclosures.

- Calibrated and maintained brake press machines to ensure optimal performance and precision.

- Established and adhered to quality control standards, ensuring the accuracy and consistency of fabricated parts.

Accomplishments

- Developed and implemented a new process for aligning press tools, resulting in a 25% improvement in part accuracy and a 10% reduction in production time.

- Led a team in optimizing machine parameters, resulting in a 15% increase in overall production efficiency.

- Troubleshooted and resolved complex machine malfunctions, minimizing downtime and ensuring uninterrupted production.

- Designed and fabricated custom tooling that enhanced machine capabilities and improved production accuracy by 20%.

- Developed and conducted training workshops for new operators, ensuring a high level of competence and adherence to safety standards.

Awards

- Awarded Employee of the Month for consistently exceeding production targets and maintaining high quality standards.

- Recognized for outstanding safety performance, with no losttime accidents during a twoyear period.

- Presented with a Quality Excellence Award for maintaining zero defects in production for six consecutive months.

- Honored with a Teamwork Award for collaborating effectively with colleagues to achieve exceptional results.

Certificates

- OSHA Safety Certification

- Press Brake Operator Certification

- Quality Assurance Certification (optional)

- Lean Manufacturing Certification (optional)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brake Press Operator

- Highlight your experience and skills in operating CNC brake press machines.

- Showcase your knowledge of quality control standards and your commitment to accuracy and precision.

- Emphasize your ability to work effectively in a fast-paced manufacturing environment.

- Demonstrate your understanding of safety protocols and your commitment to maintaining a safe work environment.

Essential Experience Highlights for a Strong Brake Press Operator Resume

- Operated brake press machines to fabricate metal parts according to customer specifications.

- Calibrated and maintained brake press machines to ensure optimal performance and accuracy.

- Established and adhered to quality control standards, ensuring the accuracy and consistency of fabricated parts.

- Collaborated with design engineers to interpret technical drawings and specifications.

- Followed safety protocols and maintained a clean and organized work area.

- Worked effectively in a fast-paced manufacturing environment.

- Utilized specialized tools and equipment for brake press operations, including press brake dies and tooling.

Frequently Asked Questions (FAQ’s) For Brake Press Operator

What is a Brake Press Operator?

A Brake Press Operator is responsible for operating brake press machines to shape and form metal components according to customer specifications. They ensure that the machines are calibrated and maintained for optimal performance, and that the finished parts meet quality standards.

What skills are required to be a successful Brake Press Operator?

Successful Brake Press Operators typically have a strong understanding of metalworking principles, including bending, forming, and fabrication techniques. They are proficient in operating CNC brake press machines and utilizing specialized tools and equipment. Additionally, they possess excellent attention to detail, quality control skills, and a commitment to safety.

What are the career prospects for Brake Press Operators?

Brake Press Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They may also specialize in operating specific types of brake press machines or in working with particular materials. With experience, they can also move into roles such as quality control inspectors or design engineers.

What is the work environment of a Brake Press Operator like?

Brake Press Operators typically work in manufacturing facilities, where they operate brake press machines to fabricate metal components. The work environment can be noisy and fast-paced, and may involve working with heavy machinery and materials. However, many Brake Press Operators enjoy the satisfaction of working with their hands and creating tangible products.

What are the safety precautions that Brake Press Operators must follow?

Brake Press Operators must follow strict safety protocols to prevent accidents and injuries. These protocols include wearing appropriate safety gear, such as gloves, safety glasses, and earplugs. They must also be aware of the potential hazards associated with operating heavy machinery, such as pinch points and sharp edges.