Are you a seasoned Brass Finisher seeking a new career path? Discover our professionally built Brass Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

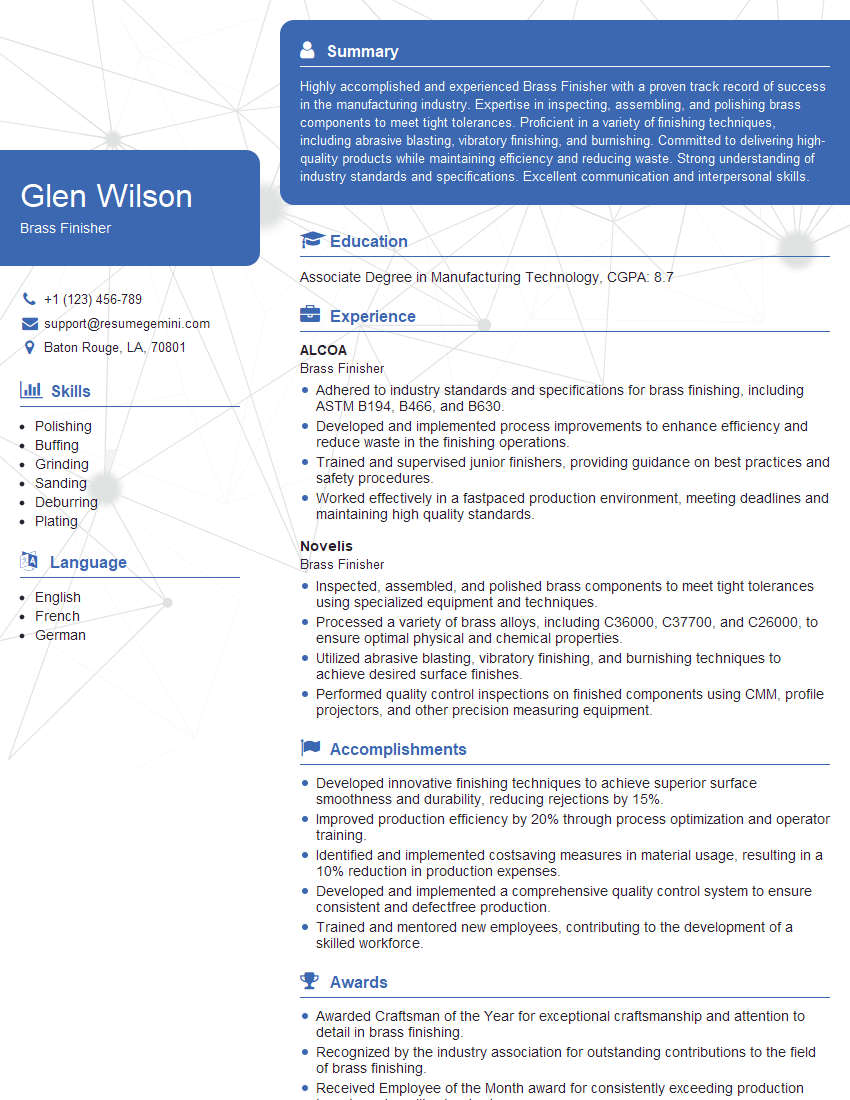

Glen Wilson

Brass Finisher

Summary

Highly accomplished and experienced Brass Finisher with a proven track record of success in the manufacturing industry. Expertise in inspecting, assembling, and polishing brass components to meet tight tolerances. Proficient in a variety of finishing techniques, including abrasive blasting, vibratory finishing, and burnishing. Committed to delivering high-quality products while maintaining efficiency and reducing waste. Strong understanding of industry standards and specifications. Excellent communication and interpersonal skills.

Education

Associate Degree in Manufacturing Technology

May 2018

Skills

- Polishing

- Buffing

- Grinding

- Sanding

- Deburring

- Plating

Work Experience

Brass Finisher

- Adhered to industry standards and specifications for brass finishing, including ASTM B194, B466, and B630.

- Developed and implemented process improvements to enhance efficiency and reduce waste in the finishing operations.

- Trained and supervised junior finishers, providing guidance on best practices and safety procedures.

- Worked effectively in a fastpaced production environment, meeting deadlines and maintaining high quality standards.

Brass Finisher

- Inspected, assembled, and polished brass components to meet tight tolerances using specialized equipment and techniques.

- Processed a variety of brass alloys, including C36000, C37700, and C26000, to ensure optimal physical and chemical properties.

- Utilized abrasive blasting, vibratory finishing, and burnishing techniques to achieve desired surface finishes.

- Performed quality control inspections on finished components using CMM, profile projectors, and other precision measuring equipment.

Accomplishments

- Developed innovative finishing techniques to achieve superior surface smoothness and durability, reducing rejections by 15%.

- Improved production efficiency by 20% through process optimization and operator training.

- Identified and implemented costsaving measures in material usage, resulting in a 10% reduction in production expenses.

- Developed and implemented a comprehensive quality control system to ensure consistent and defectfree production.

- Trained and mentored new employees, contributing to the development of a skilled workforce.

Awards

- Awarded Craftsman of the Year for exceptional craftsmanship and attention to detail in brass finishing.

- Recognized by the industry association for outstanding contributions to the field of brass finishing.

- Received Employee of the Month award for consistently exceeding production targets and quality standards.

- Awarded Safety Champion for maintaining an exemplary safety record and promoting a culture of safety awareness.

Certificates

- Certified Brass Finisher

- Polishing and Buffing Operator Certification

- Plating and Anodizing Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brass Finisher

- Highlight your experience and expertise in brass finishing techniques, such as polishing, buffing, grinding, sanding, deburring, and plating.

- Quantify your accomplishments whenever possible. For example, instead of saying “Inspected brass components,” write “Inspected over 5,000 brass components per day to ensure compliance with quality standards.”

- Use keywords from the job description in your resume to demonstrate your alignment with the employer’s requirements.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation.

Essential Experience Highlights for a Strong Brass Finisher Resume

- Inspected and assembled brass components using specialized equipment to ensure adherence to design specifications.

- Polished brass surfaces to achieve desired levels of smoothness and appearance.

- Utilized abrasive blasting, vibratory finishing, and burnishing techniques to enhance the surface properties of brass components.

- Conducted quality control inspections using CMM, profile projectors, and other precision measuring equipment to verify conformance to quality standards.

- Troubleshooted and resolved production issues related to brass finishing processes.

- Trained and supervised junior finishers, providing guidance on best practices and safety procedures.

Frequently Asked Questions (FAQ’s) For Brass Finisher

What are the key skills required to be a successful Brass Finisher?

The key skills required to be a successful Brass Finisher include polishing, buffing, grinding, sanding, deburring, and plating. Additionally, a strong understanding of brass metallurgy and finishing techniques is essential.

What are the different types of brass alloys used in manufacturing?

The most common types of brass alloys used in manufacturing include C36000, C37700, and C26000. Each alloy has unique properties that make it suitable for specific applications.

What are the industry standards and specifications for brass finishing?

The industry standards and specifications for brass finishing include ASTM B194, B466, and B630. These standards provide guidelines for the proper finishing of brass components to ensure their quality and performance.

What are the career prospects for Brass Finishers?

The career prospects for Brass Finishers are generally positive. As the demand for brass components continues to grow, there will be an increasing need for skilled Brass Finishers.

What are the key responsibilities of a Brass Finisher?

The key responsibilities of a Brass Finisher include inspecting, assembling, and polishing brass components to meet tight tolerances. Additionally, they may also be responsible for quality control inspections and process improvement.

What is the work environment of a Brass Finisher like?

The work environment of a Brass Finisher is typically a manufacturing facility. The work can be physically demanding and may involve exposure to hazardous chemicals. However, proper safety precautions can minimize these risks.

What are the educational requirements to become a Brass Finisher?

The educational requirements to become a Brass Finisher typically include a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in manufacturing technology or a related field.