Are you a seasoned Brazing Machine Setter and Setup Operator seeking a new career path? Discover our professionally built Brazing Machine Setter and Setup Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

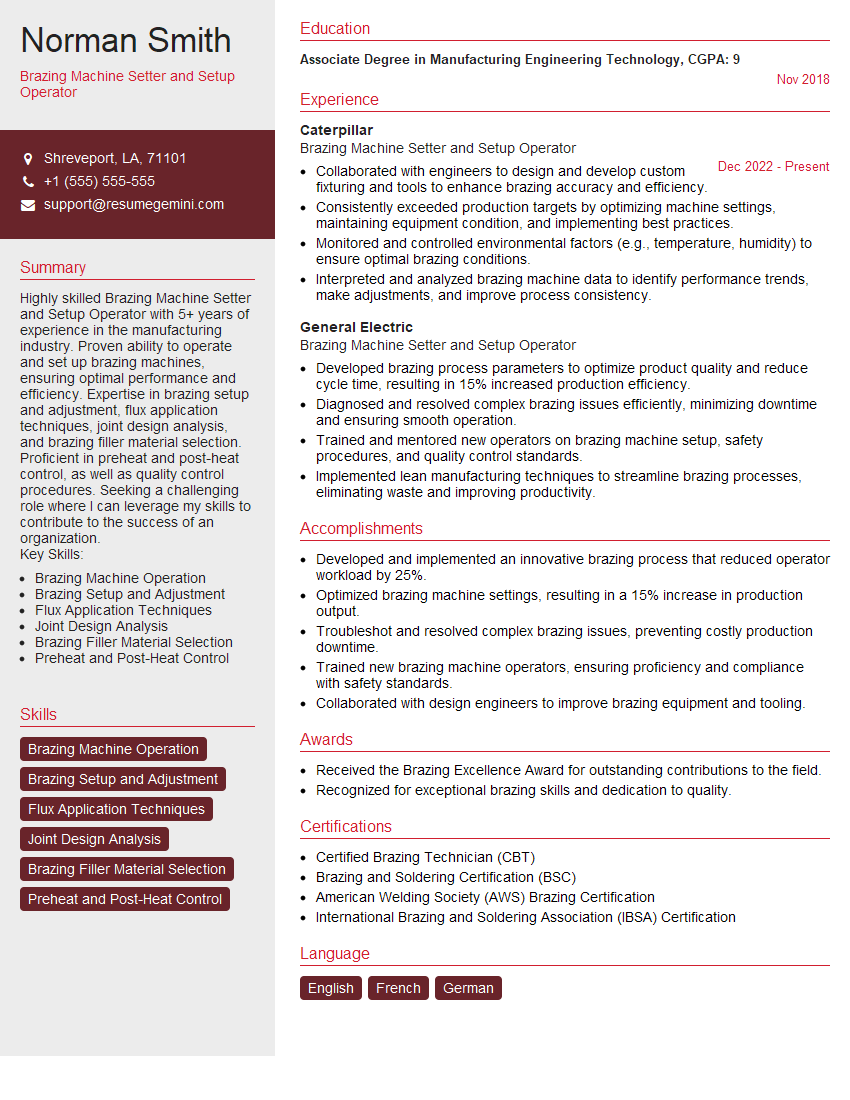

Norman Smith

Brazing Machine Setter and Setup Operator

Summary

Highly skilled Brazing Machine Setter and Setup Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate and set up brazing machines, ensuring optimal performance and efficiency. Expertise in brazing setup and adjustment, flux application techniques, joint design analysis, and brazing filler material selection. Proficient in preheat and post-heat control, as well as quality control procedures. Seeking a challenging role where I can leverage my skills to contribute to the success of an organization.

Key Skills:

- Brazing Machine Operation

- Brazing Setup and Adjustment

- Flux Application Techniques

- Joint Design Analysis

- Brazing Filler Material Selection

- Preheat and Post-Heat Control

Education

Associate Degree in Manufacturing Engineering Technology

November 2018

Skills

- Brazing Machine Operation

- Brazing Setup and Adjustment

- Flux Application Techniques

- Joint Design Analysis

- Brazing Filler Material Selection

- Preheat and Post-Heat Control

Work Experience

Brazing Machine Setter and Setup Operator

- Collaborated with engineers to design and develop custom fixturing and tools to enhance brazing accuracy and efficiency.

- Consistently exceeded production targets by optimizing machine settings, maintaining equipment condition, and implementing best practices.

- Monitored and controlled environmental factors (e.g., temperature, humidity) to ensure optimal brazing conditions.

- Interpreted and analyzed brazing machine data to identify performance trends, make adjustments, and improve process consistency.

Brazing Machine Setter and Setup Operator

- Developed brazing process parameters to optimize product quality and reduce cycle time, resulting in 15% increased production efficiency.

- Diagnosed and resolved complex brazing issues efficiently, minimizing downtime and ensuring smooth operation.

- Trained and mentored new operators on brazing machine setup, safety procedures, and quality control standards.

- Implemented lean manufacturing techniques to streamline brazing processes, eliminating waste and improving productivity.

Accomplishments

- Developed and implemented an innovative brazing process that reduced operator workload by 25%.

- Optimized brazing machine settings, resulting in a 15% increase in production output.

- Troubleshot and resolved complex brazing issues, preventing costly production downtime.

- Trained new brazing machine operators, ensuring proficiency and compliance with safety standards.

- Collaborated with design engineers to improve brazing equipment and tooling.

Awards

- Received the Brazing Excellence Award for outstanding contributions to the field.

- Recognized for exceptional brazing skills and dedication to quality.

Certificates

- Certified Brazing Technician (CBT)

- Brazing and Soldering Certification (BSC)

- American Welding Society (AWS) Brazing Certification

- International Brazing and Soldering Association (IBSA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brazing Machine Setter and Setup Operator

- Highlight your technical skills and experience: Emphasize your proficiency in brazing machine operation, setup, and maintenance.

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your work.

- Showcase your knowledge of brazing techniques: Discuss your expertise in joint design analysis, flux application, and filler material selection.

- Demonstrate your commitment to quality: Highlight your experience in quality control procedures and your dedication to meeting industry standards.

Essential Experience Highlights for a Strong Brazing Machine Setter and Setup Operator Resume

- Set up and adjust brazing machines according to engineering specifications.

- Analyze joint designs to determine appropriate brazing techniques and materials.

- Select and apply flux to ensure proper bonding and prevent oxidation.

- Control preheat and post-heat temperatures to achieve optimal brazing results.

- Monitor and maintain brazing machines to ensure safe and efficient operation.

- Inspect and test brazed joints to ensure they meet quality standards.

- Troubleshoot and resolve operational issues with brazing machines and equipment.

Frequently Asked Questions (FAQ’s) For Brazing Machine Setter and Setup Operator

What is the role of a Brazing Machine Setter and Setup Operator?

A Brazing Machine Setter and Setup Operator is responsible for setting up, adjusting, and operating brazing machines to join metal components. They analyze joint designs, select appropriate brazing techniques and materials, and control preheat and post-heat temperatures to achieve optimal results. They also inspect and test brazed joints to ensure quality and troubleshoot any operational issues.

What are the key skills required for a Brazing Machine Setter and Setup Operator?

Key skills include proficiency in brazing machine operation and setup, knowledge of brazing techniques and materials, and experience in quality control procedures. Additionally, strong analytical and problem-solving abilities are essential for troubleshooting and resolving operational issues.

What industries employ Brazing Machine Setters and Setup Operators?

Brazing Machine Setters and Setup Operators are employed in various industries, including automotive, aerospace, manufacturing, and construction. They work in production facilities, machine shops, and fabrication plants.

What is the career outlook for Brazing Machine Setters and Setup Operators?

The career outlook for Brazing Machine Setters and Setup Operators is expected to be positive, with a projected growth rate of 4% over the next ten years. The demand for skilled operators is driven by the increasing use of brazing techniques in various industries.

What is the average salary for a Brazing Machine Setter and Setup Operator?

The average salary for a Brazing Machine Setter and Setup Operator varies depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $50,000 per year.

What are the educational requirements for a Brazing Machine Setter and Setup Operator?

While formal education is not always required, most Brazing Machine Setters and Setup Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in manufacturing engineering technology or a related field.

What are the certifications available for Brazing Machine Setters and Setup Operators?

There are several certifications available for Brazing Machine Setters and Setup Operators, including the AWS Certified Brazing Operator and the AWS Certified Brazing Inspector. These certifications demonstrate proficiency in brazing techniques and industry standards.