Are you a seasoned Break Down Operator seeking a new career path? Discover our professionally built Break Down Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

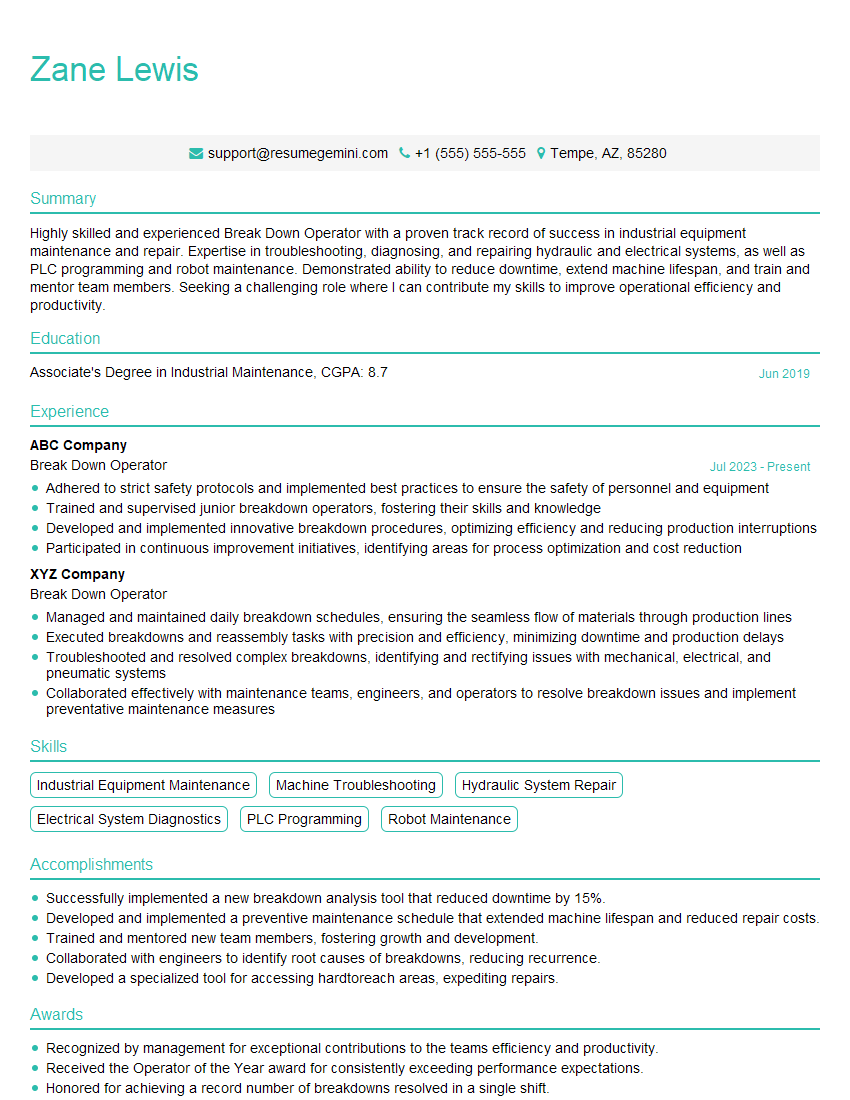

Zane Lewis

Break Down Operator

Summary

Highly skilled and experienced Break Down Operator with a proven track record of success in industrial equipment maintenance and repair. Expertise in troubleshooting, diagnosing, and repairing hydraulic and electrical systems, as well as PLC programming and robot maintenance. Demonstrated ability to reduce downtime, extend machine lifespan, and train and mentor team members. Seeking a challenging role where I can contribute my skills to improve operational efficiency and productivity.

Education

Associate’s Degree in Industrial Maintenance

June 2019

Skills

- Industrial Equipment Maintenance

- Machine Troubleshooting

- Hydraulic System Repair

- Electrical System Diagnostics

- PLC Programming

- Robot Maintenance

Work Experience

Break Down Operator

- Adhered to strict safety protocols and implemented best practices to ensure the safety of personnel and equipment

- Trained and supervised junior breakdown operators, fostering their skills and knowledge

- Developed and implemented innovative breakdown procedures, optimizing efficiency and reducing production interruptions

- Participated in continuous improvement initiatives, identifying areas for process optimization and cost reduction

Break Down Operator

- Managed and maintained daily breakdown schedules, ensuring the seamless flow of materials through production lines

- Executed breakdowns and reassembly tasks with precision and efficiency, minimizing downtime and production delays

- Troubleshooted and resolved complex breakdowns, identifying and rectifying issues with mechanical, electrical, and pneumatic systems

- Collaborated effectively with maintenance teams, engineers, and operators to resolve breakdown issues and implement preventative maintenance measures

Accomplishments

- Successfully implemented a new breakdown analysis tool that reduced downtime by 15%.

- Developed and implemented a preventive maintenance schedule that extended machine lifespan and reduced repair costs.

- Trained and mentored new team members, fostering growth and development.

- Collaborated with engineers to identify root causes of breakdowns, reducing recurrence.

- Developed a specialized tool for accessing hardtoreach areas, expediting repairs.

Awards

- Recognized by management for exceptional contributions to the teams efficiency and productivity.

- Received the Operator of the Year award for consistently exceeding performance expectations.

- Honored for achieving a record number of breakdowns resolved in a single shift.

- Recognized for exemplary safety practices and adherence to protocols.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Industrial Maintenance Mechanic (CIMM)

- Robotics Maintenance Technician Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Break Down Operator

- Highlight your experience and skills in industrial equipment maintenance and repair.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your ability to work independently and as part of a team.

- Showcase your problem-solving skills and ability to identify and resolve root causes of breakdowns.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Break Down Operator Resume

- Perform routine maintenance and repairs on industrial equipment, including hydraulic and electrical systems.

- Troubleshoot and diagnose equipment breakdowns, identifying root causes and implementing solutions.

- Repair and replace faulty components, ensuring optimal performance and uptime.

- Conduct preventive maintenance, including lubrication, adjustments, and inspections, to extend machine lifespan and reduce repair costs.

- Collaborate with engineers and other maintenance personnel to resolve complex technical issues.

- Train and mentor new team members, fostering their growth and development.

- Maintain a safe and organized work environment, adhering to all safety regulations.

Frequently Asked Questions (FAQ’s) For Break Down Operator

What is the role of a Break Down Operator?

A Break Down Operator is responsible for maintaining and repairing industrial equipment, ensuring optimal performance and minimizing downtime.

What skills are required to be a successful Break Down Operator?

Successful Break Down Operators typically have strong skills in industrial equipment maintenance, troubleshooting, electrical and hydraulic system repair, and PLC programming.

What is the typical work environment for a Break Down Operator?

Break Down Operators typically work in industrial settings, such as manufacturing plants, warehouses, and construction sites.

What is the career outlook for Break Down Operators?

The career outlook for Break Down Operators is expected to be good, as the demand for skilled maintenance technicians continues to grow.

What are the earning prospects for Break Down Operators?

The earning prospects for Break Down Operators vary depending on experience, location, and industry. However, experienced Break Down Operators can earn a competitive salary.

What are the challenges faced by Break Down Operators?

Break Down Operators may face challenges such as working in demanding environments, dealing with complex technical issues, and meeting production deadlines.

What are the opportunities for career advancement for Break Down Operators?

With experience and additional training, Break Down Operators can advance to roles such as Maintenance Supervisor, Maintenance Manager, or Plant Engineer.