Are you a seasoned Breaking Machine Operator seeking a new career path? Discover our professionally built Breaking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

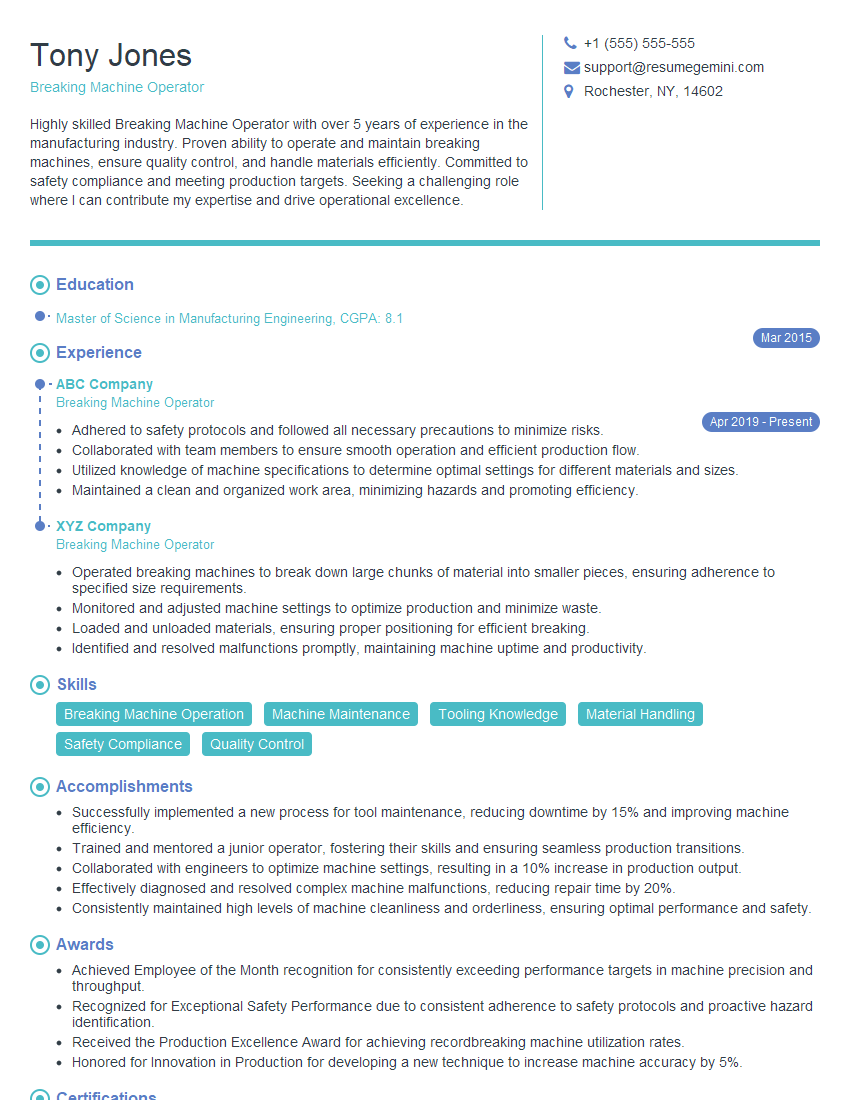

Tony Jones

Breaking Machine Operator

Summary

Highly skilled Breaking Machine Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate and maintain breaking machines, ensure quality control, and handle materials efficiently. Committed to safety compliance and meeting production targets. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Master of Science in Manufacturing Engineering

March 2015

Skills

- Breaking Machine Operation

- Machine Maintenance

- Tooling Knowledge

- Material Handling

- Safety Compliance

- Quality Control

Work Experience

Breaking Machine Operator

- Adhered to safety protocols and followed all necessary precautions to minimize risks.

- Collaborated with team members to ensure smooth operation and efficient production flow.

- Utilized knowledge of machine specifications to determine optimal settings for different materials and sizes.

- Maintained a clean and organized work area, minimizing hazards and promoting efficiency.

Breaking Machine Operator

- Operated breaking machines to break down large chunks of material into smaller pieces, ensuring adherence to specified size requirements.

- Monitored and adjusted machine settings to optimize production and minimize waste.

- Loaded and unloaded materials, ensuring proper positioning for efficient breaking.

- Identified and resolved malfunctions promptly, maintaining machine uptime and productivity.

Accomplishments

- Successfully implemented a new process for tool maintenance, reducing downtime by 15% and improving machine efficiency.

- Trained and mentored a junior operator, fostering their skills and ensuring seamless production transitions.

- Collaborated with engineers to optimize machine settings, resulting in a 10% increase in production output.

- Effectively diagnosed and resolved complex machine malfunctions, reducing repair time by 20%.

- Consistently maintained high levels of machine cleanliness and orderliness, ensuring optimal performance and safety.

Awards

- Achieved Employee of the Month recognition for consistently exceeding performance targets in machine precision and throughput.

- Recognized for Exceptional Safety Performance due to consistent adherence to safety protocols and proactive hazard identification.

- Received the Production Excellence Award for achieving recordbreaking machine utilization rates.

- Honored for Innovation in Production for developing a new technique to increase machine accuracy by 5%.

Certificates

- OSHA 10Hour Safety Certification

- ANSI B11.19 Safety Certification

- CNC Programming Certification

- Precision Measurement Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Breaking Machine Operator

- Highlight your expertise in breaking machine operation and maintenance, including technical knowledge and troubleshooting skills.

- Quantify your achievements with specific metrics, such as increased production efficiency or reduced downtime.

- Showcase your commitment to safety by emphasizing your adherence to safety protocols and training.

- Tailor your resume to the specific job description, highlighting the skills and experience that most closely align with the requirements.

Essential Experience Highlights for a Strong Breaking Machine Operator Resume

- Operate and manage breaking machines to break down scrap materials into smaller pieces.

- Perform routine maintenance and troubleshooting on breaking machines to ensure optimal performance.

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

- Unload and load materials using forklifts or other material handling equipment.

- Inspect materials and components for defects or damage before and after processing.

- Monitor production processes and make adjustments as needed to optimize efficiency and quality.

- Collaborate with other team members to ensure smooth production flow and resolve any operational issues.

Frequently Asked Questions (FAQ’s) For Breaking Machine Operator

What is the primary role of a Breaking Machine Operator?

The primary role of a Breaking Machine Operator is to operate and maintain breaking machines used to break down scrap materials or components into smaller pieces.

What are the key skills required for this position?

The key skills required for a Breaking Machine Operator include operating and maintaining breaking machines, material handling, safety compliance, quality control, and tooling knowledge.

What industries commonly employ Breaking Machine Operators?

Breaking Machine Operators are commonly employed in the manufacturing, recycling, and construction industries.

What are the career advancement opportunities for this role?

Breaking Machine Operators with experience and additional training may advance to roles such as Production Supervisor, Maintenance Technician, or Quality Control Inspector.

Is certification required to become a Breaking Machine Operator?

While certification is not typically required, obtaining industry-recognized certifications can enhance your credibility and job prospects.

What are the safety precautions that Breaking Machine Operators must adhere to?

Breaking Machine Operators must follow strict safety protocols, including wearing appropriate personal protective equipment (PPE), being aware of potential hazards, and receiving proper training on the safe operation of machinery.