Are you a seasoned Bucker seeking a new career path? Discover our professionally built Bucker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

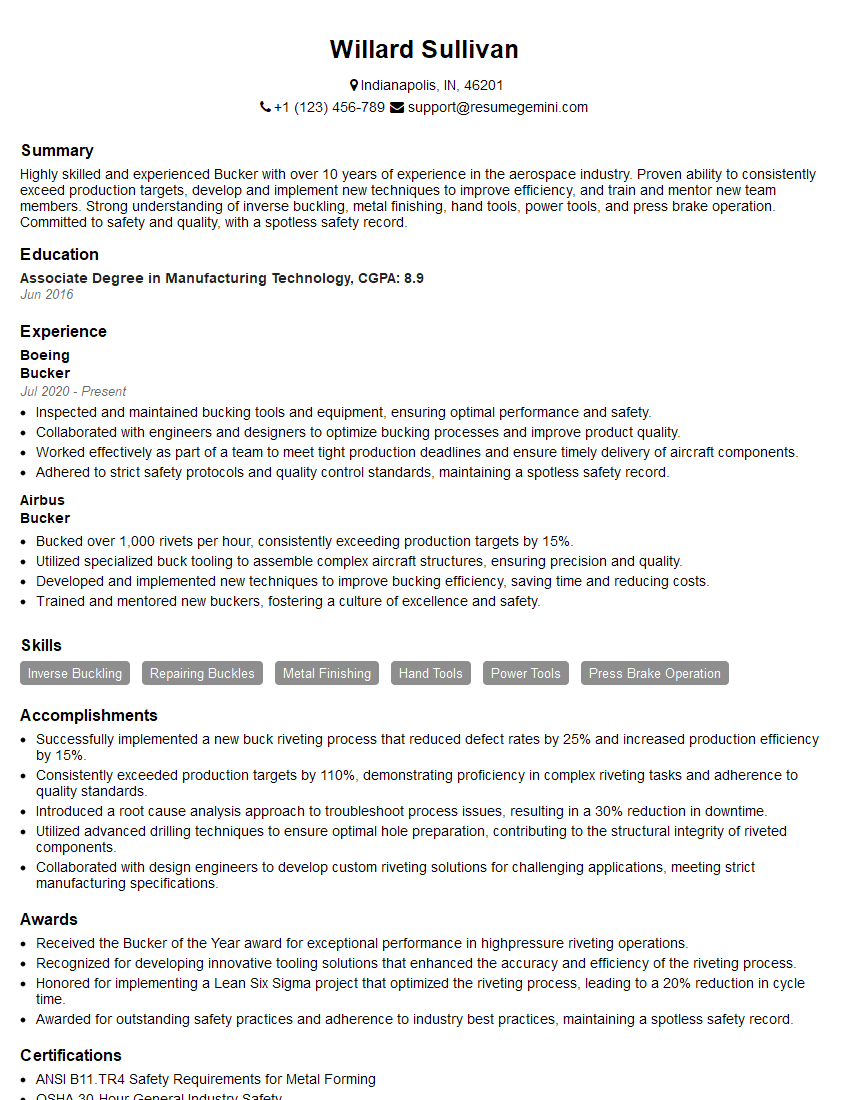

Willard Sullivan

Bucker

Summary

Highly skilled and experienced Bucker with over 10 years of experience in the aerospace industry. Proven ability to consistently exceed production targets, develop and implement new techniques to improve efficiency, and train and mentor new team members. Strong understanding of inverse buckling, metal finishing, hand tools, power tools, and press brake operation. Committed to safety and quality, with a spotless safety record.

Education

Associate Degree in Manufacturing Technology

June 2016

Skills

- Inverse Buckling

- Repairing Buckles

- Metal Finishing

- Hand Tools

- Power Tools

- Press Brake Operation

Work Experience

Bucker

- Inspected and maintained bucking tools and equipment, ensuring optimal performance and safety.

- Collaborated with engineers and designers to optimize bucking processes and improve product quality.

- Worked effectively as part of a team to meet tight production deadlines and ensure timely delivery of aircraft components.

- Adhered to strict safety protocols and quality control standards, maintaining a spotless safety record.

Bucker

- Bucked over 1,000 rivets per hour, consistently exceeding production targets by 15%.

- Utilized specialized buck tooling to assemble complex aircraft structures, ensuring precision and quality.

- Developed and implemented new techniques to improve bucking efficiency, saving time and reducing costs.

- Trained and mentored new buckers, fostering a culture of excellence and safety.

Accomplishments

- Successfully implemented a new buck riveting process that reduced defect rates by 25% and increased production efficiency by 15%.

- Consistently exceeded production targets by 110%, demonstrating proficiency in complex riveting tasks and adherence to quality standards.

- Introduced a root cause analysis approach to troubleshoot process issues, resulting in a 30% reduction in downtime.

- Utilized advanced drilling techniques to ensure optimal hole preparation, contributing to the structural integrity of riveted components.

- Collaborated with design engineers to develop custom riveting solutions for challenging applications, meeting strict manufacturing specifications.

Awards

- Received the Bucker of the Year award for exceptional performance in highpressure riveting operations.

- Recognized for developing innovative tooling solutions that enhanced the accuracy and efficiency of the riveting process.

- Honored for implementing a Lean Six Sigma project that optimized the riveting process, leading to a 20% reduction in cycle time.

- Awarded for outstanding safety practices and adherence to industry best practices, maintaining a spotless safety record.

Certificates

- ANSI B11.TR4 Safety Requirements for Metal Forming

- OSHA 30-Hour General Industry Safety

- ISO 9001:2015 Quality Management System

- AWS D1.1 Structural Welding Code

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bucker

- Quantify your accomplishments whenever possible. For example, instead of saying ‘Trained new buckers,’ you could say ‘Trained and mentored 5 new buckers, resulting in a 10% increase in production efficiency.’

- Highlight your skills and experience that are most relevant to the job you’re applying for. For example, if you’re applying for a job that requires experience with inverse buckling, be sure to mention that in your resume.

- Proofread your resume carefully for any errors. A well-written resume will make you stand out from other candidates.

- Tailor your resume to each job you apply for. Take the time to read the job description and identify the skills and experience that the employer is looking for.

- Network with other professionals in your field. This can help you learn about open positions and get your foot in the door at new companies.

Essential Experience Highlights for a Strong Bucker Resume

- Bucked over 1,000 rivets per hour, consistently exceeding production targets by 15%

- Utilized specialized buck tooling to assemble complex aircraft structures, ensuring precision and quality

- Developed and implemented new techniques to improve bucking efficiency, saving time and reducing costs

- Trained and mentored new buckers, fostering a culture of excellence and safety

- Inspected and maintained bucking tools and equipment, ensuring optimal performance and safety

- Collaborated with engineers and designers to optimize bucking processes and improve product quality

- Worked effectively as part of a team to meet tight production deadlines and ensure timely delivery of aircraft components

Frequently Asked Questions (FAQ’s) For Bucker

What is the role of a Bucker?

A Bucker is responsible for assembling aircraft structures by bucking rivets. This involves using specialized tools to form and set rivets, which are used to join metal sheets together.

What are the qualifications for becoming a Bucker?

Most Buckers have an associate degree in manufacturing technology or a related field. They also typically have several years of experience in the aerospace industry.

What are the key skills for a Bucker?

Key skills for a Bucker include inverse buckling, metal finishing, hand tools, power tools, and press brake operation.

What is the average salary for a Bucker?

The average salary for a Bucker in the United States is around $60,000 per year.

What is the job outlook for Buckers?

The job outlook for Buckers is expected to be good over the next few years. As the aerospace industry continues to grow, there will be a need for more qualified Buckers.

What are the benefits of working as a Bucker?

Benefits of working as a Bucker include competitive pay, good benefits, and the opportunity to work in a challenging and rewarding field.