Are you a seasoned Bulk Plant Manager seeking a new career path? Discover our professionally built Bulk Plant Manager Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

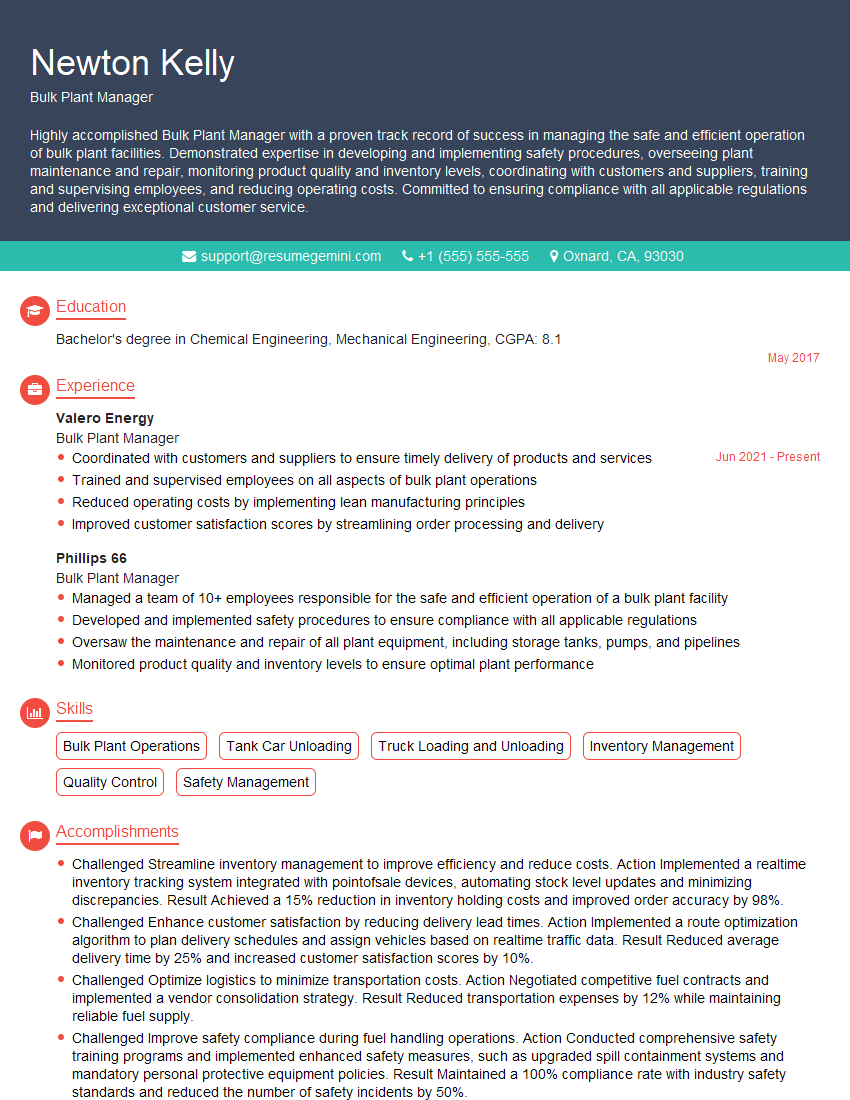

Newton Kelly

Bulk Plant Manager

Summary

Highly accomplished Bulk Plant Manager with a proven track record of success in managing the safe and efficient operation of bulk plant facilities. Demonstrated expertise in developing and implementing safety procedures, overseeing plant maintenance and repair, monitoring product quality and inventory levels, coordinating with customers and suppliers, training and supervising employees, and reducing operating costs. Committed to ensuring compliance with all applicable regulations and delivering exceptional customer service.

Education

Bachelor’s degree in Chemical Engineering, Mechanical Engineering

May 2017

Skills

- Bulk Plant Operations

- Tank Car Unloading

- Truck Loading and Unloading

- Inventory Management

- Quality Control

- Safety Management

Work Experience

Bulk Plant Manager

- Coordinated with customers and suppliers to ensure timely delivery of products and services

- Trained and supervised employees on all aspects of bulk plant operations

- Reduced operating costs by implementing lean manufacturing principles

- Improved customer satisfaction scores by streamlining order processing and delivery

Bulk Plant Manager

- Managed a team of 10+ employees responsible for the safe and efficient operation of a bulk plant facility

- Developed and implemented safety procedures to ensure compliance with all applicable regulations

- Oversaw the maintenance and repair of all plant equipment, including storage tanks, pumps, and pipelines

- Monitored product quality and inventory levels to ensure optimal plant performance

Accomplishments

- Challenged Streamline inventory management to improve efficiency and reduce costs. Action Implemented a realtime inventory tracking system integrated with pointofsale devices, automating stock level updates and minimizing discrepancies. Result Achieved a 15% reduction in inventory holding costs and improved order accuracy by 98%.

- Challenged Enhance customer satisfaction by reducing delivery lead times. Action Implemented a route optimization algorithm to plan delivery schedules and assign vehicles based on realtime traffic data. Result Reduced average delivery time by 25% and increased customer satisfaction scores by 10%.

- Challenged Optimize logistics to minimize transportation costs. Action Negotiated competitive fuel contracts and implemented a vendor consolidation strategy. Result Reduced transportation expenses by 12% while maintaining reliable fuel supply.

- Challenged Improve safety compliance during fuel handling operations. Action Conducted comprehensive safety training programs and implemented enhanced safety measures, such as upgraded spill containment systems and mandatory personal protective equipment policies. Result Maintained a 100% compliance rate with industry safety standards and reduced the number of safety incidents by 50%.

- Challenged Maximize plant efficiency by optimizing equipment performance. Action Implemented a predictive maintenance program using IoT sensors to monitor equipment health and schedule maintenance proactively. Result Extended equipment lifespan by 15% and minimized unplanned downtime, leading to increased production capacity.

Awards

- Recipient of the National Safety Award for exceptional performance in maintaining a safe and compliant bulk plant operation, resulting in zero recordable injuries for three consecutive years.

- Honored with the Bulk Plant Manager of the Year award from the industry association, recognizing outstanding leadership and innovation in managing a highvolume bulk plant.

- Awarded the Environmental Stewardship Award for implementing sustainable practices that significantly reduced the plants carbon footprint and waste generation.

Certificates

- Certified Bulk Plant Operator (CBPO)

- Certified Petroleum Inspector (CPI)

- Petroleum Equipment Institute (PEI) Certification

- National Institute for Storage Tank Management (NISTM) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bulk Plant Manager

- Highlight your experience and expertise in bulk plant operations, including tank car unloading, truck loading and unloading, inventory management, quality control, and safety management.

- Quantify your accomplishments whenever possible, providing specific examples of how you have improved plant performance, reduced costs, or enhanced customer satisfaction.

- Showcase your leadership and management skills by describing your experience in training, supervising, and motivating a team of employees.

- Emphasize your commitment to safety and compliance by highlighting your role in developing and implementing safety procedures and ensuring adherence to all applicable regulations.

Essential Experience Highlights for a Strong Bulk Plant Manager Resume

- Managed a team of 10+ employees responsible for the safe and efficient operation of a bulk plant facility.

- Developed and implemented safety procedures to ensure compliance with all applicable regulations.

- Oversaw the maintenance and repair of all plant equipment, including storage tanks, pumps, and pipelines.

- Monitored product quality and inventory levels to ensure optimal plant performance.

- Coordinated with customers and suppliers to ensure timely delivery of products and services.

- Trained and supervised employees on all aspects of bulk plant operations.

- Reduced operating costs by implementing lean manufacturing principles.

- Improved customer satisfaction scores by streamlining order processing and delivery.

Frequently Asked Questions (FAQ’s) For Bulk Plant Manager

What is the primary role of a Bulk Plant Manager?

The primary role of a Bulk Plant Manager is to oversee the safe and efficient operation of a bulk plant facility, ensuring compliance with all applicable regulations and delivering exceptional customer service.

What are the key responsibilities of a Bulk Plant Manager?

Key responsibilities include managing a team of employees, developing and implementing safety procedures, overseeing plant maintenance and repair, monitoring product quality and inventory levels, coordinating with customers and suppliers, training and supervising employees, and reducing operating costs.

What qualifications are required to become a Bulk Plant Manager?

Typically, a Bachelor’s degree in Chemical Engineering, Mechanical Engineering, or a related field is required.

What are the top companies that hire Bulk Plant Managers?

Top companies that hire Bulk Plant Managers include Phillips 66 and Valero Energy.

What are the salary expectations for Bulk Plant Managers?

Salary expectations can vary depending on experience, qualifications, and location, but generally range from $60,000 to $100,000 annually.

What career opportunities are available for Bulk Plant Managers?

Bulk Plant Managers with experience and expertise can advance to roles such as Operations Manager, Plant Manager, or General Manager.

What are the challenges faced by Bulk Plant Managers?

Challenges faced by Bulk Plant Managers include ensuring the safety and compliance of the plant, managing inventory levels and product quality, and meeting customer demands while maintaining cost-effectiveness.