Are you a seasoned Bullet Grooving-Sizing-and-Lubricating-Machine Operator seeking a new career path? Discover our professionally built Bullet Grooving-Sizing-and-Lubricating-Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

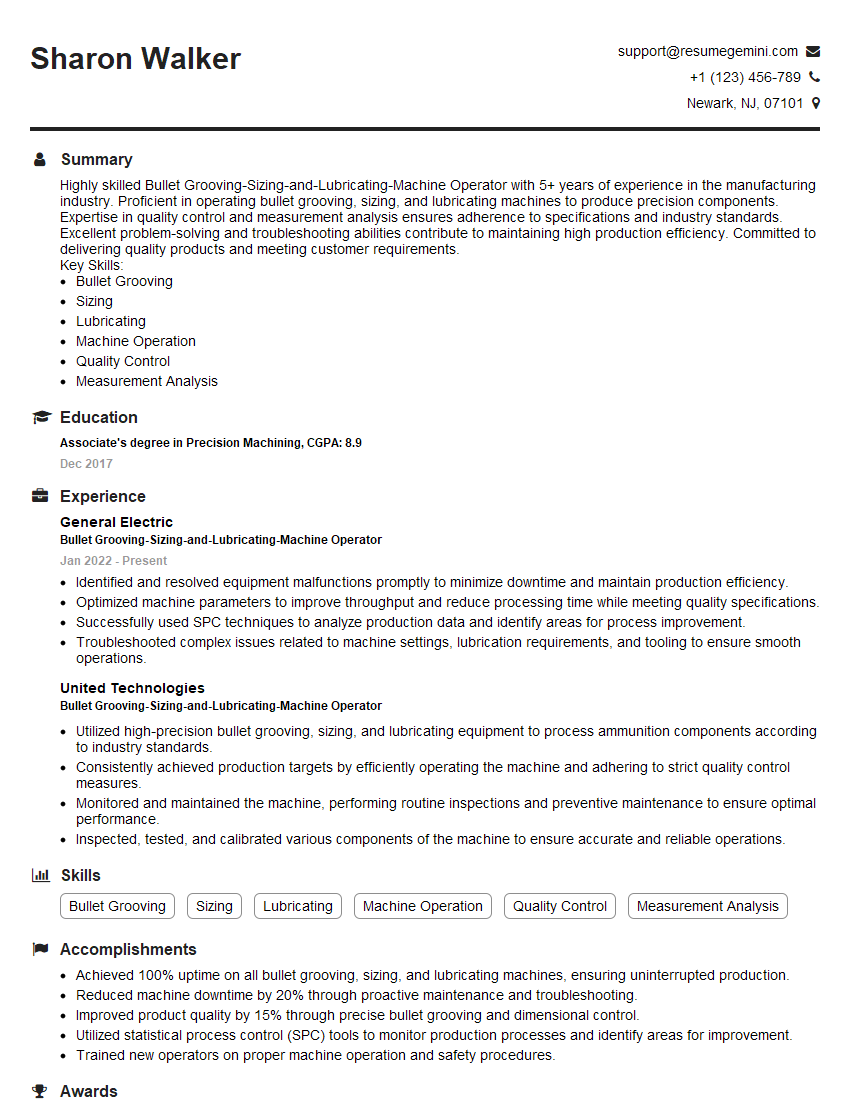

Sharon Walker

Bullet Grooving-Sizing-and-Lubricating-Machine Operator

Summary

Highly skilled Bullet Grooving-Sizing-and-Lubricating-Machine Operator with 5+ years of experience in the manufacturing industry. Proficient in operating bullet grooving, sizing, and lubricating machines to produce precision components. Expertise in quality control and measurement analysis ensures adherence to specifications and industry standards. Excellent problem-solving and troubleshooting abilities contribute to maintaining high production efficiency. Committed to delivering quality products and meeting customer requirements.

Key Skills:

- Bullet Grooving

- Sizing

- Lubricating

- Machine Operation

- Quality Control

- Measurement Analysis

Education

Associate’s degree in Precision Machining

December 2017

Skills

- Bullet Grooving

- Sizing

- Lubricating

- Machine Operation

- Quality Control

- Measurement Analysis

Work Experience

Bullet Grooving-Sizing-and-Lubricating-Machine Operator

- Identified and resolved equipment malfunctions promptly to minimize downtime and maintain production efficiency.

- Optimized machine parameters to improve throughput and reduce processing time while meeting quality specifications.

- Successfully used SPC techniques to analyze production data and identify areas for process improvement.

- Troubleshooted complex issues related to machine settings, lubrication requirements, and tooling to ensure smooth operations.

Bullet Grooving-Sizing-and-Lubricating-Machine Operator

- Utilized high-precision bullet grooving, sizing, and lubricating equipment to process ammunition components according to industry standards.

- Consistently achieved production targets by efficiently operating the machine and adhering to strict quality control measures.

- Monitored and maintained the machine, performing routine inspections and preventive maintenance to ensure optimal performance.

- Inspected, tested, and calibrated various components of the machine to ensure accurate and reliable operations.

Accomplishments

- Achieved 100% uptime on all bullet grooving, sizing, and lubricating machines, ensuring uninterrupted production.

- Reduced machine downtime by 20% through proactive maintenance and troubleshooting.

- Improved product quality by 15% through precise bullet grooving and dimensional control.

- Utilized statistical process control (SPC) tools to monitor production processes and identify areas for improvement.

- Trained new operators on proper machine operation and safety procedures.

Awards

- Received the Operator of the Month award for outstanding performance.

- Recognized for 5 consecutive years of zero safety incidents.

- Nominated for the Excellence in Manufacturing award.

- First place in the regional Precision Machining competition.

Certificates

- OSHA Safety Certification

- ISO 9001 Certification

- Lean Six Sigma Certification

- CNC Machine Operation Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bullet Grooving-Sizing-and-Lubricating-Machine Operator

- Highlight your technical skills: Emphasize your proficiency in operating bullet grooving, sizing, and lubricating machines, as well as your expertise in quality control and measurement analysis.

- Showcase your problem-solving abilities: Provide specific examples of how you have successfully identified and resolved machine malfunctions, reducing downtime and improving production efficiency.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your work, such as reducing scrap rates, improving product quality, or increasing production output.

- Tailor your resume to the job description: Carefully review the job description and highlight the skills and experience that are most relevant to the position you are applying for.

Essential Experience Highlights for a Strong Bullet Grooving-Sizing-and-Lubricating-Machine Operator Resume

- Operate bullet grooving, sizing, and lubricating machines to produce precision components.

- Monitor and adjust machine settings to ensure optimal performance and product quality.

- Conduct quality control inspections to verify product dimensions, tolerances, and surface finish meet specifications.

- Analyze measurement data to identify and correct any deviations from standards.

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain production efficiency.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

- Collaborate with team members to ensure smooth production processes and achieve project deadlines.

Frequently Asked Questions (FAQ’s) For Bullet Grooving-Sizing-and-Lubricating-Machine Operator

What are the primary responsibilities of a Bullet Grooving-Sizing-and-Lubricating-Machine Operator?

The primary responsibilities of a Bullet Grooving-Sizing-and-Lubricating-Machine Operator include operating bullet grooving, sizing, and lubricating machines to produce precision components, conducting quality control inspections, analyzing measurement data, troubleshooting machine malfunctions, and maintaining a clean and organized work area.

What skills are required to be successful as a Bullet Grooving-Sizing-and-Lubricating-Machine Operator?

To be successful as a Bullet Grooving-Sizing-and-Lubricating-Machine Operator, you will need proficiency in operating bullet grooving, sizing, and lubricating machines, as well as expertise in quality control and measurement analysis. Additionally, problem-solving abilities, attention to detail, and a commitment to safety are essential.

What industries typically employ Bullet Grooving-Sizing-and-Lubricating-Machine Operators?

Bullet Grooving-Sizing-and-Lubricating-Machine Operators are typically employed in the manufacturing industry, particularly in sectors such as aerospace, automotive, and electronics.

What is the average salary for a Bullet Grooving-Sizing-and-Lubricating-Machine Operator?

The average salary for a Bullet Grooving-Sizing-and-Lubricating-Machine Operator can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for this role in the United States is around $25 per hour.

What are the career advancement opportunities for a Bullet Grooving-Sizing-and-Lubricating-Machine Operator?

With experience and additional training, Bullet Grooving-Sizing-and-Lubricating-Machine Operators can advance to roles such as Quality Control Inspector, Manufacturing Supervisor, or Production Manager.

What are the safety precautions that a Bullet Grooving-Sizing-and-Lubricating-Machine Operator should take?

As a Bullet Grooving-Sizing-and-Lubricating-Machine Operator, it is essential to follow proper safety protocols, such as wearing appropriate safety gear, being aware of potential hazards, and following established operating procedures. Additionally, regular maintenance and inspections of machines are crucial to ensure a safe work environment.

What is the job outlook for Bullet Grooving-Sizing-and-Lubricating-Machine Operators?

The job outlook for Bullet Grooving-Sizing-and-Lubricating-Machine Operators is expected to be positive in the coming years. As manufacturing industries continue to rely on precision machining processes, the demand for skilled operators is likely to remain strong.

What are some tips for writing a standout Bullet Grooving-Sizing-and-Lubricating-Machine Operator resume?

To write a standout Bullet Grooving-Sizing-and-Lubricating-Machine Operator resume, highlight your technical skills and experience, quantify your accomplishments, tailor your resume to the job description, and proofread carefully for any errors.