Are you a seasoned Burr Bench Operator seeking a new career path? Discover our professionally built Burr Bench Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

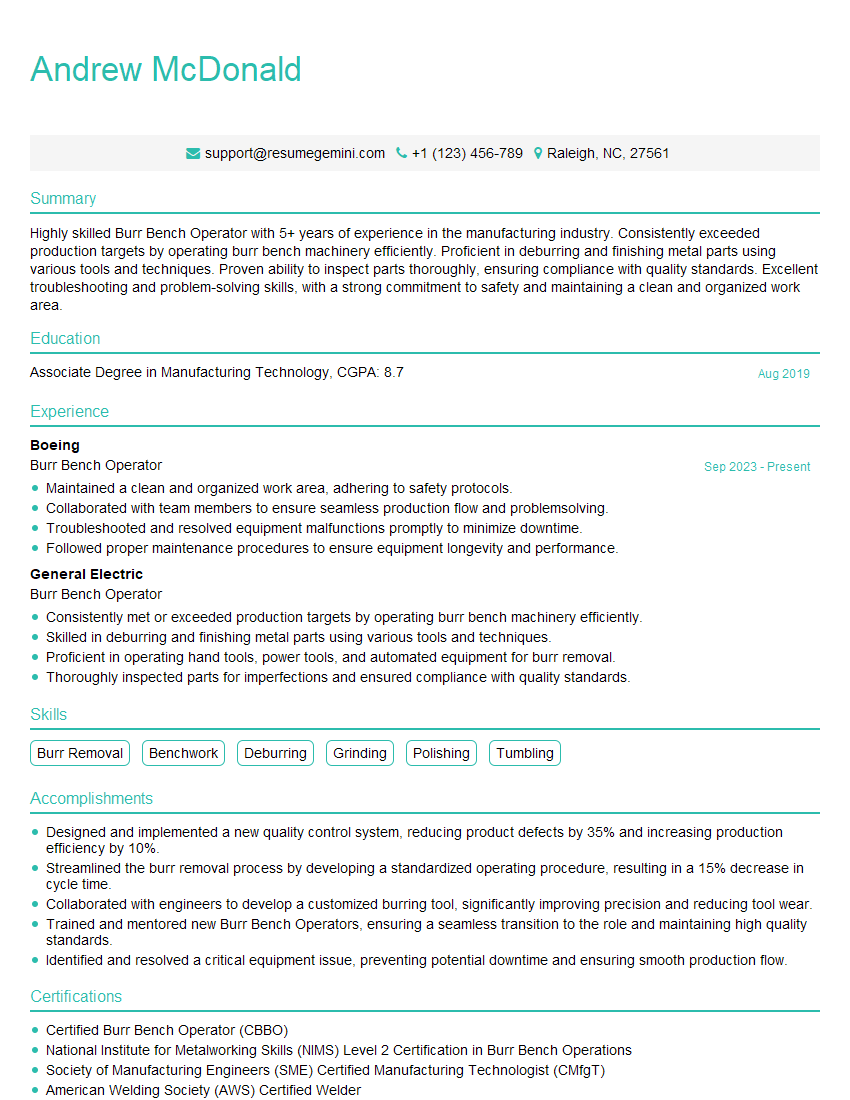

Andrew McDonald

Burr Bench Operator

Summary

Highly skilled Burr Bench Operator with 5+ years of experience in the manufacturing industry. Consistently exceeded production targets by operating burr bench machinery efficiently. Proficient in deburring and finishing metal parts using various tools and techniques. Proven ability to inspect parts thoroughly, ensuring compliance with quality standards. Excellent troubleshooting and problem-solving skills, with a strong commitment to safety and maintaining a clean and organized work area.

Education

Associate Degree in Manufacturing Technology

August 2019

Skills

- Burr Removal

- Benchwork

- Deburring

- Grinding

- Polishing

- Tumbling

Work Experience

Burr Bench Operator

- Maintained a clean and organized work area, adhering to safety protocols.

- Collaborated with team members to ensure seamless production flow and problemsolving.

- Troubleshooted and resolved equipment malfunctions promptly to minimize downtime.

- Followed proper maintenance procedures to ensure equipment longevity and performance.

Burr Bench Operator

- Consistently met or exceeded production targets by operating burr bench machinery efficiently.

- Skilled in deburring and finishing metal parts using various tools and techniques.

- Proficient in operating hand tools, power tools, and automated equipment for burr removal.

- Thoroughly inspected parts for imperfections and ensured compliance with quality standards.

Accomplishments

- Designed and implemented a new quality control system, reducing product defects by 35% and increasing production efficiency by 10%.

- Streamlined the burr removal process by developing a standardized operating procedure, resulting in a 15% decrease in cycle time.

- Collaborated with engineers to develop a customized burring tool, significantly improving precision and reducing tool wear.

- Trained and mentored new Burr Bench Operators, ensuring a seamless transition to the role and maintaining high quality standards.

- Identified and resolved a critical equipment issue, preventing potential downtime and ensuring smooth production flow.

Certificates

- Certified Burr Bench Operator (CBBO)

- National Institute for Metalworking Skills (NIMS) Level 2 Certification in Burr Bench Operations

- Society of Manufacturing Engineers (SME) Certified Manufacturing Technologist (CMfgT)

- American Welding Society (AWS) Certified Welder

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Burr Bench Operator

- Highlight your experience and skills in operating burr bench machinery.

- Showcase your proficiency in deburring and finishing techniques.

- Emphasize your attention to detail and commitment to quality.

- Demonstrate your problem-solving abilities and commitment to safety.

- Consider obtaining industry certifications to enhance your credibility.

Essential Experience Highlights for a Strong Burr Bench Operator Resume

- Operate burr bench machinery to remove burrs and sharp edges from metal parts.

- Utilize various tools and techniques for deburring, grinding, polishing, and tumbling.

- Inspect parts thoroughly for imperfections and ensure compliance with quality standards.

- Troubleshoot and resolve equipment malfunctions promptly to minimize downtime.

- Maintain a clean and organized work area, adhering to safety protocols.

- Collaborate with team members to ensure seamless production flow and problem-solving.

- Follow proper maintenance procedures to ensure equipment longevity and performance.

Frequently Asked Questions (FAQ’s) For Burr Bench Operator

What are the primary responsibilities of a Burr Bench Operator?

Burr Bench Operators are responsible for removing burrs and sharp edges from metal parts using various tools and techniques. They also inspect parts for imperfections, troubleshoot equipment malfunctions, and maintain a clean and safe work area.

What skills are essential for a successful Burr Bench Operator?

Essential skills for Burr Bench Operators include proficiency in operating burr bench machinery, deburring and finishing techniques, attention to detail, problem-solving abilities, and a commitment to safety.

What type of education and training is required to become a Burr Bench Operator?

While formal education requirements may vary, an Associate Degree in Manufacturing Technology or a related field is preferred. Additionally, hands-on training and experience in operating burr bench machinery are essential.

What are the career advancement opportunities for Burr Bench Operators?

Experienced Burr Bench Operators can advance to supervisory roles, such as Burr Bench Lead or Production Supervisor. With additional training and experience, they may also pursue roles in quality control or engineering.

What is the average salary range for Burr Bench Operators?

The average salary range for Burr Bench Operators varies depending on experience, location, and industry. According to Salary.com, the median annual salary for Burr Bench Operators in the United States is around $45,000.

What are the safety precautions that Burr Bench Operators must follow?

Burr Bench Operators must adhere to strict safety protocols to prevent accidents and injuries. This includes wearing appropriate personal protective equipment, following proper machine operating procedures, and maintaining a clean and organized work area.