Are you a seasoned Butadiene Compressor Operator seeking a new career path? Discover our professionally built Butadiene Compressor Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

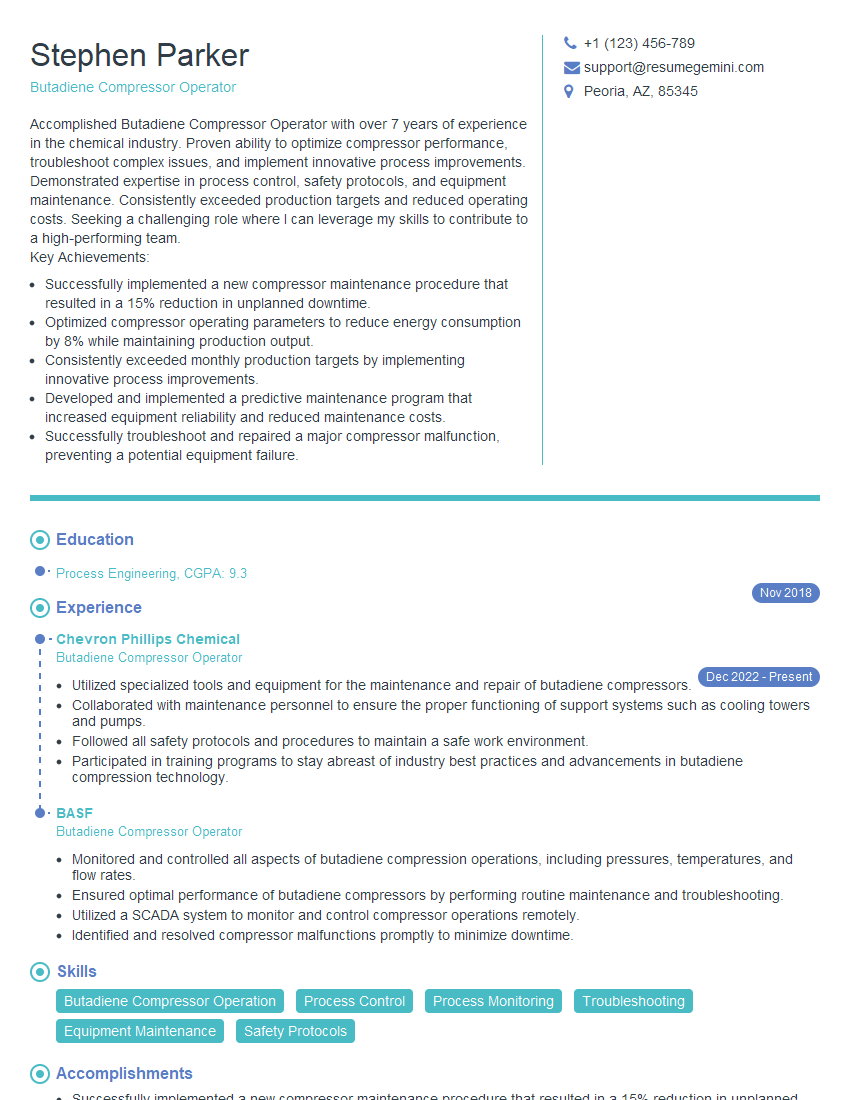

Stephen Parker

Butadiene Compressor Operator

Summary

Accomplished Butadiene Compressor Operator with over 7 years of experience in the chemical industry. Proven ability to optimize compressor performance, troubleshoot complex issues, and implement innovative process improvements. Demonstrated expertise in process control, safety protocols, and equipment maintenance. Consistently exceeded production targets and reduced operating costs. Seeking a challenging role where I can leverage my skills to contribute to a high-performing team.

Key Achievements:

- Successfully implemented a new compressor maintenance procedure that resulted in a 15% reduction in unplanned downtime.

- Optimized compressor operating parameters to reduce energy consumption by 8% while maintaining production output.

- Consistently exceeded monthly production targets by implementing innovative process improvements.

- Developed and implemented a predictive maintenance program that increased equipment reliability and reduced maintenance costs.

- Successfully troubleshoot and repaired a major compressor malfunction, preventing a potential equipment failure.

Education

Process Engineering

November 2018

Skills

- Butadiene Compressor Operation

- Process Control

- Process Monitoring

- Troubleshooting

- Equipment Maintenance

- Safety Protocols

Work Experience

Butadiene Compressor Operator

- Utilized specialized tools and equipment for the maintenance and repair of butadiene compressors.

- Collaborated with maintenance personnel to ensure the proper functioning of support systems such as cooling towers and pumps.

- Followed all safety protocols and procedures to maintain a safe work environment.

- Participated in training programs to stay abreast of industry best practices and advancements in butadiene compression technology.

Butadiene Compressor Operator

- Monitored and controlled all aspects of butadiene compression operations, including pressures, temperatures, and flow rates.

- Ensured optimal performance of butadiene compressors by performing routine maintenance and troubleshooting.

- Utilized a SCADA system to monitor and control compressor operations remotely.

- Identified and resolved compressor malfunctions promptly to minimize downtime.

Accomplishments

- Successfully implemented a new compressor maintenance procedure that resulted in a 15% reduction in unplanned downtime.

- Optimized compressor operating parameters to reduce energy consumption by 8% while maintaining production output.

- Consistently exceeded monthly production targets by implementing innovative process improvements.

- Developed and implemented a predictive maintenance program that increased equipment reliability and reduced maintenance costs.

- Successfully troubleshoot and repaired a major compressor malfunction, preventing a potential equipment failure.

Awards

- Received the Outstanding Performance Award for consistently exceeding production targets and maintaining a high level of operational efficiency.

- Recognized as Employee of the Month for developing and presenting a training program on butadiene compressor troubleshooting.

- Awarded the Safety Excellence Award for maintaining an impeccable safety record and adhering to all industry regulations.

- Recognized for leadership and teamwork in resolving a critical equipment failure that prevented a costly plant shutdown.

Certificates

- OSHA 30Hour HAZWOPER

- Butadiene Process Safety Management

- Certified Butadiene Compressor Operator

- National Institute of Chemical Engineers (NICHE) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Butadiene Compressor Operator

- Highlight your technical skills: Emphasize your proficiency in operating and maintaining butadiene compressors, including your ability to troubleshoot and resolve complex issues.

- Quantify your accomplishments: Use specific metrics and data to demonstrate your impact on the organization, such as reducing downtime, improving production efficiency, and implementing cost-saving measures.

- Showcase your safety??: Highlight your adherence to safety protocols and your commitment to maintaining a safe work environment.

- Tailor your resume to the specific job description: Carefully review the job description and tailor your resume to match the requirements and responsibilities outlined.

- Proofread carefully: Ensure that your resume is free of errors and that it is well-organized and easy to read.

Essential Experience Highlights for a Strong Butadiene Compressor Operator Resume

- Operate and monitor butadiene compressors to ensure optimal performance and production output.

- Control and adjust process variables such as temperature, pressure, and flow rate to maintain process specifications.

- Monitor and interpret process data to identify deviations and implement corrective actions.

- Troubleshoot and resolve compressor malfunctions, including mechanical, electrical, and process-related issues.

- Perform routine maintenance and repairs on compressors and associated equipment.

- Adhere to safety protocols and emergency procedures to ensure a safe work environment.

- Maintain detailed records and documentation of compressor operations and maintenance activities.

- Work effectively as part of a team and communicate clearly with other operators and supervisors.

Frequently Asked Questions (FAQ’s) For Butadiene Compressor Operator

What are the key responsibilities of a Butadiene Compressor Operator?

The key responsibilities of a Butadiene Compressor Operator include operating and monitoring butadiene compressors, controlling and adjusting process variables, monitoring and interpreting process data, troubleshooting and resolving compressor malfunctions, performing routine maintenance and repairs, adhering to safety protocols, and maintaining detailed records.

What qualifications are required to become a Butadiene Compressor Operator?

Typically, a high school diploma or equivalent is required to become a Butadiene Compressor Operator. Additional qualifications may include an associate degree or certificate in process engineering, chemistry, or a related field.

What are the career prospects for a Butadiene Compressor Operator?

With experience and additional training, Butadiene Compressor Operators can advance to positions such as Process Operator, Production Supervisor, or Maintenance Technician. They may also specialize in areas such as equipment maintenance, process optimization, or safety management.

What is the average salary for a Butadiene Compressor Operator?

The average salary for a Butadiene Compressor Operator in the United States is around $60,000 per year. However, salaries may vary depending on experience, location, and employer.

What are the safety protocols that a Butadiene Compressor Operator must follow?

Butadiene Compressor Operators must follow strict safety protocols to ensure a safe work environment. These protocols typically include wearing appropriate personal protective equipment, following lockout/tagout procedures, and adhering to established operating procedures.

What are the key skills that a Butadiene Compressor Operator should possess?

Key skills for a Butadiene Compressor Operator include strong technical skills in operating and maintaining butadiene compressors, troubleshooting and problem-solving abilities, process control and monitoring expertise, and adherence to safety protocols.

What are the challenges faced by Butadiene Compressor Operators?

Butadiene Compressor Operators may face challenges such as working in hazardous environments, dealing with high-pressure equipment, and troubleshooting complex technical issues. They must also be able to work independently and as part of a team to ensure smooth and efficient operation of the compressors.

What are the opportunities for professional development for Butadiene Compressor Operators?

Butadiene Compressor Operators can pursue opportunities for professional development through training programs, workshops, and conferences. They can also seek certifications in areas such as process safety management or equipment maintenance to enhance their skills and knowledge.