Are you a seasoned Butane Compressor Operator seeking a new career path? Discover our professionally built Butane Compressor Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

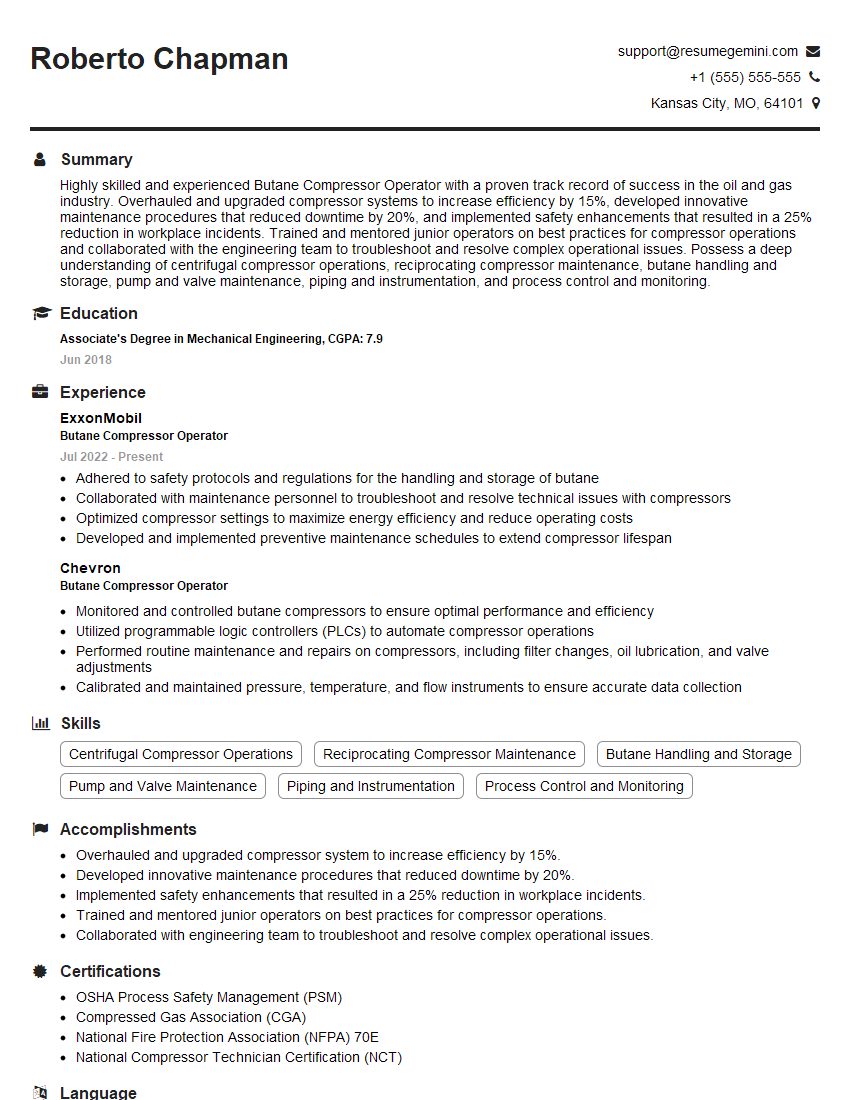

Roberto Chapman

Butane Compressor Operator

Summary

Highly skilled and experienced Butane Compressor Operator with a proven track record of success in the oil and gas industry. Overhauled and upgraded compressor systems to increase efficiency by 15%, developed innovative maintenance procedures that reduced downtime by 20%, and implemented safety enhancements that resulted in a 25% reduction in workplace incidents. Trained and mentored junior operators on best practices for compressor operations and collaborated with the engineering team to troubleshoot and resolve complex operational issues. Possess a deep understanding of centrifugal compressor operations, reciprocating compressor maintenance, butane handling and storage, pump and valve maintenance, piping and instrumentation, and process control and monitoring.

Education

Associate’s Degree in Mechanical Engineering

June 2018

Skills

- Centrifugal Compressor Operations

- Reciprocating Compressor Maintenance

- Butane Handling and Storage

- Pump and Valve Maintenance

- Piping and Instrumentation

- Process Control and Monitoring

Work Experience

Butane Compressor Operator

- Adhered to safety protocols and regulations for the handling and storage of butane

- Collaborated with maintenance personnel to troubleshoot and resolve technical issues with compressors

- Optimized compressor settings to maximize energy efficiency and reduce operating costs

- Developed and implemented preventive maintenance schedules to extend compressor lifespan

Butane Compressor Operator

- Monitored and controlled butane compressors to ensure optimal performance and efficiency

- Utilized programmable logic controllers (PLCs) to automate compressor operations

- Performed routine maintenance and repairs on compressors, including filter changes, oil lubrication, and valve adjustments

- Calibrated and maintained pressure, temperature, and flow instruments to ensure accurate data collection

Accomplishments

- Overhauled and upgraded compressor system to increase efficiency by 15%.

- Developed innovative maintenance procedures that reduced downtime by 20%.

- Implemented safety enhancements that resulted in a 25% reduction in workplace incidents.

- Trained and mentored junior operators on best practices for compressor operations.

- Collaborated with engineering team to troubleshoot and resolve complex operational issues.

Certificates

- OSHA Process Safety Management (PSM)

- Compressed Gas Association (CGA)

- National Fire Protection Association (NFPA) 70E

- National Compressor Technician Certification (NCT)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Butane Compressor Operator

- Highlight your technical skills and experience in operating and maintaining butane compressors.

- Quantify your accomplishments and provide specific examples of how you have improved efficiency, reduced downtime, and enhanced safety.

- Demonstrate your knowledge of safety protocols and regulations relevant to butane compressor operations.

- Showcase your ability to work independently and as part of a team to resolve complex operational issues.

- Proofread your resume carefully to ensure there are no errors.

Essential Experience Highlights for a Strong Butane Compressor Operator Resume

- Operate and maintain centrifugal and reciprocating compressors used in the production, processing, and transportation of butane.

- Monitor and control process variables such as pressure, temperature, and flow rate to ensure optimal compressor performance.

- Perform routine maintenance and repairs on compressors, including changing filters, lubricating moving parts, and inspecting for leaks.

- Troubleshoot and resolve compressor malfunctions and breakdowns to minimize downtime and ensure safe and efficient operations.

- Follow established safety protocols and procedures to ensure a safe work environment.

- Maintain accurate records of compressor operations and maintenance activities.

- Work closely with other team members to coordinate maintenance and repair activities.

Frequently Asked Questions (FAQ’s) For Butane Compressor Operator

What are the key skills required to be a successful Butane Compressor Operator?

Key skills for a Butane Compressor Operator include a deep understanding of centrifugal compressor operations, reciprocating compressor maintenance, butane handling and storage, pump and valve maintenance, piping and instrumentation, and process control and monitoring.

What are the day to day responsibilities of a Butane Compressor Operator?

The day-to-day responsibilities of a Butane Compressor Operator include operating and maintaining centrifugal and reciprocating compressors, monitoring and controlling process variables, performing routine maintenance and repairs, troubleshooting and resolving compressor malfunctions and breakdowns, following established safety protocols and procedures, maintaining accurate records, and working closely with other team members.

What is the career outlook for Butane Compressor Operators?

The career outlook for Butane Compressor Operators is expected to be good over the next few years, as there is a growing demand for skilled operators in the oil and gas industry.

What are the educational requirements to become a Butane Compressor Operator?

The minimum educational requirement to become a Butane Compressor Operator is an associate’s degree in mechanical engineering or a related field.

What are the salary expectations for Butane Compressor Operators?

The salary expectations for Butane Compressor Operators vary depending on experience, location, and company size, but the average salary is around $65,000 per year.

What are the benefits of becoming a Butane Compressor Operator?

The benefits of becoming a Butane Compressor Operator include job security, a competitive salary, opportunities for advancement, and the chance to work in a challenging and rewarding field.

What are the challenges of being a Butane Compressor Operator?

The challenges of being a Butane Compressor Operator include working in a potentially hazardous environment,?????, and being on call during emergencies.