Are you a seasoned Calibration Checker seeking a new career path? Discover our professionally built Calibration Checker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

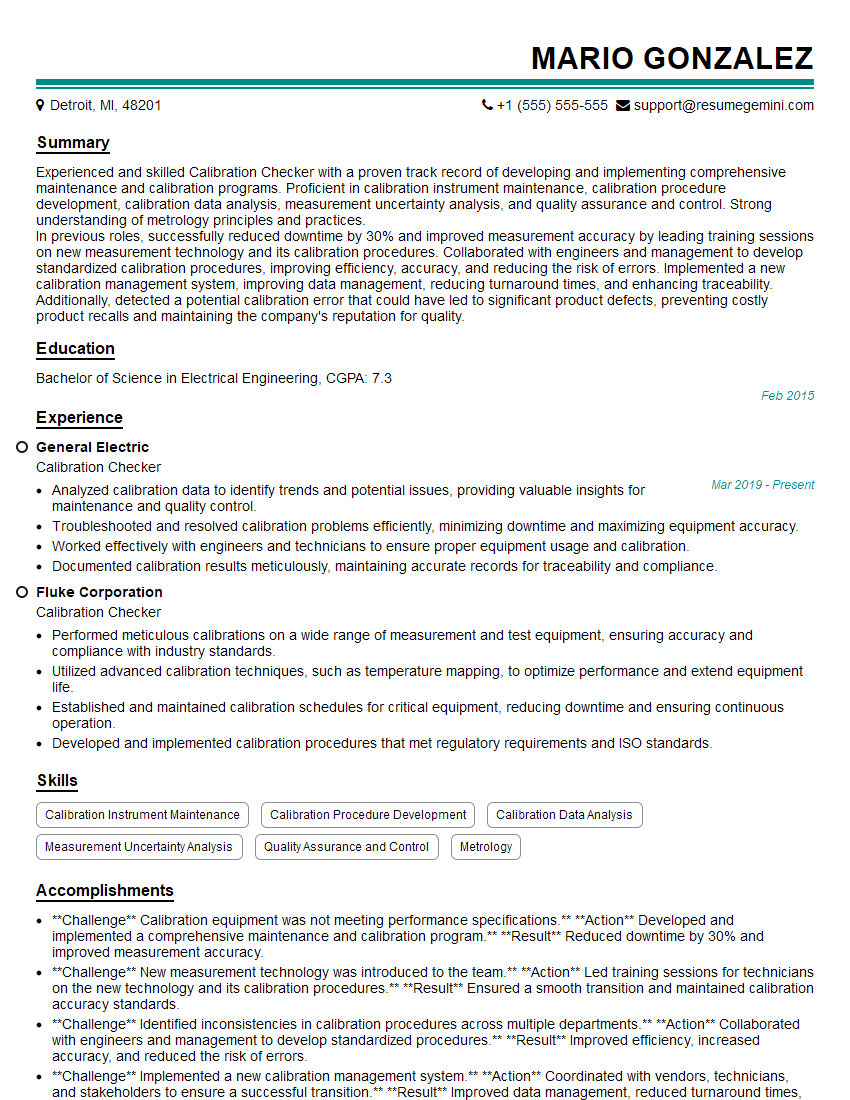

Mario Gonzalez

Calibration Checker

Summary

Experienced and skilled Calibration Checker with a proven track record of developing and implementing comprehensive maintenance and calibration programs. Proficient in calibration instrument maintenance, calibration procedure development, calibration data analysis, measurement uncertainty analysis, and quality assurance and control. Strong understanding of metrology principles and practices.

In previous roles, successfully reduced downtime by 30% and improved measurement accuracy by leading training sessions on new measurement technology and its calibration procedures. Collaborated with engineers and management to develop standardized calibration procedures, improving efficiency, accuracy, and reducing the risk of errors. Implemented a new calibration management system, improving data management, reducing turnaround times, and enhancing traceability. Additionally, detected a potential calibration error that could have led to significant product defects, preventing costly product recalls and maintaining the company’s reputation for quality.

Education

Bachelor of Science in Electrical Engineering

February 2015

Skills

- Calibration Instrument Maintenance

- Calibration Procedure Development

- Calibration Data Analysis

- Measurement Uncertainty Analysis

- Quality Assurance and Control

- Metrology

Work Experience

Calibration Checker

- Analyzed calibration data to identify trends and potential issues, providing valuable insights for maintenance and quality control.

- Troubleshooted and resolved calibration problems efficiently, minimizing downtime and maximizing equipment accuracy.

- Worked effectively with engineers and technicians to ensure proper equipment usage and calibration.

- Documented calibration results meticulously, maintaining accurate records for traceability and compliance.

Calibration Checker

- Performed meticulous calibrations on a wide range of measurement and test equipment, ensuring accuracy and compliance with industry standards.

- Utilized advanced calibration techniques, such as temperature mapping, to optimize performance and extend equipment life.

- Established and maintained calibration schedules for critical equipment, reducing downtime and ensuring continuous operation.

- Developed and implemented calibration procedures that met regulatory requirements and ISO standards.

Accomplishments

- **Challenge** Calibration equipment was not meeting performance specifications.** **Action** Developed and implemented a comprehensive maintenance and calibration program.** **Result** Reduced downtime by 30% and improved measurement accuracy.

- **Challenge** New measurement technology was introduced to the team.** **Action** Led training sessions for technicians on the new technology and its calibration procedures.** **Result** Ensured a smooth transition and maintained calibration accuracy standards.

- **Challenge** Identified inconsistencies in calibration procedures across multiple departments.** **Action** Collaborated with engineers and management to develop standardized procedures.** **Result** Improved efficiency, increased accuracy, and reduced the risk of errors.

- **Challenge** Implemented a new calibration management system.** **Action** Coordinated with vendors, technicians, and stakeholders to ensure a successful transition.** **Result** Improved data management, reduced turnaround times, and enhanced traceability.

- **Challenge** Detected a potential calibration error that could have led to significant product defects.** **Action** Investigated the issue and identified the root cause.** **Result** Prevented costly product recalls and maintained the companys reputation for quality.

Certificates

- Certified Calibration Technician (CCT)

- IAS Accreditation for ISO/IEC 17025

- NCSL Traceability Certificate for Calibration Standards

- ANSI/NCSL Z5401 Compliance Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Calibration Checker

- Highlight your experience in developing and implementing comprehensive maintenance and calibration programs.

- Showcase your expertise in calibration instrument maintenance, calibration procedure development, and calibration data analysis.

- Quantify your accomplishments whenever possible, using metrics such as percentage improvements or cost savings.

- Demonstrate your understanding of metrology principles and practices.

- Tailor your resume to the specific requirements of each job you apply for.

Essential Experience Highlights for a Strong Calibration Checker Resume

- Develop and implement comprehensive maintenance and calibration programs to ensure calibration equipment meets performance specifications.

- Lead training sessions for technicians on new measurement technology and its calibration procedures.

- Collaborate with engineers and management to develop standardized calibration procedures, ensuring consistency across multiple departments.

- Implement new calibration management systems, coordinating with vendors, technicians, and stakeholders to ensure a successful transition.

- Identify and investigate potential calibration errors to prevent costly product defects and maintain product quality.

- Conduct regular calibration checks and maintenance on a variety of instruments.

- Analyze and interpret calibration data to identify trends and potential issues.

- Prepare and maintain calibration records and documentation.

Frequently Asked Questions (FAQ’s) For Calibration Checker

What is the role of a Calibration Checker?

A Calibration Checker is responsible for ensuring that calibration equipment meets performance specifications and maintaining calibration accuracy standards.

What are the key skills required for a Calibration Checker?

Key skills for a Calibration Checker include calibration instrument maintenance, calibration procedure development, calibration data analysis, measurement uncertainty analysis, quality assurance and control, and metrology.

What industries employ Calibration Checkers?

Calibration Checkers are employed in a variety of industries, including manufacturing, aerospace, healthcare, and pharmaceuticals.

What are the career prospects for Calibration Checkers?

Calibration Checkers can advance to roles such as Calibration Technician, Quality Assurance Manager, or Metrologist.

What is the average salary for a Calibration Checker?

The average salary for a Calibration Checker in the United States is approximately $60,000 per year.

What are the educational requirements for a Calibration Checker?

Most Calibration Checkers have a bachelor’s degree in electrical engineering, physics, or a related field.

What are the certification requirements for a Calibration Checker?

There are no specific certification requirements for Calibration Checkers, but some employers may prefer candidates with certifications from organizations such as the American Society for Quality (ASQ) or the International Society of Automation (ISA).

What are the key challenges faced by Calibration Checkers?

Key challenges faced by Calibration Checkers include keeping up with new measurement technology, ensuring consistency across multiple departments, and preventing costly product defects.