Are you a seasoned Carbide Operator seeking a new career path? Discover our professionally built Carbide Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

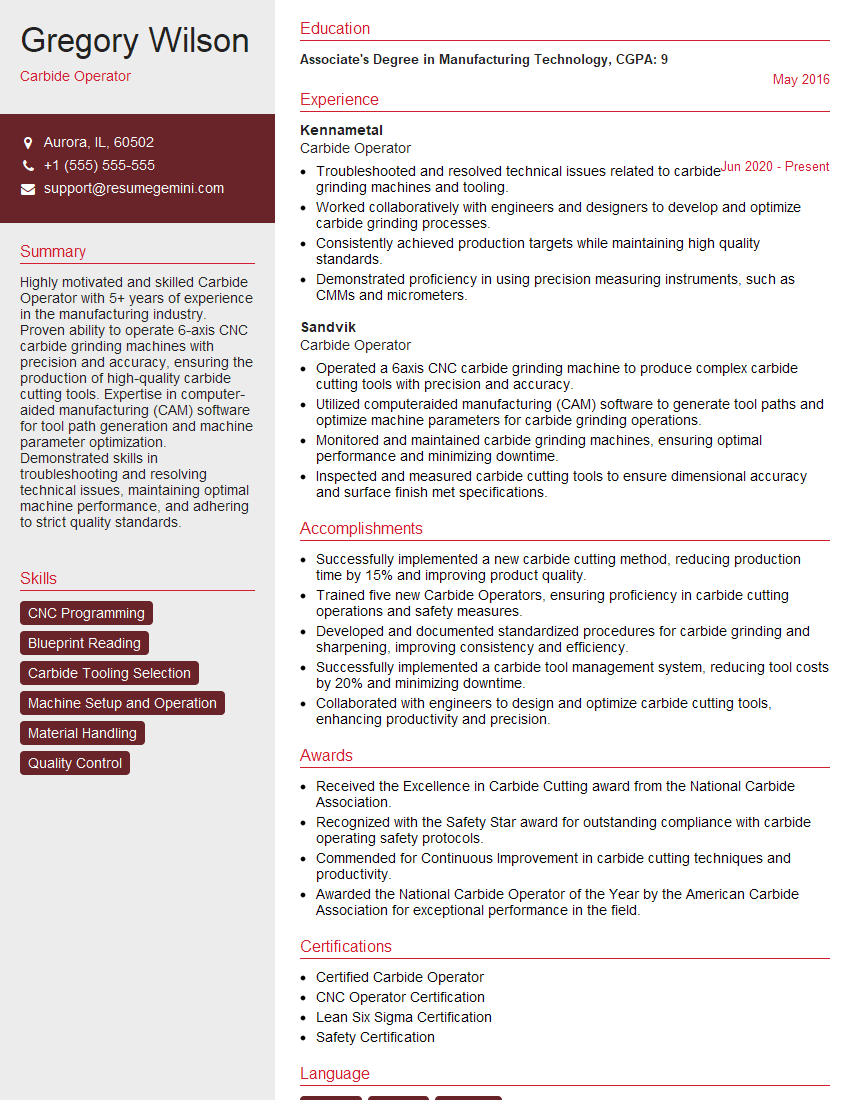

Gregory Wilson

Carbide Operator

Summary

Highly motivated and skilled Carbide Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate 6-axis CNC carbide grinding machines with precision and accuracy, ensuring the production of high-quality carbide cutting tools. Expertise in computer-aided manufacturing (CAM) software for tool path generation and machine parameter optimization. Demonstrated skills in troubleshooting and resolving technical issues, maintaining optimal machine performance, and adhering to strict quality standards.

Education

Associate’s Degree in Manufacturing Technology

May 2016

Skills

- CNC Programming

- Blueprint Reading

- Carbide Tooling Selection

- Machine Setup and Operation

- Material Handling

- Quality Control

Work Experience

Carbide Operator

- Troubleshooted and resolved technical issues related to carbide grinding machines and tooling.

- Worked collaboratively with engineers and designers to develop and optimize carbide grinding processes.

- Consistently achieved production targets while maintaining high quality standards.

- Demonstrated proficiency in using precision measuring instruments, such as CMMs and micrometers.

Carbide Operator

- Operated a 6axis CNC carbide grinding machine to produce complex carbide cutting tools with precision and accuracy.

- Utilized computeraided manufacturing (CAM) software to generate tool paths and optimize machine parameters for carbide grinding operations.

- Monitored and maintained carbide grinding machines, ensuring optimal performance and minimizing downtime.

- Inspected and measured carbide cutting tools to ensure dimensional accuracy and surface finish met specifications.

Accomplishments

- Successfully implemented a new carbide cutting method, reducing production time by 15% and improving product quality.

- Trained five new Carbide Operators, ensuring proficiency in carbide cutting operations and safety measures.

- Developed and documented standardized procedures for carbide grinding and sharpening, improving consistency and efficiency.

- Successfully implemented a carbide tool management system, reducing tool costs by 20% and minimizing downtime.

- Collaborated with engineers to design and optimize carbide cutting tools, enhancing productivity and precision.

Awards

- Received the Excellence in Carbide Cutting award from the National Carbide Association.

- Recognized with the Safety Star award for outstanding compliance with carbide operating safety protocols.

- Commended for Continuous Improvement in carbide cutting techniques and productivity.

- Awarded the National Carbide Operator of the Year by the American Carbide Association for exceptional performance in the field.

Certificates

- Certified Carbide Operator

- CNC Operator Certification

- Lean Six Sigma Certification

- Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbide Operator

- Showcase your technical skills and experience in operating CNC carbide grinding machines.

- Highlight your proficiency in CAM software and your ability to optimize machine parameters for carbide grinding.

- Emphasize your problem-solving abilities and your experience in troubleshooting and resolving technical issues.

- Quantify your accomplishments and provide specific examples of how you have contributed to improving production efficiency and quality.

Essential Experience Highlights for a Strong Carbide Operator Resume

- Operated a 6-axis CNC carbide grinding machine to produce complex carbide cutting tools with precision and accuracy

- Utilized computer-aided manufacturing (CAM) software to generate tool paths and optimize machine parameters for carbide grinding operations

- Monitored and maintained carbide grinding machines, ensuring optimal performance and minimizing downtime

- Inspected and measured carbide cutting tools to ensure dimensional accuracy and surface finish met specifications

- Troubleshooted and resolved technical issues related to carbide grinding machines and tooling

- Worked collaboratively with engineers and designers to develop and optimize carbide grinding processes

- Consistently achieved production targets while maintaining high quality standards

Frequently Asked Questions (FAQ’s) For Carbide Operator

What are the key skills required for a Carbide Operator?

The key skills required for a Carbide Operator include CNC Programming, Blueprint Reading, Carbide Tooling Selection, Machine Setup and Operation, Material Handling, and Quality Control.

What are the primary responsibilities of a Carbide Operator?

The primary responsibilities of a Carbide Operator include operating CNC carbide grinding machines, utilizing CAM software, monitoring and maintaining machines, inspecting and measuring carbide cutting tools, troubleshooting technical issues, and collaborating with engineers and designers.

What are the career prospects for a Carbide Operator?

Carbide Operators with experience and expertise can advance to positions such as CNC Programmer, Manufacturing Supervisor, or Quality Control Manager.

What are the educational requirements for a Carbide Operator?

While there are no specific educational requirements for a Carbide Operator, most employers prefer candidates with an Associate’s Degree in Manufacturing Technology or a related field.

What are the qualities of a successful Carbide Operator?

Successful Carbide Operators possess strong attention to detail, problem-solving skills, mechanical aptitude, and a commitment to quality and safety.

What are the safety precautions that a Carbide Operator should observe?

Carbide Operators must adhere to safety protocols, wear appropriate personal protective equipment, and follow established procedures to minimize risks associated with operating machinery and handling carbide tools.